Let's Talk About Walking Feet

A detailed breakdown of sewing machine walking feet, why it's useful to use one, & common misconceptions.

Greetings everybody,

On this edition of The Sewing Machine Newsletter I want to talk about walking feet. My goal for this article is as follows:

Explain why one would want to use a walking foot in the first place.

Compare and contrast the walking foot one would use on an entry-level sewing machine to the walking foot one would use on a “premier” sewing machine (~$1,500 and up, depending on the manufacturer).

Clear up a few misconceptions I hear floating around the ether.

Why use a walking foot in the first place?

As a sewing machine sews, it feeds the fabric forward a designated length of space between each stitch— stitch-feed-stitch-feed-stitch-feed. The presser foot holds the fabric down against the gripped feed teeth (also known as feed dogs) which are positioned below the needle plate. As the needle goes up out of the fabric, the feed dogs rise just above the needle plate surface and move to feed the fabric forward. When the needle goes back down into the fabric to make the next stitch, the feed dogs disappear momentarily below the needle plate. And so it goes… stitch-feed-stitch-feed-stitch-feed.

When we use a sewing machine, we are typically sewing multiple layers of fabric together. The feed dogs only make contact with the bottom layer of fabric, not the top layer. Because the bottom layer of fabric is in contact with the gripped feed teeth and the top layer is not, a potential problem is that the bottom layer of fabric may feed at a slightly different rate than the top layer. I've heard many people, particularly quilters, refer to this problem as slippage.

In essence, a walking foot is a presser foot with gripped feed teeth— gripped teeth that make contact with the top layer of fabric. The basic idea is that you can combat slippage and achieve a more even feed between multiple fabric layers by using a walking foot because you now have gripped teeth feeding both the bottom layer of fabric AND the top layer.

The concept is easy enough to understand, but this brings us to a larger conversation about the different types of walking feet that are out there. Today I am going to talk about 3 different types, and I believe that by comparing and contrasting the different types we will come to a better understanding of the walking foot landscape.

(1) Basic Entry Level Walking Foot

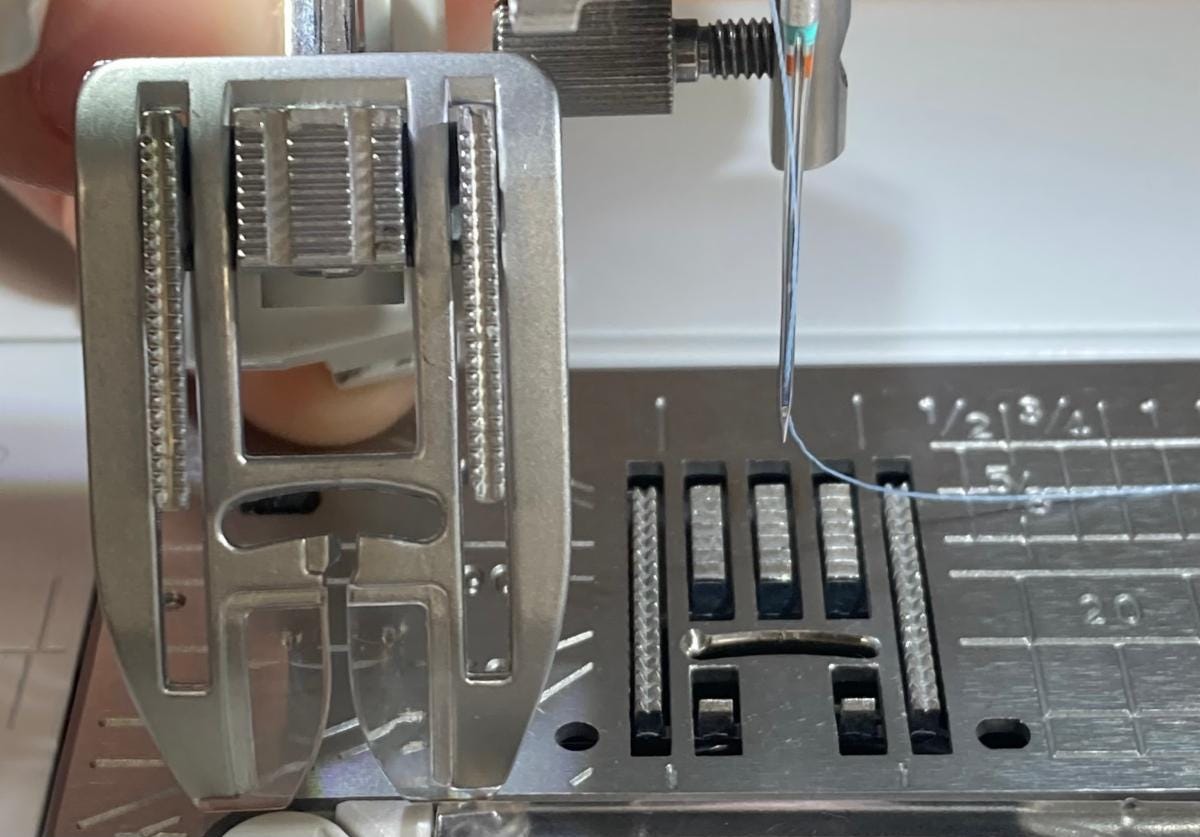

The photo below shows the basic walking foot you'll find on nearly every machine that costs less than $1,500:

There are a few things I want you to notice.

First, notice how the walking foot has a lever that goes around the needle bar set screw. The walking foot is designed like this because the movement of the walking foot's gripped feed teeth is dependent on the needle bar moving up and down. In other words, the walking foot reacts to the needle movement.

The second thing I want you to notice is the gripped feed teeth on the walking foot itself:

The teeth are made of plastic, which is fine, but not ideal.

Watch the video above to see this style of walking foot in action.

(2) Janome's "AcuFeed" Dual Feed Foot

This walking foot from Janome is one of the most underrated features in the sewing machine world. I'm surprised there is not more buzz about it. In my opinion, Janome’s marketing department needs to step up their game, because their engineers already have. Janome calls this walking foot the AcuFeed Dual Feed Foot, and I would argue that it is perhaps the best-performing walking foot ever created.

As you can see in the photos above, this walking foot is not designed in the same way as the basic entry-level walking foot. The foot’s gripped feed teeth are made of metal instead of plastic, and they nearly mirror the traditional feed dogs’ gripped teeth to a tee. More importantly, there is no lever that goes around the needle bar screw, meaning that the action of the walking foot's gripped feed teeth is not dependent on the movement of the needle bar. That begs the question-- how does the walking foot's gripped teeth move?

As you can see in the photo above, the Janome AcuFeed walking foot hooks into a mechanism in the back of the machine. Remember that thing about the thigh bone connects to the knee bone, the knee bone connects to the shin bone, and so on? The same principle applies here. The walking foot is hooked into a mechanism that connects it to the upper shaft of the machine. The upper shaft is connected to the motor belt and the motor belt is connected to the lower shaft. And guess what the lower shaft is connected to? The machine’s feed dog mechanism.

This gives Janome’s Acufeed walking foot the distinction of integrated dual feed. Because the AcuFeed foot is directly hooked into the machine’s critical internal components, the gripped feed teeth operate completely in sync with the machine's feed dogs, which helps deliver a more even feed than a basic entry-level walking foot. With integrated dual feed, both the top layer and bottom layer of material feed at the same rate.

Not only does it help prevent slippage, not only does it deliver a more even feed when sewing multiple layers of fabric, it does a third thing that is really unique.

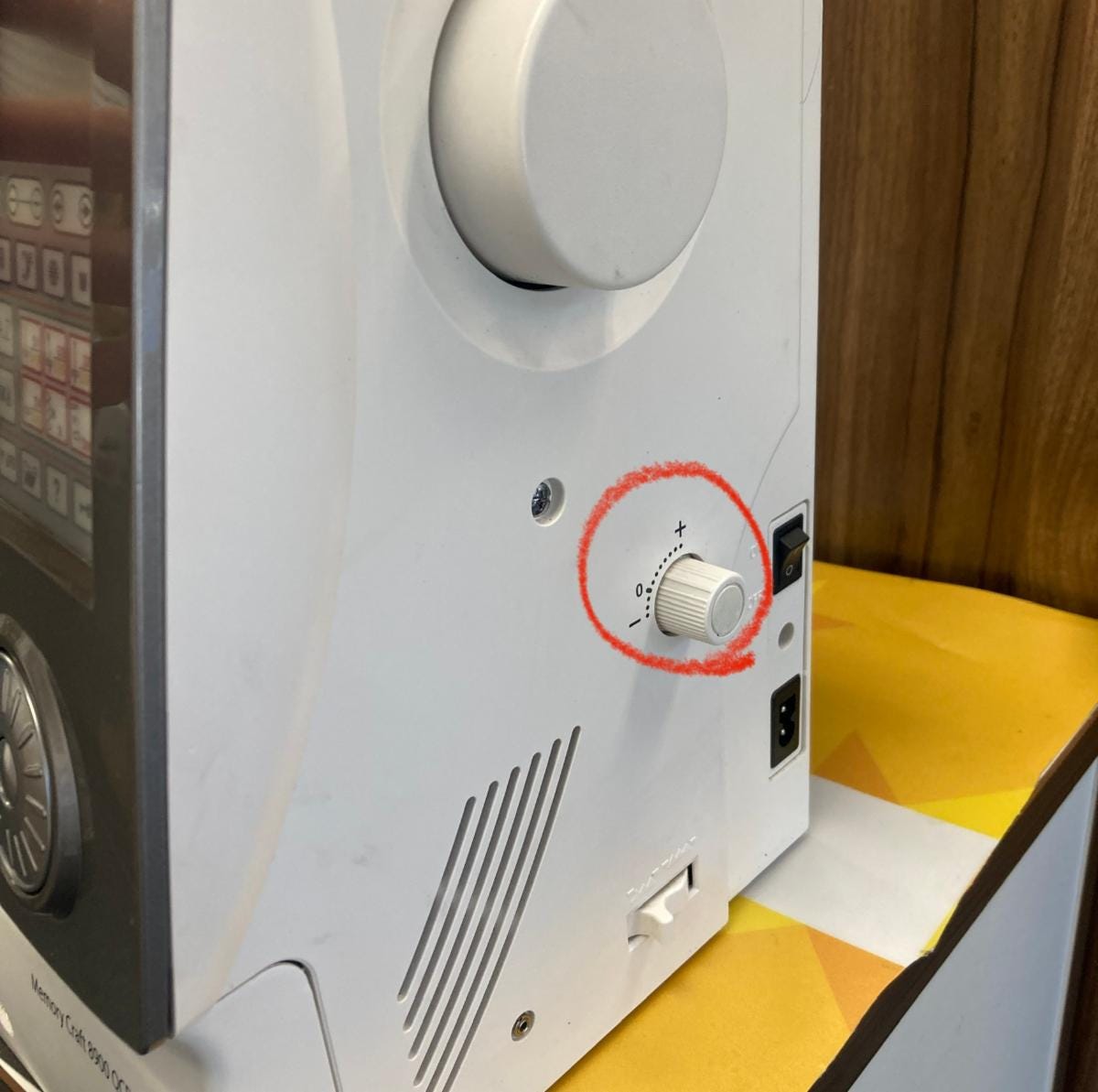

A machine that is compatible with Janome's AcuFeed walking foot will have a knob on the right side of the machine, which you can see in the photo above. This knob allows you to adjust the feeding ratio between the Acufeed walking foot and the feed dogs. This ability to adjust the feeding ratio is what we call differential feed. Most of you will be familiar with sergers, which are particularly suited for sewing knits. One reason is they use a chainstitch instead of a lockstitch, which is a story for another day. But another reason is that they are designed with two sets of feed dogs below the needle plate and the ability to adjust the feed ratio between the two feed dogs— also known as differential feed. Until Janome invented the AcuFeed walking foot, sewing machines were not capable of differential feed. Now they are, making them better suited for sewing knits and stretchy fabric.

As you can probably tell, I love Janome's AcuFeed walking foot. I'm a huge, huge, huge fan. What I love even more is that you don't have to buy their top-of-the-line machine to get it. While they put the AcuFeed walking foot on their $15,000 M17 super-machine, they also put it on the Skyline S6, which costs ~$1,500 new. It’s an incredible deal on an incredible machine, and arguably the most cost-effective machine on the market. More people need to be aware of it.

***** Just to be clear, Janome machines between the M17 and S6 are also equipped with Acufeed. *****

(3) Bernina's Built-in Dual Feed

Bernina has an integrated walking foot of their own, which is commonly known as "built-in dual feed."

As the name implies, this version of a walking foot is built into the machine. The benefit of this design is that it is super easy to engage the walking foot. All you have to do is pull the dual feed down into the presser foot and you’re ready to go.

Those of you who have used the traditional style walking feet before will know it can be a bit of a pain to remove the entire presser foot and ankle, then have to screw on the walking foot while also getting that lever around the needle screw bar. With Bernina's built-in dual feed, you won't have to pull out a screwdriver to put it on and take it off. There is no struggling to get the walking foot lever over the needle screw. You simply pull down the dual feed to engage it, and you push it back up to disengage it.

Similar to Janome's AcuFeed system, Bernina's built-in walking foot also meets the criteria to be classified as integrated dual feed. It does not have as many gripped feed teeth as the Janome version, but the teeth are made of metal and do a very good job. Another unique thing about Bernina's built-in dual feed is that it is compatible with a ton of different feet. If you see a Bernina presser foot with the letter 'D' after the number, that means it is compatible with the built-in dual feed.

The one downside of Bernina’s built-in dual feed is that the machines that have it are rather expensive. As far as I’m aware, at the time I write this newsletter the least expensive Bernina machine that offers built-in dual feed is the B570, which sells for well over $4,000.

If someone wants a quality machine with built-in dual feed, but does not want to spend thousands of dollars, they should consider a vintage Pfaff machine from 80’s/90’s/early 2000’s— e.g. 7550, 2140, 2022, etc.

A few more points to make…

Top-of-the-line machines from Baby Lock and Brother have a special “tractor" style walking foot that is rather unique. Instead of the walking foot having gripped feed teeth, it has this rubber belt that pulls the top layer of fabric in order to achieve an even feed.

It’s a unique design and a bit more bulky than the other dual feed systems discussed so far, but I know a lot of people who use this tractor-style walking foot and like it a lot.

One last thing I want to discuss is whether or not a walking foot helps us sew thicker layers of fabric. I’m sure some people will disagree with me, but my answer is no. The function of a walking foot is not to give the machine the ability to sew thicker layers of fabric. The function of a walking foot is to achieve a more even feed between multiple layers of fabric. It serves as an aid to the machine’s feeding mechanism; it does not make the machine more “heavy duty” because it has nothing to do with the needle penetrating the material and the knot being set in the material.

A machine’s ability to sew thick fabrics depends on the quality of the critical internal components, the power of the motor, the take-up stroke, and more. I think this misnomer may have to do with walking foot industrial machines like the Juki DNU-1541, which actually feed the fabric with the needle down in the fabric, a completely different design from home sewing machines.

I hope you found this information helpful. I’d love to hear about what types of walking feet you like or dislike in the comments, your experience with different dual feed systems, or any other input or questions you might have. Also, if you like what you see, please feel free to share it with any sewists you know in person or on Facebook.

Thank you,

-Cale

Thanks, this was very interesting. As an old-school sewer, I have never used one, although I do own a vintage Kenmore one. I really appreciate your use of video. It's so helpful to see exactly what's happening.

I was first introduced to dual feed when I bought a Pfaff Creative 1471 in 1987. Loved it! I never want to be without. I've since purchased a Bernina 770QE+ and in my opinion Bernina's built-in dual feed does not measure up to the Pfaff. I'm very interested to check out the Janome ... and the differential!

I'd be interested in an article explaining differential ratios in depth, and how all that works. Your videos are very helpful. Thank you!