In a certain sense, a sewing machine is like a human body. In order to maintain our health and longevity, it’s crucial we avoid the accident that breaks a bone and leaves us bedridden for months. Perhaps we can get away with it once or twice, but it’s certainly something we want to prevent from happening on a regular basis. Sewing machines aren’t so different. In my opinion, the best way to maintain your machine and increase its longevity is to avoid traumatic events.

With that in mind, I have decided to begin an ongoing series of articles called “Avoiding Traumatic Events.” Each article will focus on one type of traumatic sewing machine event— why it happens, the damage it does, and what we can do to prevent it from happening. In this edition of The Sewing Machine Newsletter, I will talk about the most common cause of traumatic sewing machine events that I see: failure to thread the take-up lever.

A quick review of how a stitch is made:

The function of a sewing machine is to stitch cloth together by tying a knot with two sources of thread (the upper thread spool and the bobbin thread). The successful formation of that knot is absolutely critical to the stitch-making process. Regardless of what machine you have, the knot is formed below the needle plate when the needle goes down below the needle plate hole.

As you sew, the needle goes down and the needle goes up, over and over again. As the needle goes down, the upper thread that you’ve threaded through the needle eye is taut. When the needle goes down below the needle plate and reaches its bottom-most position— what sewing machine technicians call bottom dead center— the thread is still taut. But, as the needle begins its path upwards, a thread loop forms just above the eye of the needle.

Right after this loop forms, the hook point of the sewing machine’s hook mechanism comes along and passes through the thread loop. The hook point catches the needle thread and takes it along a 360-degree path around the bobbin case. While riding along this path, the upper thread forms a loose knot with the bobbin thread. Then, as the needle reaches its high point, the take-up lever also reaches its highest point. The action of the take-up lever cinches the knot (formed below the needle plate) up into the fabric we are sewing. That, in short, is how a successful stitch is made.

The Youtube video above clearly depicts how a sewing machine forms a stitch and the critical role that the take-up lever plays in the stitch-making process. Thank you Groz-Beckert, the industrial needle manufacturer that produced this video.

What happens when we fail to thread the take-up lever?

When we don’t thread the take-up lever, the knot that is formed below the needle plate does not get cinched up into the fabric. Instead, it remains below the needle plate, hanging around the bobbin case and the hook mechanism. This is guaranteed to cause a thread tangle on the underside of your fabric (also known as bird nests). In addition, we put our machines at risk of experiencing a traumatic event.

Take-up lever & thread jams

If we accidentally forget to thread the take-up lever, we are guaranteed to get a thread tangle on the underside of the fabric. If the thread tangle gets bad enough, it can find its way below the bobbin case or hook mechanism and jam the machine. What exactly do I mean when I say “jam the machine”? I mean that the thread tangle becomes so robust that it prevents the machine from turning over properly.

For example, in the photos above, this dense ball of thread was caught behind the hook of a Bernina 7-series machine.

Similar to how a train rides upon a rail, this machine’s hook is designed to ride on a thin, finely engineered steel ledge called the hook race. You can imagine, this much thread built up behind the hook will actually push the hook forward and dislodge it from the hook race. Once the hook is dislodged out of its proper position, it is destined to make contact with all sorts of different things that it is not meant to make contact with. The hook is destined to get stuck, and this will cause the machine to jam. When I first saw this particular machine, I couldn’t turn the handwheel at all. If I continued to try to sew, there is an increased chance that the needle would strike the hook. In addition, forcing a jammed machine to sew could potentially throw the machine out of time and play havoc with a handful of other critical settings.

Fortunately, Bernina understands that failure to thread the take-up lever is a common issue, and thread tangles behind the hook are common. Therefore, Bernina has installed a sensor in many of their modern machines that senses when the hook is jostled out of place. When the sensor trips, the machine will automatically stop sewing. While this is a great feature that often saves us from ourselves., not all machines are designed with such a sensor. Therefore, we ought to be careful when threading the take-up lever, no matter what machine we own.

Take-up lever & needle strikes

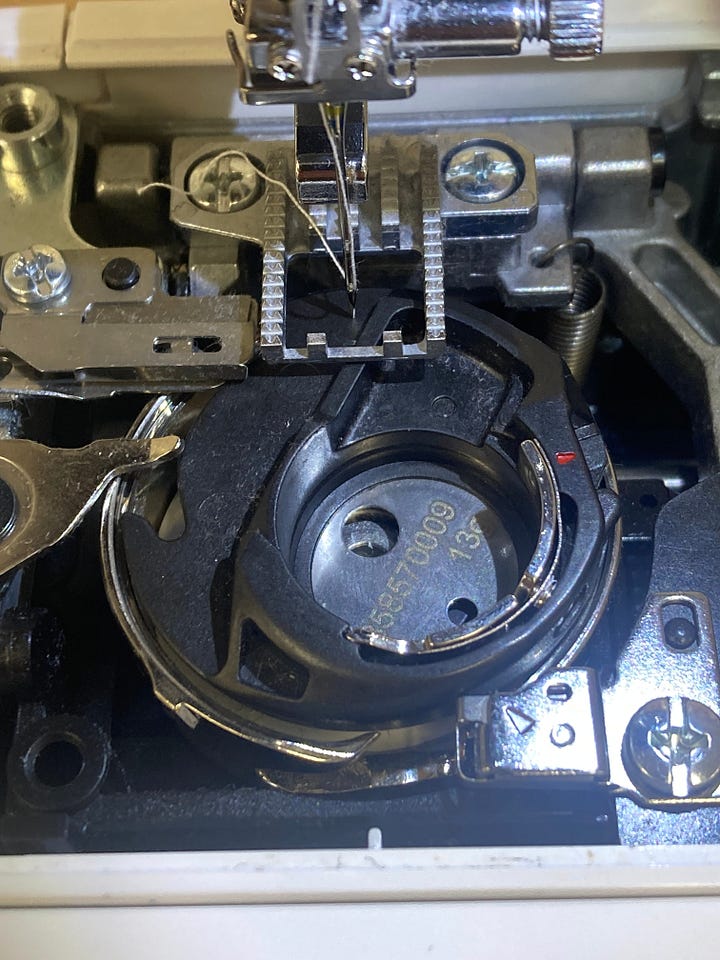

In the photos below, you’ll see a typical bobbin case for a horizontal rotary hook machine (a.k.a top-loading drop-in bobbin machine).

In the photo on the left, circled in red, a small nipple protruding from the black bobbin case sits flush with a square metal spring. This square metal spring is called the bobbin case positioning bracket, and it helps keep the bobbin case seated in the proper position as the machine sews.

If we fail to thread the take-up lever, a thread tangle can find its way underneath the bobbin case and jostle it so that the nipple passes over the bobbin case positioning bracket (as seen in the photo on the right). When this happens, there is a chance that the bobbin case will move into the path of the needle. In turn, the needle will crash into the plastic bobbin case, which is the exact type of traumatic event we want to avoid.

A needle crash such as this can potentially throw several different critical settings out of whack, such as needle-hook timing and needle bar height. In addition, you will damage your bobbin case with needle strikes. As you can see in the photos below, a bobbin case damaged severely by needle strikes must be replaced.

Other bad things that can happen:

So far I have highlighted a few of the more common and consequential problems that result from failure to thread your take-up lever. These are not the only problems that can occur. Other problems include:

The stitches on the underside of your fabric become tangled and look like a bird’s nest.

Needle breaks from striking the needle plate, hook mechanism, or bobbin case.

Fabric gets sucked down into the needle plate hole, causing the machine to jam; oftentimes the only way to remove the jam is to cut the fabric out with scissors.

Thread gets wrapped around the take-up lever linkages within the machine, which can cause the upper shaft to seize.

Thread gets jammed up around the hook mechanism, which can cause the lower shaft to seize.

What can we do to prevent this problem from happening?

It’s quite simple: when you thread the upper half of your machine, visually confirm that the thread has slid into the take-up lever eyelet.

A couple of quick notes on tips & tricks:

Utilize your machine’s needle up/down button. When you press the needle up/down button, not only will the needle go to the highest position, the takeup lever will go to the ideal position for it to be threaded successfully.

If you don’t have a needle up/down button, then turn the handwheel so that that take-up lever protrudes out from the top of the machine. This will make it easier to thread and easier to visually confirm that the thread has slid into the take-up lever eyelet.

Depending on the sewist and depending on the machine, sometimes I recommend “flossing” the thread when I reach the take-up lever. To see what I mean by flossing, please watch the Youtube video below:

Conclusion

I hope you found this information helpful. Avoiding traumatic events on your sewing machine is an underrated aspect of sewing machine maintenance and I am excited to continue this series of articles going forward.

Your feedback is always appreciated, so please let me know what think in the comments:

If there is something you find confusing or unclear, I can always edit the article and you will have better information in the future when you return to the archive.

“What archive, Cale?”

Thank you for asking. By archive I mean the archive of every article we’ve published so far, which you can find by clicking on the ARCHIVE button below:

Lastly, if you like what you see, please feel free to share these articles with any and all sewists you know:

Thank you for reading. I appreciate you all.

-Cale

My Janome suffered from needle strike to the bobbin case, my own fault. I thought it would sew denim hems like my vintage Elna did. Nope. Just have to pick the machine to use for each sewing job now. I find any slight jam up is invariably due to me not holding the threads at the start, then thread jumps out of take up lever and things go south. So I rethread everything at a jam.

I have found that machines with drop in bobbins are much more “ fussy” than machines with front loaded ones.