Every year after Christmas, we typically see an influx of machines come into The Sewing Machine Shop in need of a tuneup and/or repair. This year feels crazier than usual. As I write this on January 19th, we find ourselves amidst a 3 week-long tsunami of machines.

The vast majority of machines we see simply need a general service, which we refer to as a COA (Clean, Oil, Adjust). When one of our technicians performs a COA, he removes the plastic covers to expose the machine’s housing and internal components. From there, he cleans out all lint and dust with compressed air, lubricates the metal-on-metal moving parts that call for oil, then goes through a checklist of ~25 primary adjustments that affect the performance of the machine and its ability to make a quality stitch. If you want a more detailed look at what a COA entails, you can read a previous article I wrote titled The Sewing Machine Technician’s Checklist.

Not all machines come to us for a general COA service. Occasionally we get a machine that has a specific problem that needs to be fixed. For example, a Bernina 770 that keeps giving an error message that the upper thread is broken, even though the upper thread is not broken. Or, another example could be if an older mechanical machine is stuck in reverse. In both cases, the machine’s owner just wants the specific problem fixed and does not want to pay for a full service. Fair enough — our guys can take care of that, no problem.

Recently, somebody came into the shop and dropped off their Brother-built embroidery-only machine that was presenting a strange problem. This is what was written down on the repair ticket:

NO COA.

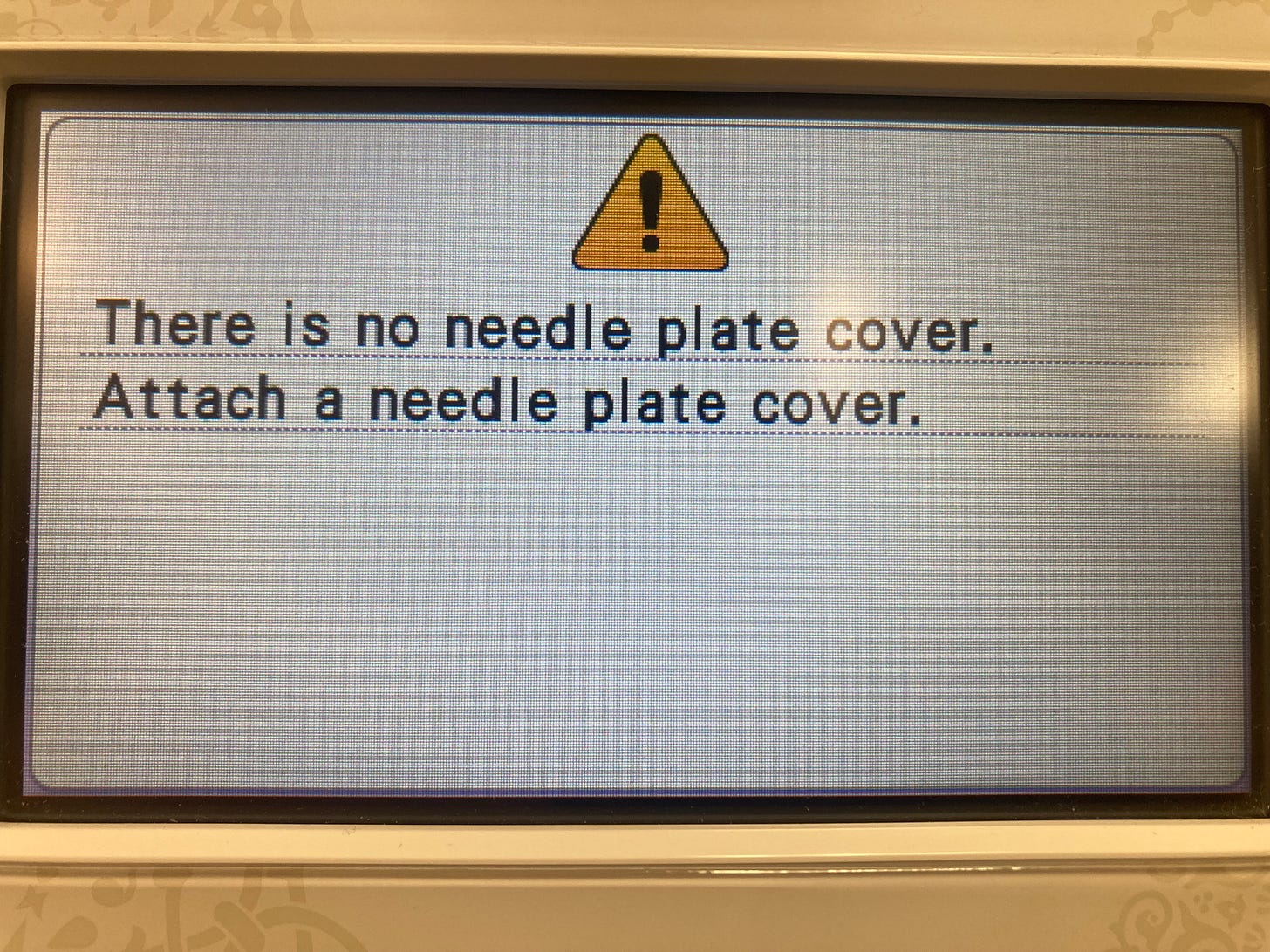

WHEN YOU TURN ON THE MACHINE AN ERROR MESSAGE APPEARS ON SCREEN THAT SAYS “NEEDLE PLATE COVER NOT ON MACHINE” EVEN THOUGH NEEDLE PLATE COVER IS ON MACHINE.

Sure enough, when the machine was turned on, this is the error message that was shown on the screen:

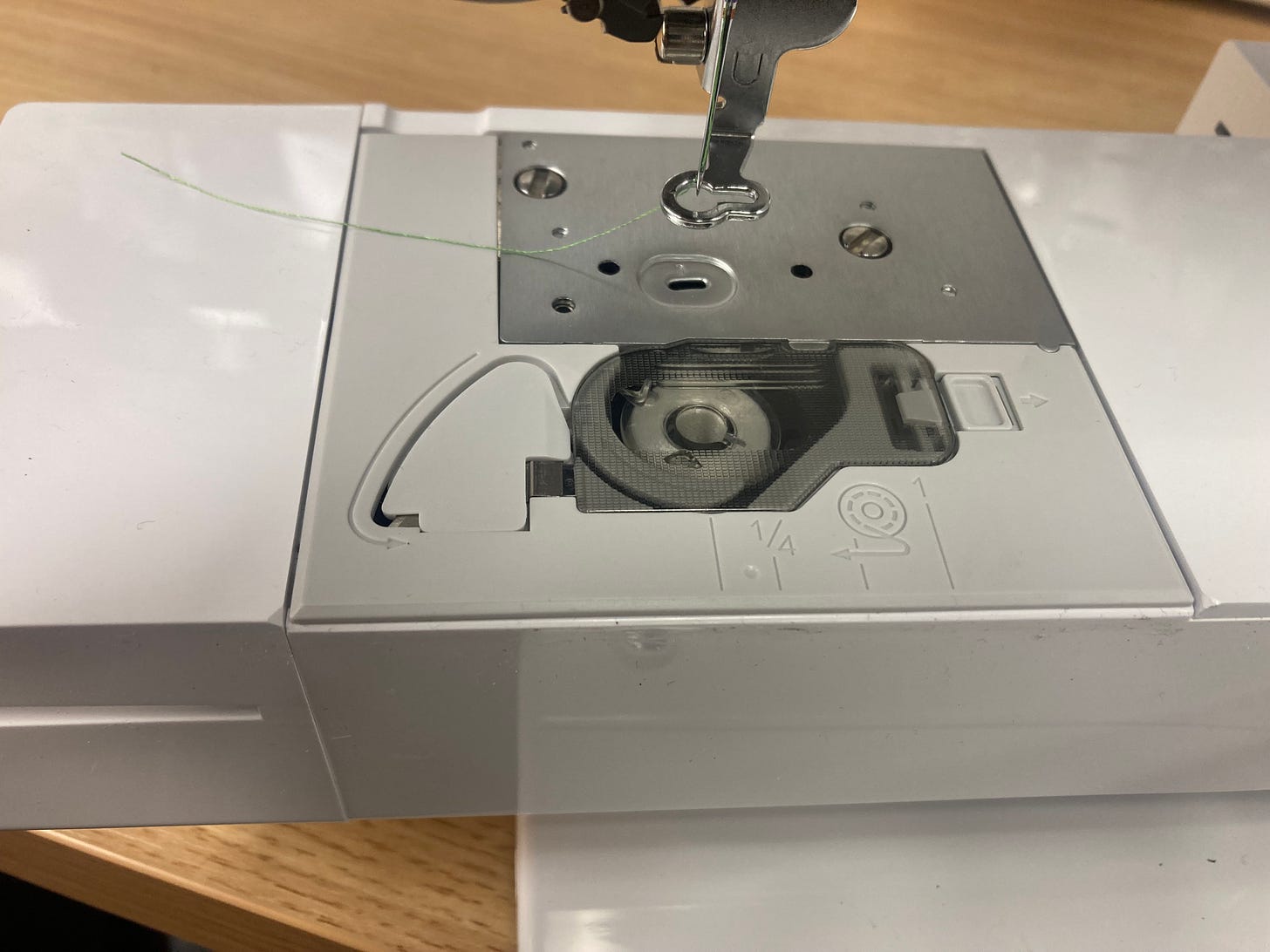

But, as you can see in the photograph below, the needle plate cover was on securely on the machine:

We have seen this problem a couple of times before. In the past, the error message popped up because the sensor that senses the needle plate was askew and out of position. But, in this case, that sensor was perfectly fine.

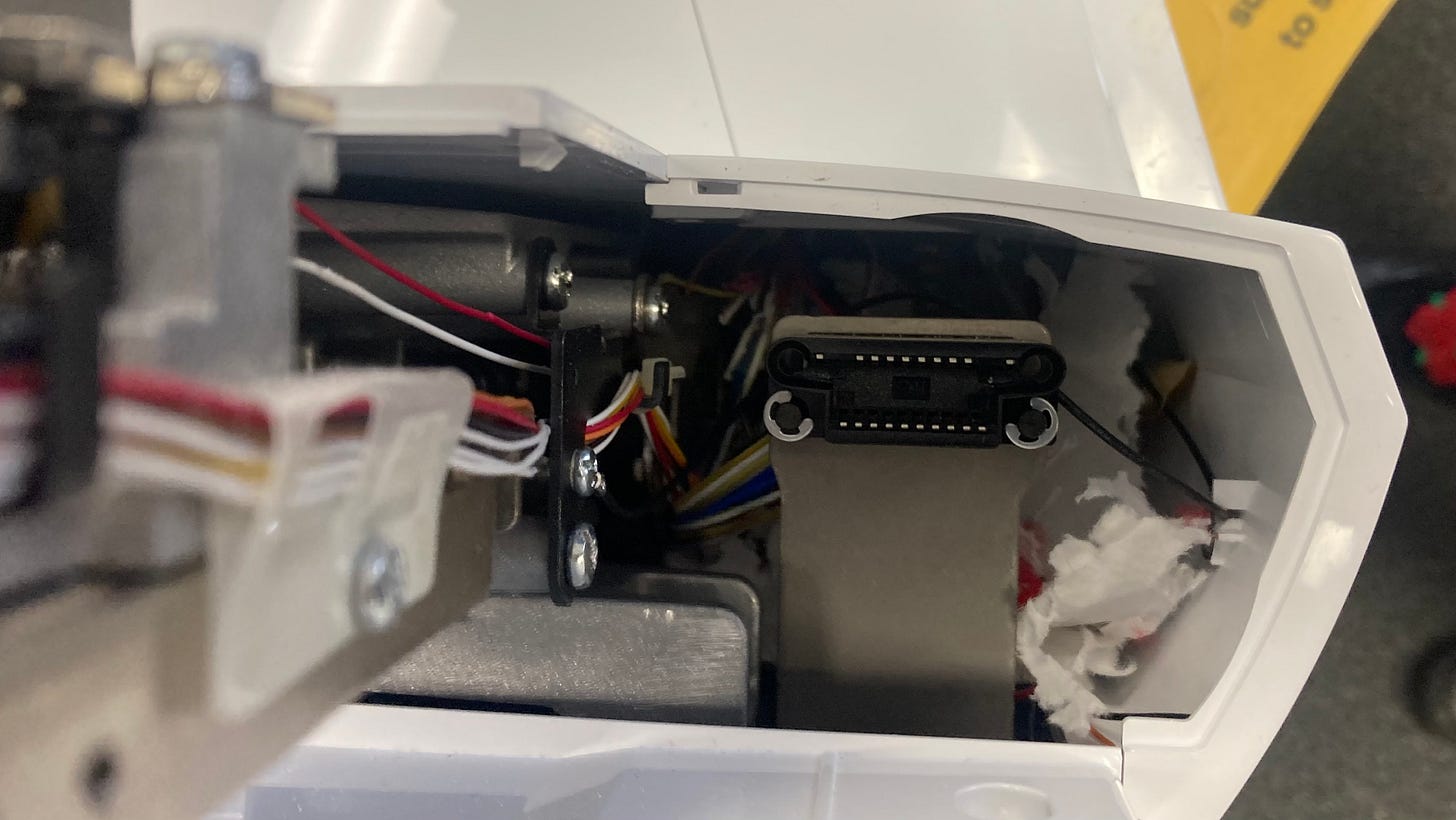

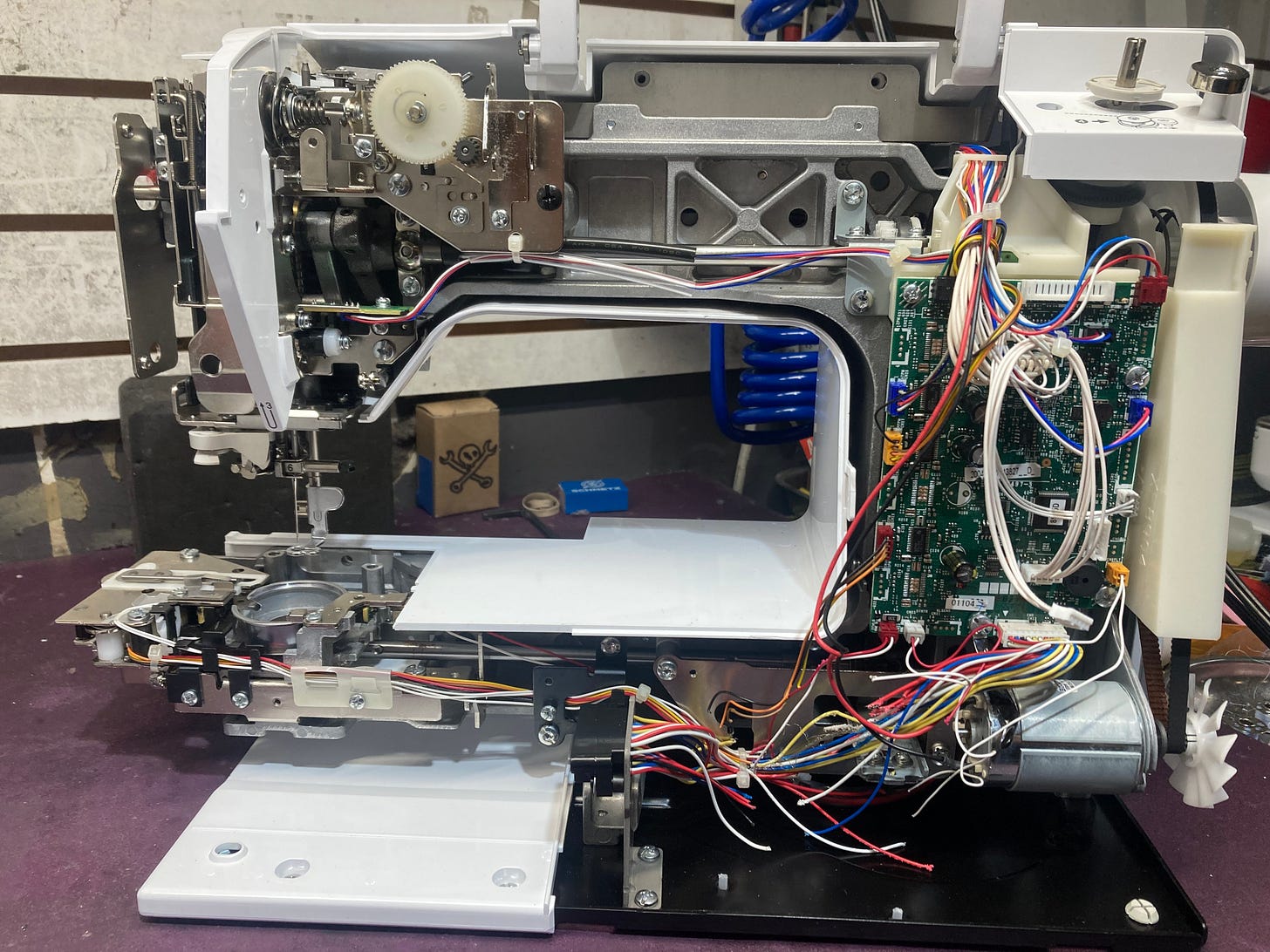

From here, it is clear we have a bit of a mystery on our hands. We had to open up the machine for further investigation…

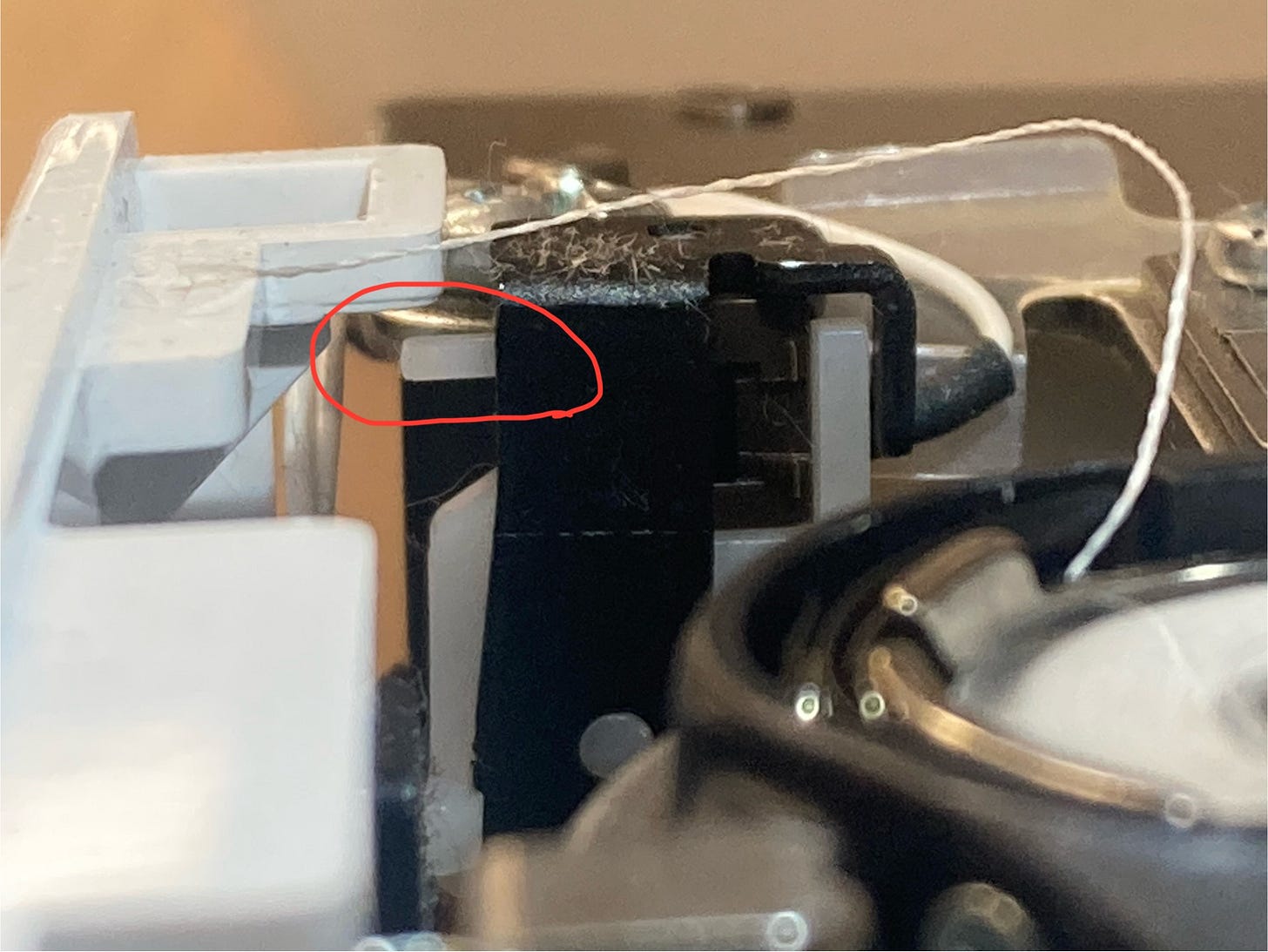

Once the machine was opened, it did not take long to figure out what was happening. Within the machine, there is a gap of space between the plastic cover and the machine’s housing. That gap was full of torn-up paper, stabilizer, thread, and other miscellaneous bits —a nest.

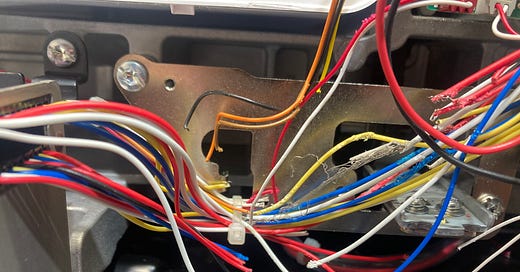

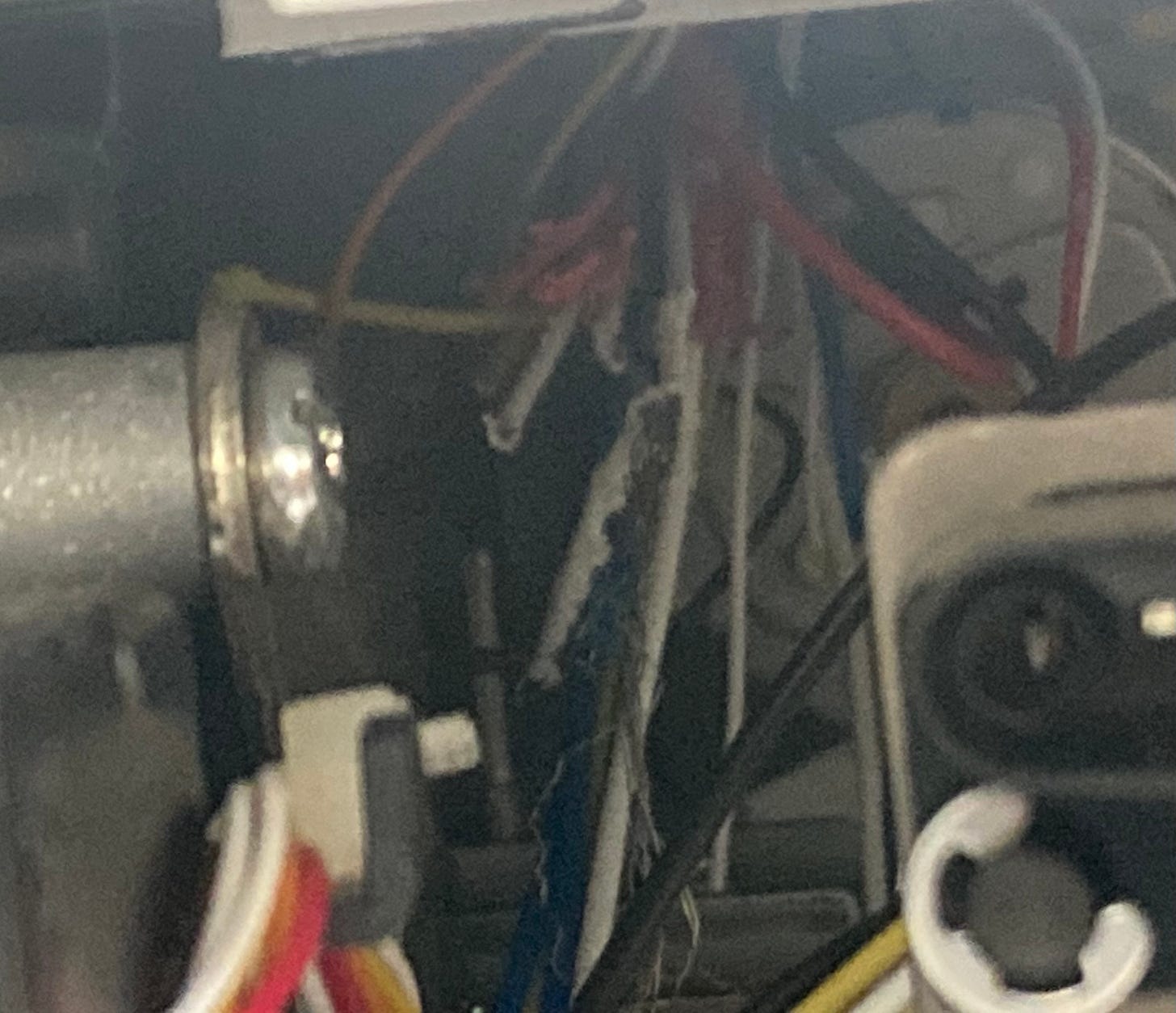

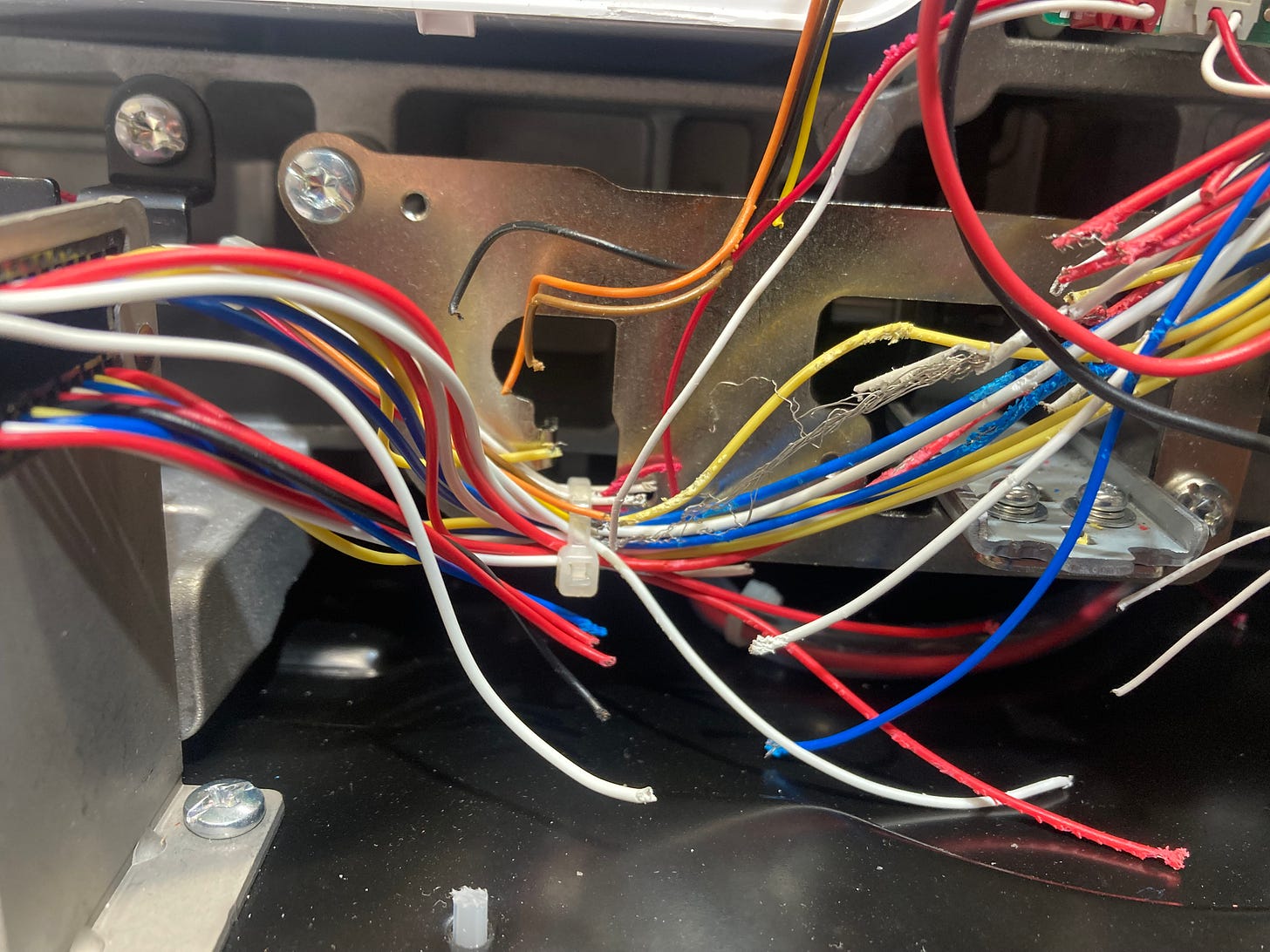

The nest itself was not the problem. The problem was that the critter who built the nest had also decided to chew through the machine’s wiring:

Danny, one of our lead technicians, worked as a car mechanic before taking his talents to sewing machines. The scene inside the sewing machine looked all too familiar to him.

“That’s a mouse nest,” he said. “Without a doubt. I used to see them in cars all the time. They get inside and build a nest out of all sorts of junk. Always end up chewing through the wiring. A couple of times in cars, if the mouse chewed a live wire I’d find them in there torched, dead as a doornail.”

Fortunately, there were no dead rodents inside the machine. But you can’t help but wonder, how did the mice get inside the machine in the first place? We don’t know for sure, but we have a theory…

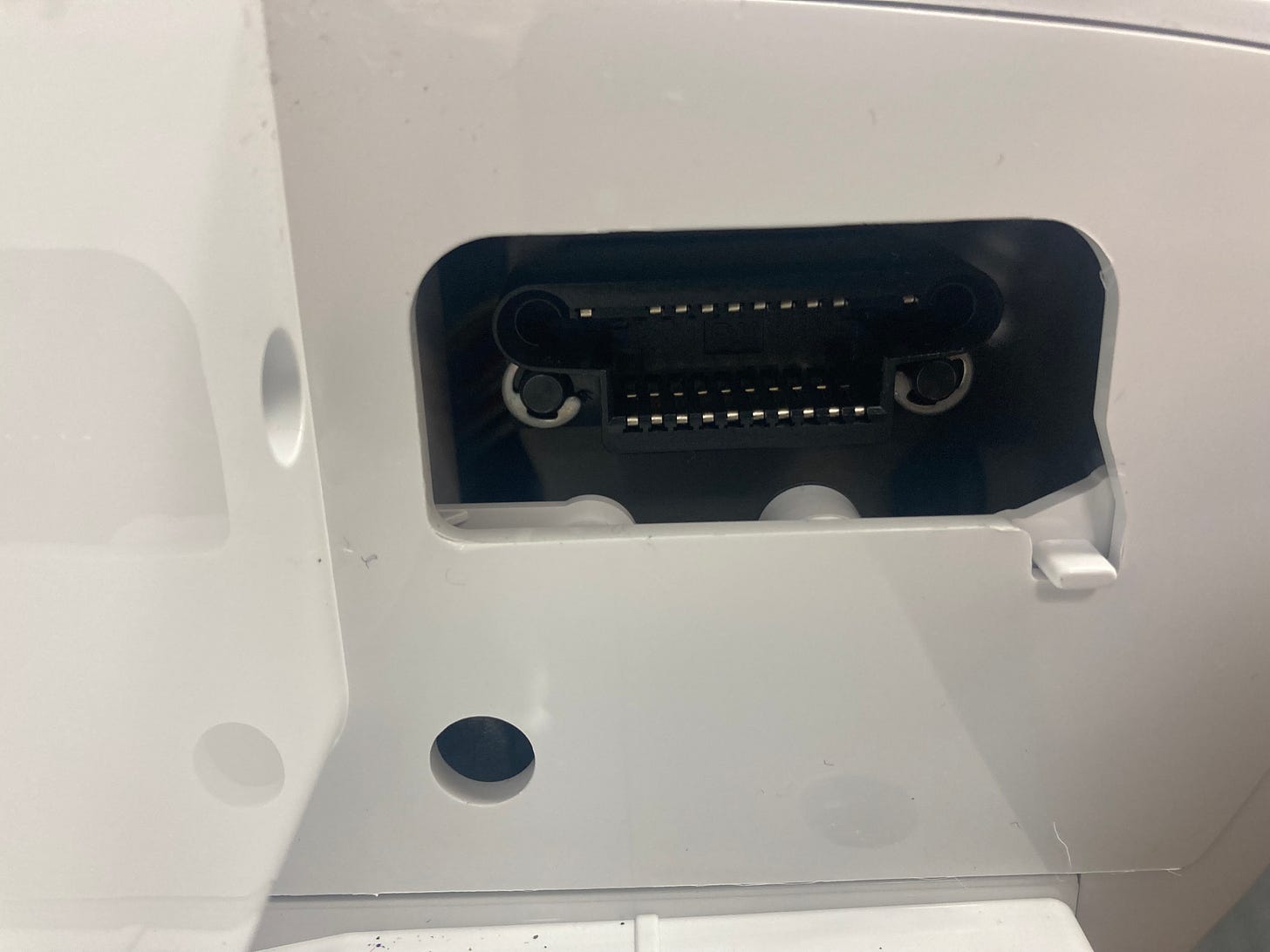

On the surface, there does not appear to be an obvious place where a mouse could crawl into an embroidery machine:

However, when the embroidery unit is separated from the machine, the connection point where the embroidery unit connects to the machine is essentially an open door to the inside:

We suspect that this is how the mice got inside. It doesn’t look very big, but mice can squeeze through just about anything.

Can The Machine Be Fixed?

Right now, this machine is toast. Even if the needle plate sensor was still working properly, the damage to the wires is extensive and would lead to other problems.

The good news is that we should be able to order new wiring for the machine. Rewiring the machine isn’t a quick job by any means, so parts and labor to get it completely fixed won’t be cheap. However, for a high-quality embroidery machine like this one, I think it’s worth the money to get it fixed.

This is not the first time that we’ve found something strange inside a sewing machine, and it won’t be the last. Dead bugs and cockroaches seem to pop up a few times every year. About 6 months ago, we even found a black widow living inside a foot pedal!

Anyway, I hope you found this article interesting.

Thank you for reading.

-Cale

Sewing machine technician-sleuth = 1 point, mouse = 0😂😂😂😂

Good article!

We have a squirrel problem with car engines. It was an expensive fix, too. We use rodent spray now.