The Beauty of a Powder-Coated Sewing Machine

…and what it says about the company that does it

Greetings everybody,

Today’s article is special, as it is the first piece written by the new contributing author to The Sewing Machine Newsletter, my father and mentor, Dan Schoenberg. He has owned a sewing machine dealership for over 35 years, operating both as the chief salesman and head technician. He’s a true wealth of knowledge and there’s no doubt you will learn a lot from reading him.

Initially, my intention was to make all of my dad’s articles exclusive to paid subscribers of the newsletter. I still plan on doing that in the future, but I’ve made this particular article free to everyone because I consider it a public service announcement. Previously, a detailed explanation of powder-coated sewing machines did not exist on the internet. It does now.

I hope you find it interesting.

-Cale

The Beauty of a Powder-Coated Sewing Machine

… and what it says about the company that does it

by Dan Schoenberg

Before I talk about what powder coating is and how it makes a sewing machine better, I want to emphasize that the benefits of a powder coated sewing machine pale in comparison to what the powder coated sewing machine reveals about the company that does it.

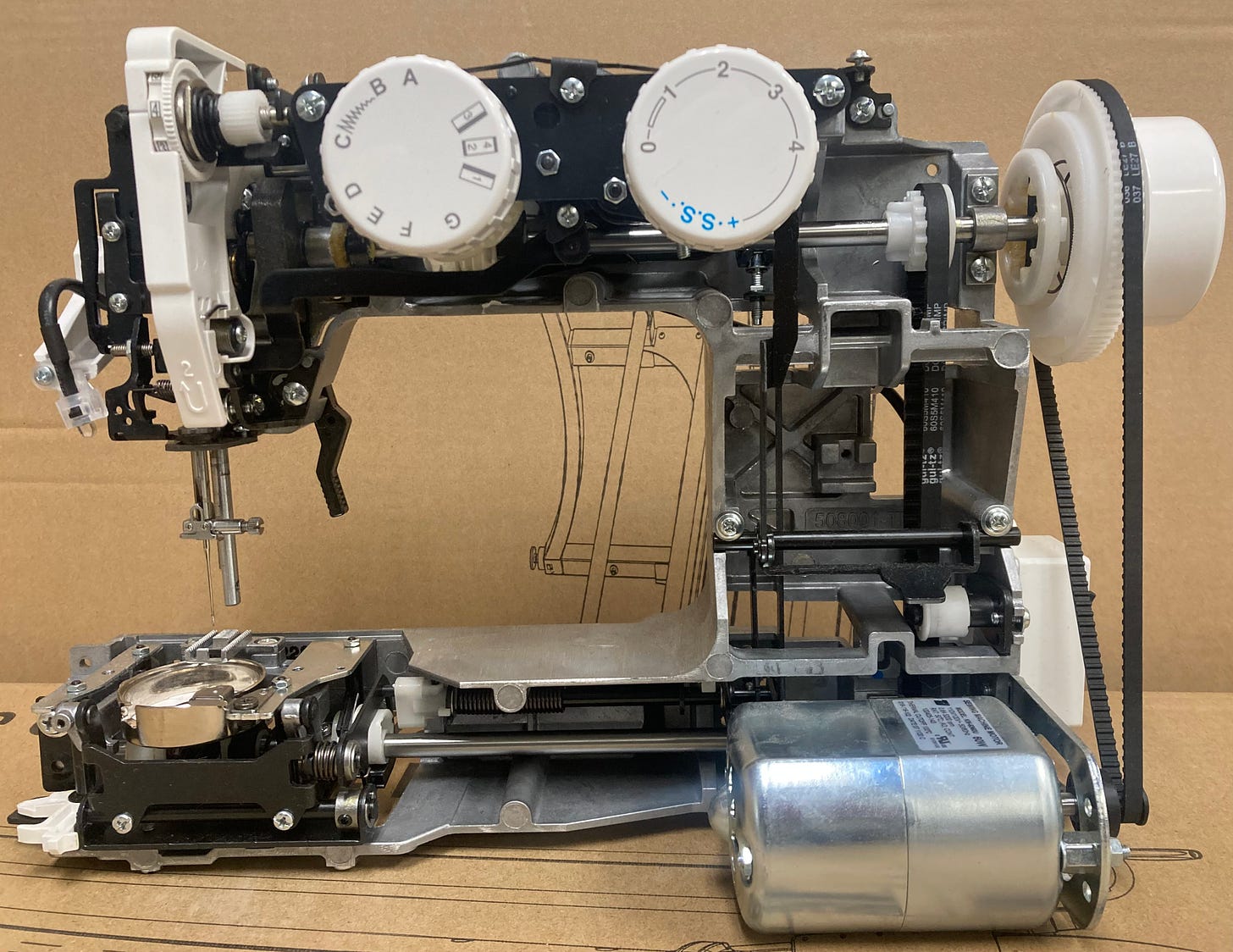

Anyone who has read our technical articles on sewing machines already knows that like a high quality home, everything starts with a good foundation (Tool vs Toy). On a sewing machine, this foundation is the frame or housing. The quality of the housing varies drastically, from machines that essentially have no housing at all to machines with extremely refined housing.

There are 3 basic housings:

(1) Molded Plastic

Although plastic is extremely economical and an excellent material for many items, it is a very poor material for a sewing machine housing because it is not rigid/stiff enough to achieve proper alignment for the hundreds of parts that must be attached to the frame. The flexing or warping of the plastic housing causes many issues and leads to a short lifespan and ultimate disposal into landfill. These machines are also very difficult to service as they are really not intended nor designed to be serviced. Just throw it out and get another

Because of their low cost, these are by far the most produced and purchased sewing machines. Despite the 4.5 star reviews on Amazon and the very false claim of being “Heavy Duty” I find these machines to be a poor choice if you want good performance, longevity, and most importantly FUN . Don’t settle for a toy instead of a tool. You don’t have to pay a lot for a real sewing machine.

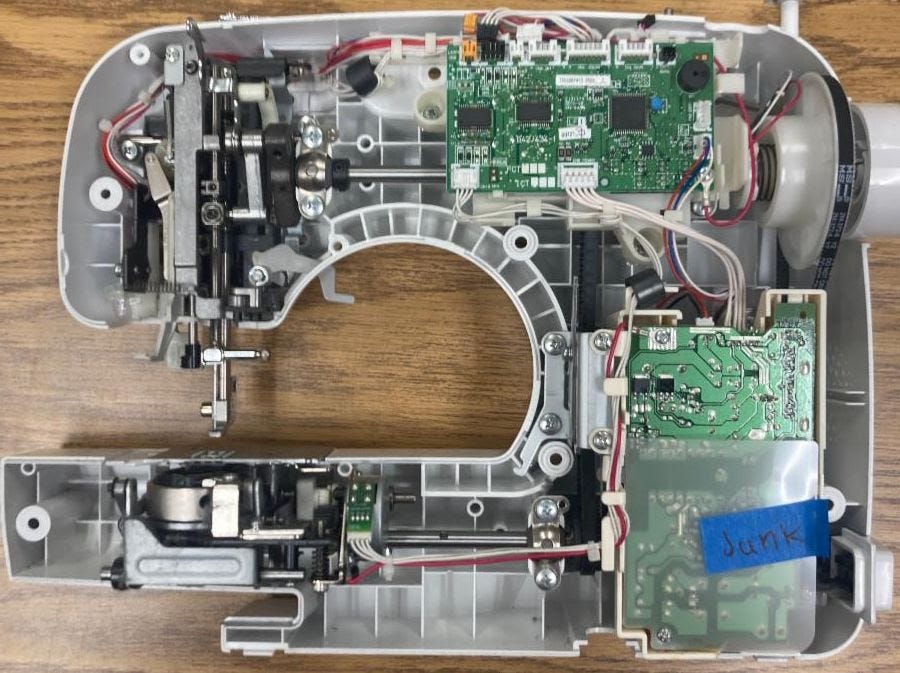

(2) Internal Cast Metal Alloy

Almost all higher quality sewing machines use this approach. However, the quality control, design and execution of this all important first step to building a quality sewing machine can vary. A well executed metal housing first and foremost aligns the top and bottom main shafts so that they turn freely and frictionless in their bushings and/or bearings. Alignment is key to the longevity of friction bearing components and the motors that drive them. The minimum requirement of any machine we sell is to have a high quality internal metal housing. Even our $249 machine has an outstanding foundation.

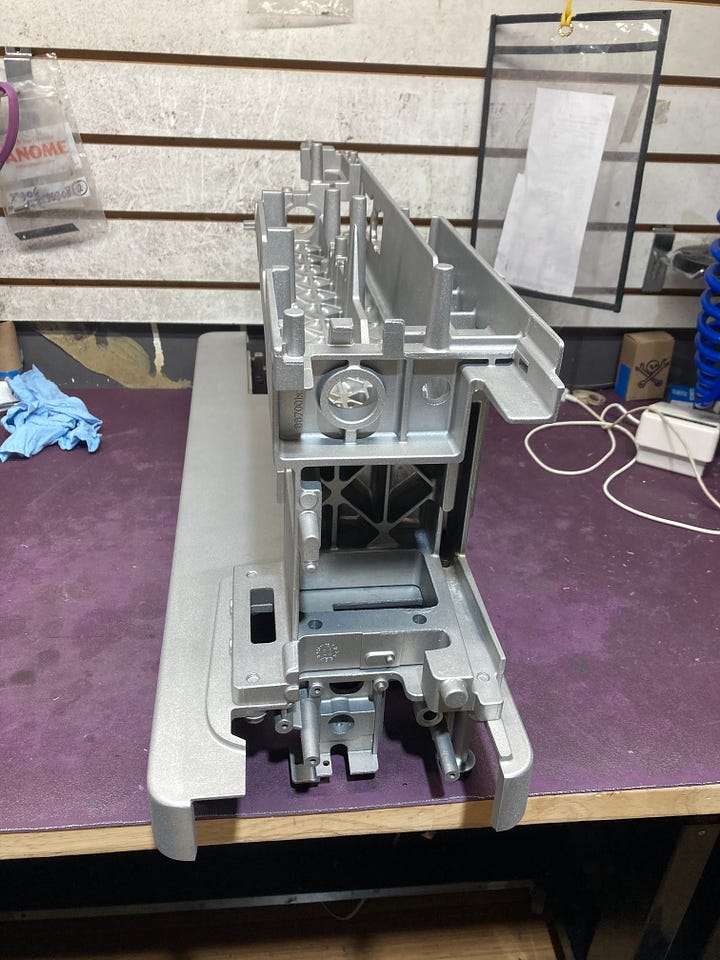

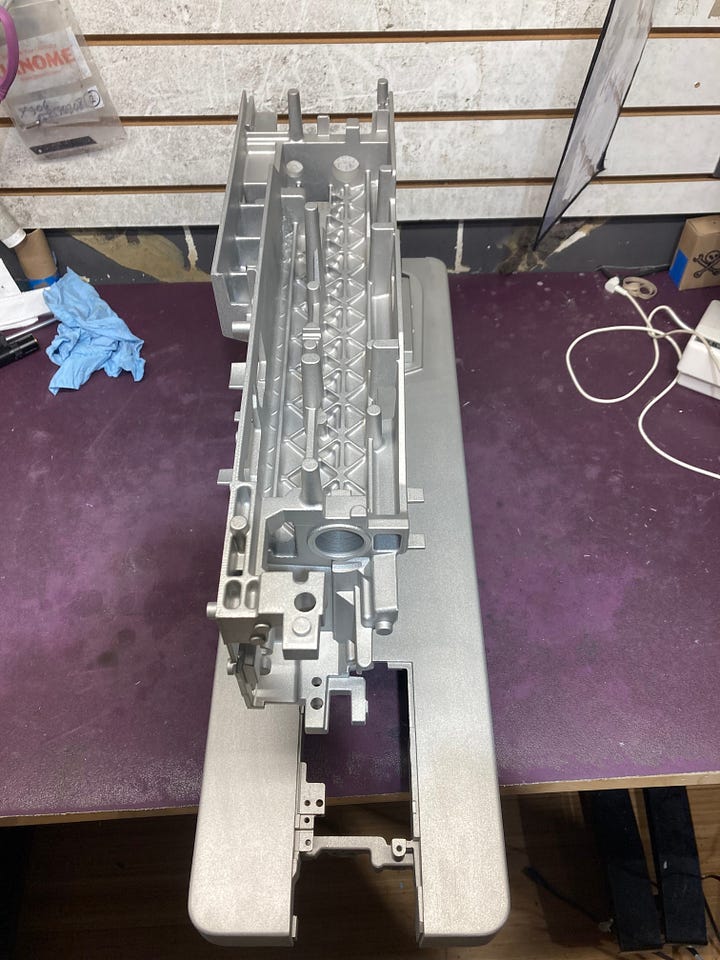

(3) External Powder Coated Metal Alloy Frame

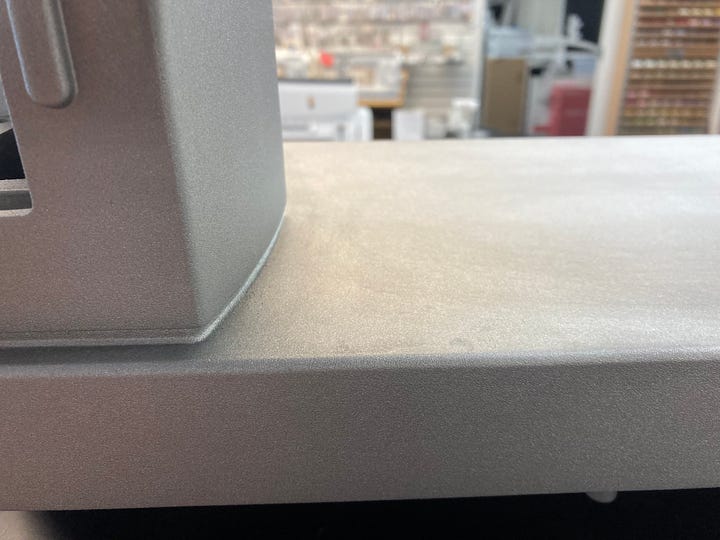

This housing is by far the most expensive to produce because unlike the internal metal housing which is unfinished and unpainted after it is removed from its mold, this casting is exposed to all to see, touch, and be judged.

Prior to powder coating, the cast alloy must be sanded perfectly smooth getting all of the seams and imperfections removed.

Powder coating is a process used instead of painting. Dry polymer powder that is positively electrically charged (approx 50,000 Volts) is sprayed onto the sewing machine housing that is grounded via wire. The charged powder adheres to the housing very evenly and smooth. The casting is then baked in an oven creating a very hard, thick smooth glossy finish. The advantage to paint is that powder coating can be applied thick without creating drip marks and imperfections. It is harder than paint, very resistant to chipping, fading, and scratching. The perfect durable finish for the bed of a sewing machine. Unlike the internal casting which requires plastic covers over the unfinished casting, the external casting is often seamless, thicker and with the powder coating creates an extremely quiet sound dampened sewing machine.

Conclusion

The benefits of powder coating is not why you should buy a sewing machine, but what really matters is the company willing to take the costly extra steps to make a stunningly beautiful product that is built to last 20-25 years even with heavy use. Janome is a serious sewing machine company that is driven by design engineers, not by the marketing dept (in fact, their marketing is not very good). This is why I rank the Janome Continental Series M6, M7, M8 and flagship M17 the finest sewing machines in the world. In addition to the seamless powder coated housing these models have other best-in-class features:

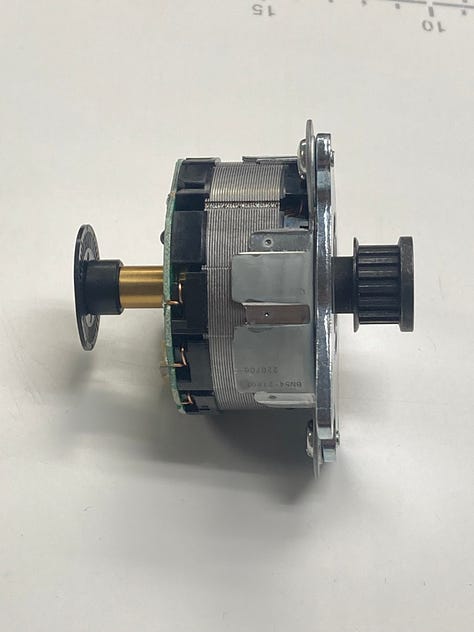

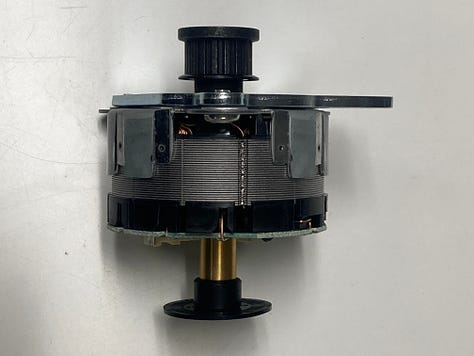

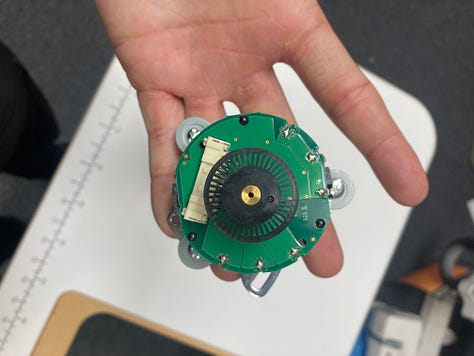

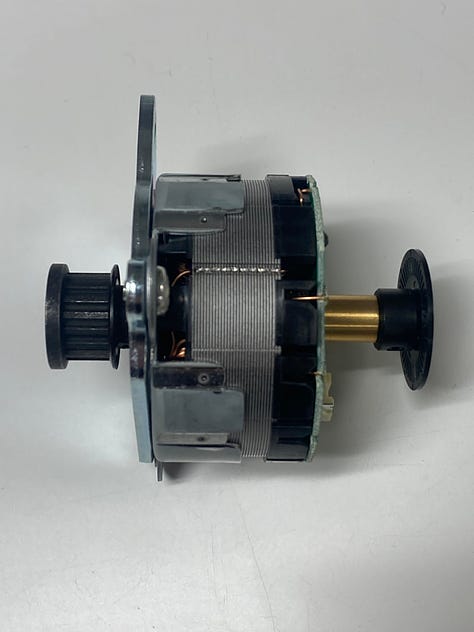

Motor

Janome Continental Series is the only home sewing machine with a brushless servo motor. Most powerful and longest lasting type of motor.

Bearings

Continental series uses sealed ball bearings instead of brass bushings on its main shafts. Janome also utilizes sealed ball bearings on some of its other models including the Skyline series, HD9, 6700P and 9400 series.

Needle Plate System

The correct needle plate is essential for performance. The Continental series gives you multiple needle plates that can be easily installed with the push of a button No Tools!

ASR Stitch Regulation

The M8 and M17 come with ASR (Accurate Stitch Regulation). This stitch regulator system uses infrared instead of laser, and is the best system available for uniform stitch length during FMQ (free motion quilting).

Stitch Regulators, Explained

Accuflex Plus Dual feed System

This feature transports fabric from the top and bottom to prevent ply shifting. It even has differential feed which can adjust the ratio from 1 to 1 to something other than 1 to1 to compensate for different fabric characteristics. Smooth pucker free seams is the end result.

All About Walking Feet

Additional Notes:

Design Awards:

M17 - 2023 iF Innovative Design award

M7 - 2020 Red Dot Design award

6700P - 2017 IDEA International Design Excellence Award

Current makes and models that I know of that are powder coated:

Janome M17, M8, M7, M6, 6700P, HD3000, HD9

Juki TL series (TL-2010, TL-18)

Brother PQ1600S

Baby Lock Accomplish 2

Thank you for reading.

Going forward, my dad has committed to contributing at least one article every month, so keep your eye out for more stuff from him.

Thank you. Very informative article. Keep them coming.

This is a very interesting article, thanks Dad! (Is it a coincidence that it came out on Father's Day?)

I just take issue with one thing, where he says to show a picture of the Singer Heavy Duty. I bought a Kenmore in 1975 and used it until 2019. Like an idiot, I gave it away, thinking I needed a new machine. I bought a Singer "Heavy Duty" and was stunned at what a piece of junk it was. I started making a wool throw pillow but the HD threw up its hands in dismay, and I finished it on a friend's Featherweight.

I love it when your posts show the insides and construction details of machines.