There is very unique room inside The Sewing Machine Shop, tucked upstairs next to the repair department. You could scour the entire world and I doubt you’d find many like it. This room is known as The Boneyard, a mausoleum for dead sewing machines.

The Boneyard is full of old machines that are no longer in working condition. We hold onto them because many of the machine’s individual parts are still intact, even though the machine does not work as a whole. Why do we do this? Most of the time, a machine that ends up in The Boneyard is a machine that is no longer being manufactured, and a machine that’s no longer being manufactured is a machine whose parts are hard to come by. Even if the manufacturer is still in business, it is uncommon for them to continue making parts for machines that are 30+ years old, especially obscure parts.

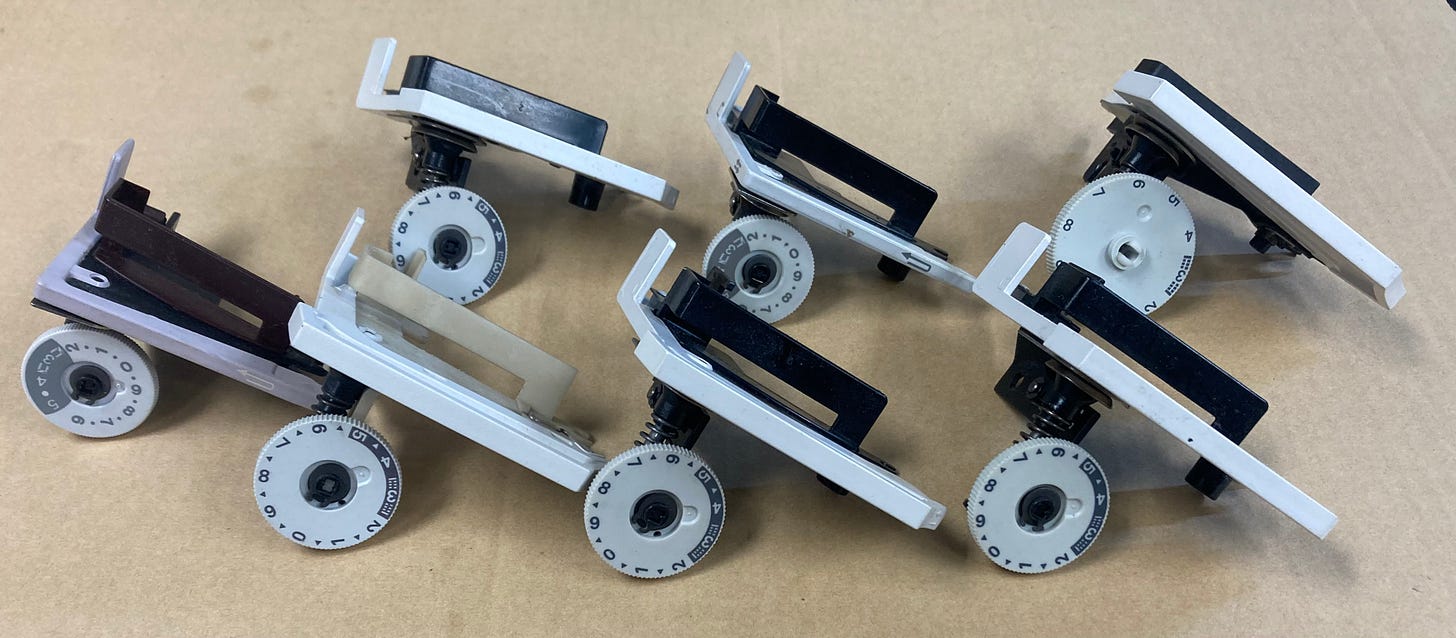

For example, I meet a lot of people who love their older German-made Pfaff machines (Creative 7550, 907 Hobbymatic, Tiptronic 2030, etc). However, in 2006 Pfaff was sold to Kohlberg & Company, an American private equity firm. While the Pfaff name remained, aspects of the manufacturing processes changed, and it became more difficult to acquire parts for those beloved older models. My father, a perfectionist at heart and a man who takes real pride in his work, began holding onto these older Pfaff machines. If somebody brought in a broken Pfaff that couldn’t be fixed, he’d give them a bit of trade-in value for the broken machine and store it in The Boneyard. Eventually the day comes when someone brings in that same model Pfaff with a problem and they really want it fixed. Perhaps the tension assembly is broken, and Pfaff doesn’t manufacture the tension assembly for their machine anymore. Fortunately for the Pfaff owner, The Boneyard exists. Inside The Boneyard is a bag full of older Pfaff tension assemblies:

And bobbin cases…

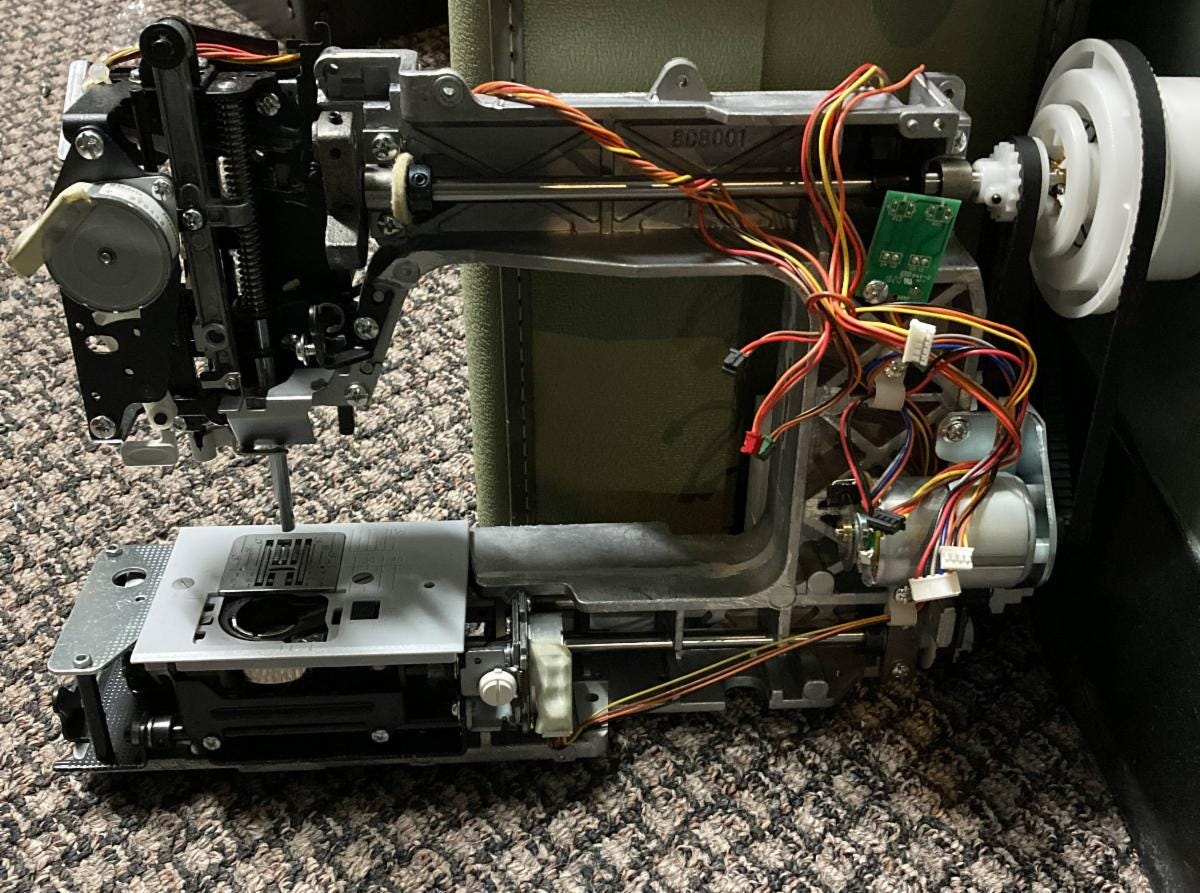

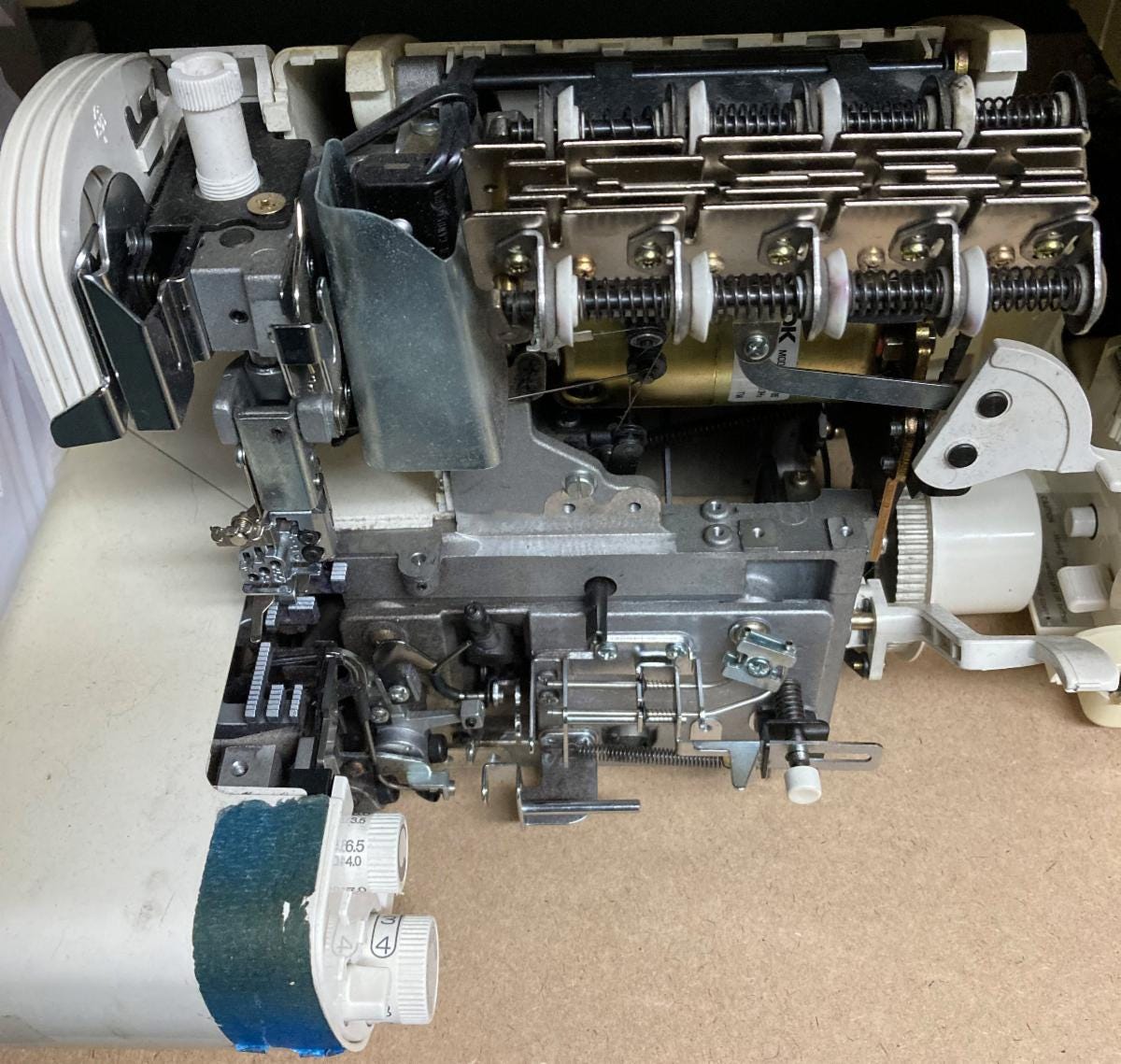

Hook assemblies…

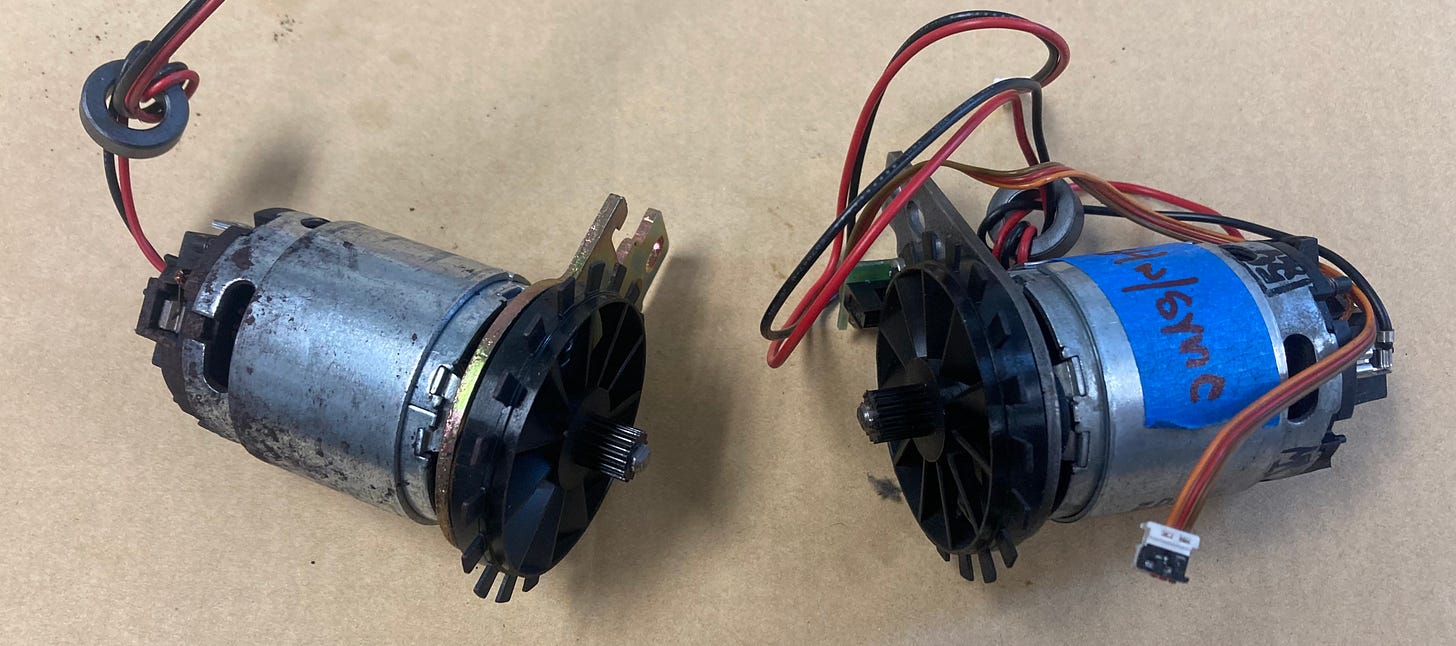

Motors…

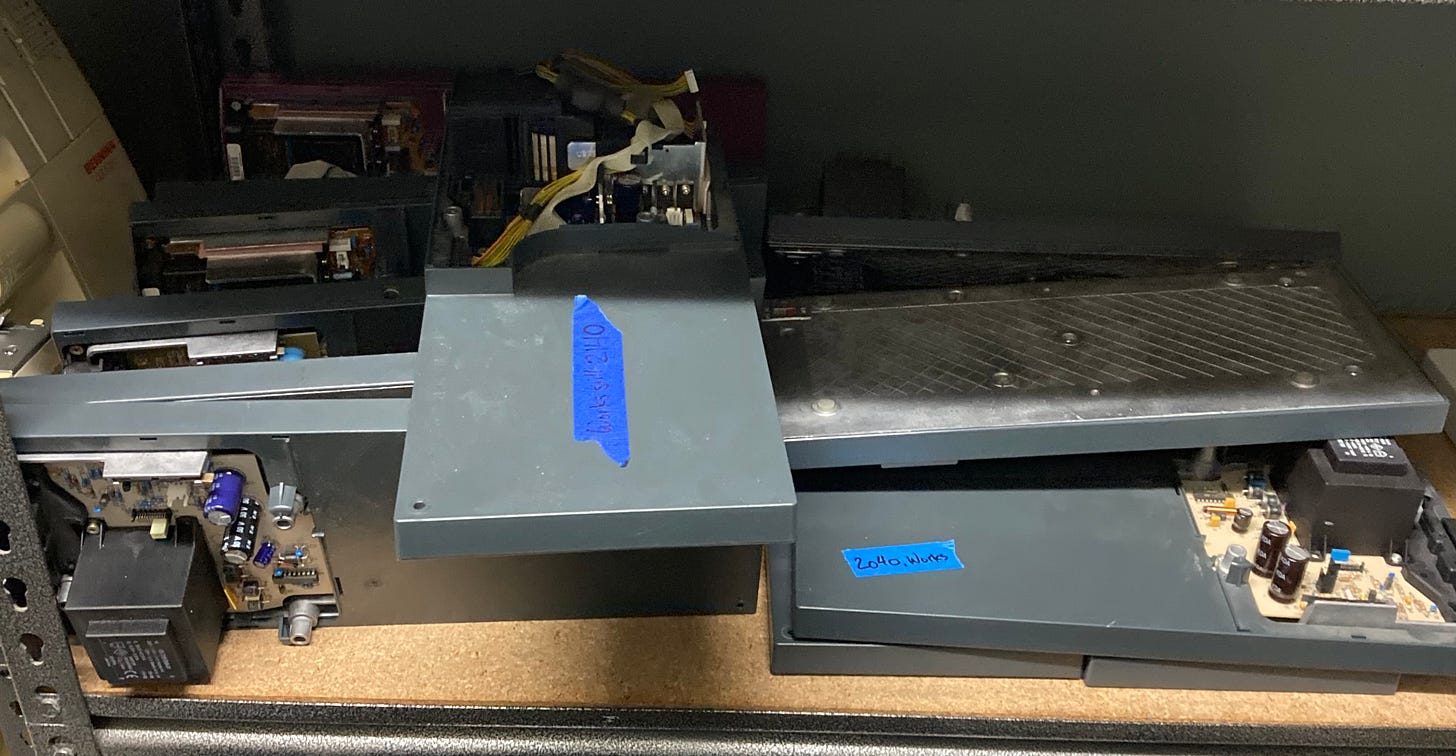

Power boards…

You get the picture.

The following is a true story that serves as a perfect example of why we maintain The Boneyard. Not long ago, a woman came into our store with an old Elna SU sewing machine that was manufactured in the 1950's. Unfortunately, the machine's motor had died and could not be repaired. Being 50+ years old, the original motor for the Elna SU is no longer being manufactured. The owner of the machine was in a tough spot. She absolutely loved her machine and did not want to get a new one.

My father (Dan) dug through The Boneyard and found an Elna SU. The Boneyard Elna SU was inoperable because of a worn out needle bar assembly, but the motor was still in working condition. He performed sewing machine surgery, removed the bad motor from the customer's Elna and replaced it with the good motor he cannibalized from The Boneyard's Elna. While operating on her machine, he also noticed a few cracked gears that could potentially cause problems in the near future. The same gears on The Boneyard's Elna were not cracked, so Dan swapped them out as well. In the end, he essentially took two dead machines, and made one good working machine. I joke sometimes that he is the Dr. Frankenstein of sewing machine repair.

These Frankenstein repairs are not uncommon. In fact, there are many such stories as the one I just told:

Above: my Uncle Marty (left) & Dad (right) perform emergency surgery on a Pfaff 1222.

Below, Marty guides my Dad and our other technician (Danny) on a complicated Bernina 1530 gear replacement surgery.

Frankenstein repairs are cool, and I love that fact that our repair department is capable of such feats, but they do come with some implicit risk.

When we cannibalize parts off of a machine from The Boneyard, it’s important to note that those parts are not new. They are coming from an old machine, a machine that was used for 20/30/40+ years. If a particular machine is of the age where the power supply is going bad, the power supply we have in The Boneyard is susceptible to the same problem. In other words, The Boneyard is not a permanent solution. If you are looking for a machine that will last, my opinion is that paying for a Frankenstein repair on your old machine is not the way to go. Unless there is sentimental value, I suggest you save that money and invest it in a new machine.

Now, I know what some of you will say, especially lovers of vintage machines: “they don’t make machines like they used to.”

I understand where you are coming from, but it is not necessarily true. I will address that sentiment in a future newsletter.

Thank you for reading.

-Cale

For your info, my opinion, Ray White is a good resource for early ELNA machines. He has his own boneyard, refurbishes and sells many ELNA parts exclusively. I really like that you and your team can work on older machines.

I think of this "Bone Yard" as a National/International TREASURE! 2 dysfunctionals end up 'creating'/giving 'life' to a wonderful new 'life'!

Where can we access info on this place? I do travel and would love to know! (I did google it and didn't come up with anything...)