Calculating the Power of a Sewing Machine

A breakdown of wattage, motor strength, and why feel still matters more than specs.

How Powerful Is a Sewing Machine?

Working at The Sewing Machine Shop, when customers compare sewing machines, one of the most common questions I hear is:

“Which machine is the most powerful?”

At first glance, it sounds like a simple question. But what exactly do we mean by “powerful”?

Do we mean the machine that sews the fastest?

The one that punches through thick denim or leather with ease?

The machine that lasts the longest over years of hard use?

Each of these is valid, but none are captured by a single statistic. In this article, I want to unpack the concept of sewing machine power and walk you through how to better understand what makes one machine feel more powerful than another.

What Is Power?

In physics, power is defined as the rate at which energy is transferred or converted. The standard unit is the watt (W), which measures how quickly energy is used.

For electric sewing machines, we calculate electrical power like this:

Power (Watts) = Voltage (Volts) × Current (Amps)

This formula tells us how much electrical energy the machine is consuming. But power consumption doesn't always reflect mechanical output or "sewing strength."

Where to Find Wattage on a Sewing Machine

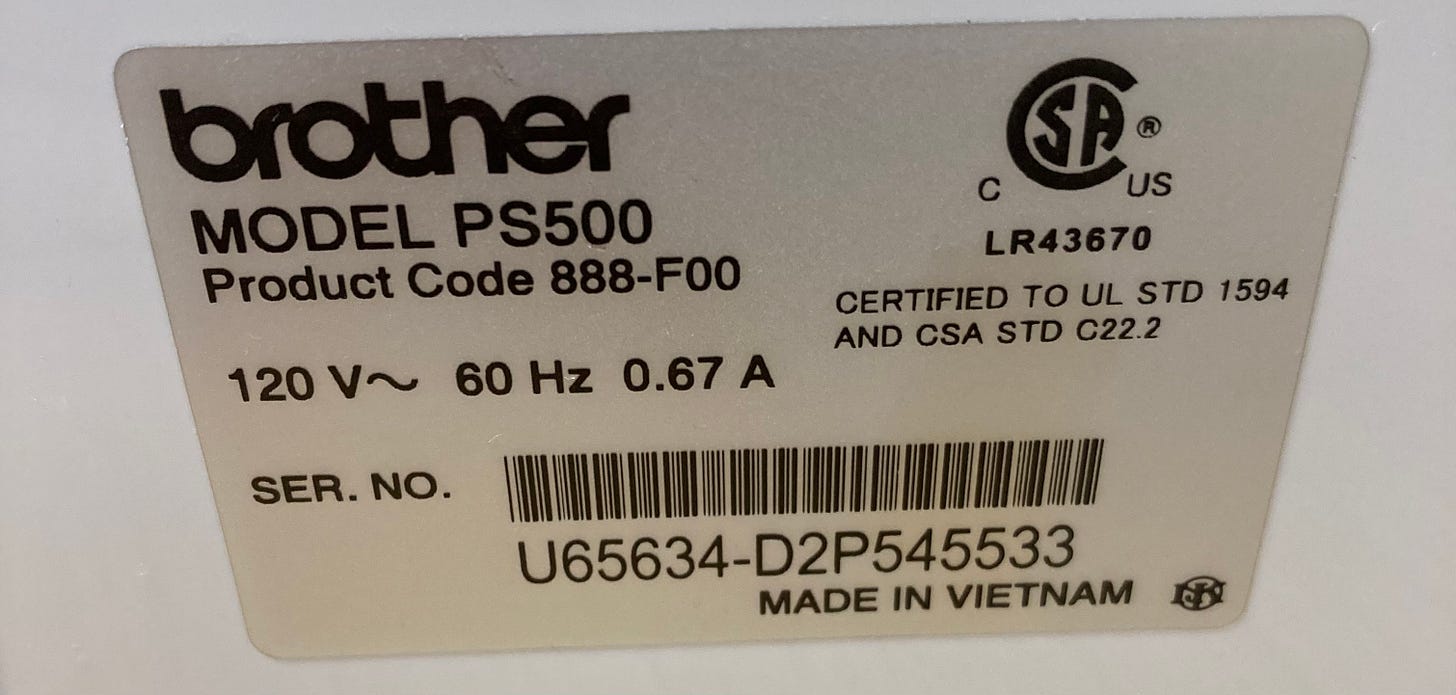

On the back of nearly every modern sewing machine, you'll find a metal tag showing its:

Model and serial number

Voltage (usually 120V in North America)

Current (in Amps) or sometimes total wattage

Multiply voltage by amperage and you get the electrical wattage.

Here are a few examples:

The machines I subjectively view as “strongest”— the M7, TL-18, and B770— are also among the highest in wattage. This shows that power ratings can be a useful indicator up to a point.

Why the Math Doesn’t Always Add Up

Let’s look at a Janome HD3000, a mechanical workhorse that's been around for years.

On older HD3000’s, the back tag listed 1.0 amps (120W). But newer models say 0.8 amps (96W). Did the machine get weaker?

No. Janome simply started using more efficient LED lights inside the machine. The light bulb drew less power, so total amperage dropped, even though the motor and mechanical performance stayed the same.

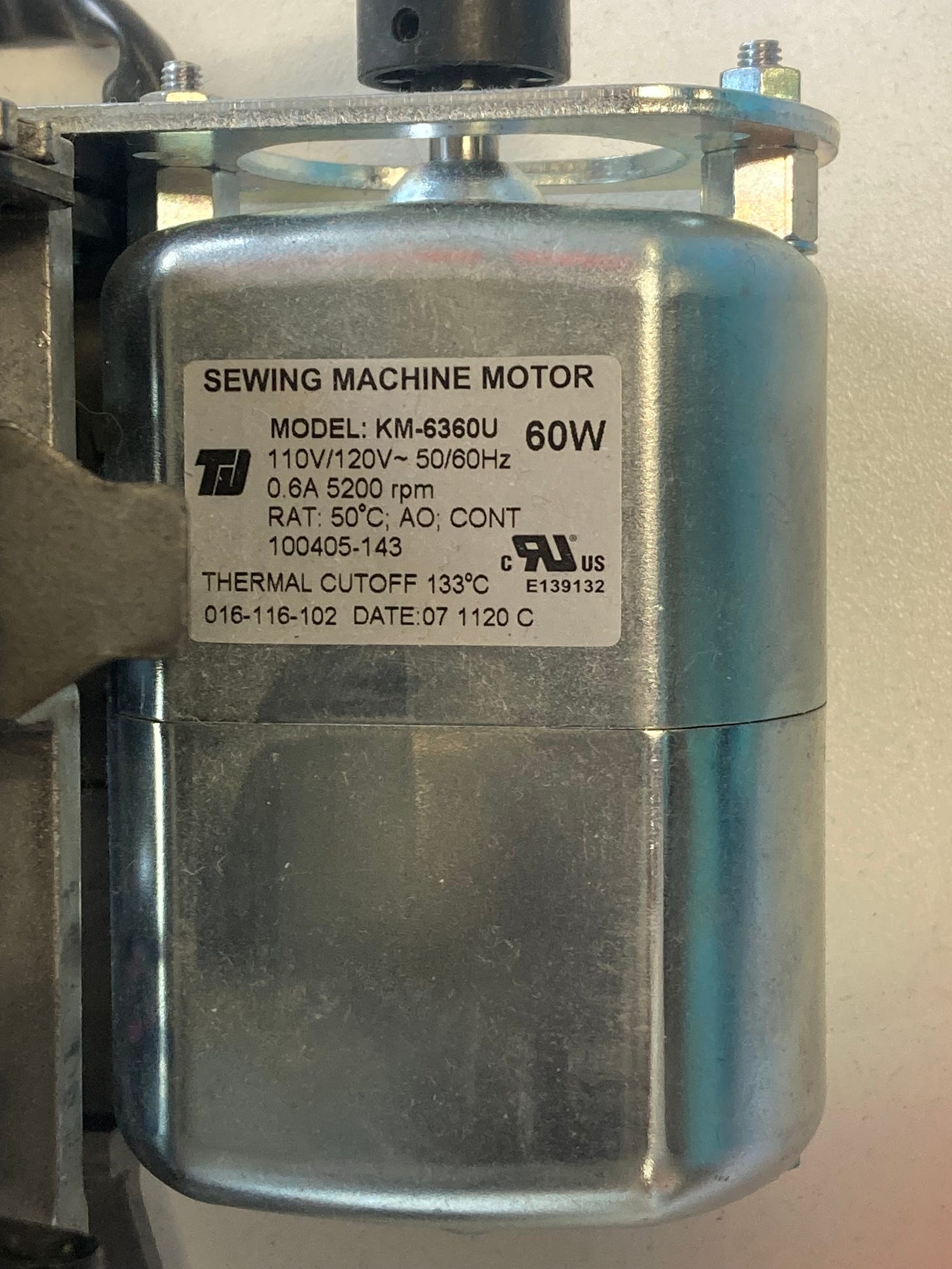

This brings up a critical point: the electrical power listed on the back of a machine includes everything inside it—motor, lights, electronics. It’s not a direct readout of the motor’s mechanical power.

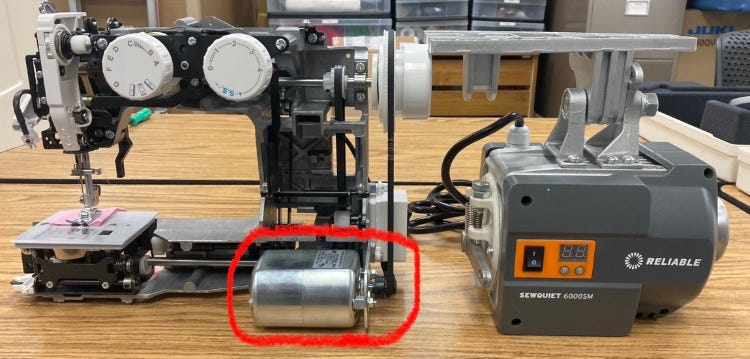

Sometimes, the motor itself will be labeled inside the machine. For example, a Baby Lock Joy shows 0.38A × 120V = 45.6W on the back of the machine. But inside, its motor is labeled 60W— because that’s just the motor’s power, not the total system draw.

Energy Loss and Mechanical Efficiency

Even if two machines have identical wattage ratings, they may perform very differently. Why?

Because power isn’t just about input— it’s about what you do with it.

Every machine has some degree of energy loss, where electrical power doesn’t make it to the needle. This can be due to:

Friction in gears and shafts

Resistance in wiring or motor windings

Heat loss from inefficient components

Loose tolerances or sloppily engineered drive systems

Machines with smoother drive trains**, better bearings, tighter tolerances, and well-tuned shafts will feel stronger and more responsive, even if their wattage is lower.

This is why a modern Bernina 570 with a 90W tag can outperform a vintage Kenmore with 120W. It’s not about raw input. It’s about design efficiency.

**A drive train in a sewing machine refers to the system of mechanical components that transfers power from the motor to the needle and feed mechanisms. It’s what converts the motor’s rotation into the precise, timed movements needed to make a stitch.

The Missing Stats: Torque and RPM

In the world of motors, two numbers are just as important as watts:

Torque: the twisting force delivered by the motor

RPM: how fast the motor spins

These values help define the “feel” of the machine. A motor with high torque at low RPMs will feel strong, especially at slower sewing speeds. Unfortunately, sewing machine manufacturers rarely publish this data, so we’re left to infer performance from wattage and user experience.

Fun fact:

1 horsepower = 746 watts

So a 150W sewing machine motor delivers about 0.2 horsepower, which is pretty substantial for a home appliance.

The Verdict: How to Judge Power

If you're evaluating sewing machine power, here's what to consider:

Check the back tag

Multiply volts × amps for a rough estimate of power. It’s a good starting point.Understand the context

A high-wattage machine with poor internal design may underperform. A lower-wattage machine with precision engineering may feel surprisingly strong. So don’t obsess over numbers. Use wattage as a reference, not a final verdict.Go by feel

Try the machine on dense fabric. The way it handles layers, its sound under load, and its stitch consistency tell you more than a spec sheet.

Final Thoughts

There’s no one number that captures how “powerful” a sewing machine truly is.

The motor matters, but so does the mechanical design, the build quality, and the efficiency of how energy is transferred from the motor to the needle.

Ultimately, feel is king. And that’s something you only get by sitting down at the machine and sewing.

Thank you for reading!

If you found this article interesting, please share with you fellow sewists.

Thank you,

—Cale

My husband is an electrical engineer and this is a topic that we have discussed. I am influenced at times by the advertised language that may not be incorrect, but leads the customer to an assumption. Your clear, factual information is an important service to all your readers. Your devoted reader.😊

Another outstanding read of information you never see written about regarding sewing machines. I value your knowledge and look forward to more fascinating articles.