Troubleshooting 101: Change the Needle

How a bent needle affects needle-hook clearance and causes skipped stitches

A fairly common occurrence at The Sewing Machine Shop is that someone comes in with their machine that is skipping stitches, but when I power up the machine and sew on it, there are no skipped stitches for me.

Some have said there must be some sort of magic that occurs by walking through our door. Others say that I have the Midas Touch for sewing machines.

Neither is true.

There is no magic at play, but there is a secret: needle-hook clearance is a leading cause of skipped stitches, and a slightly bent needle can throw the needle-hook clearance out of whack.

With that being the case, if you get skipped stitches and want to troubleshoot your machine at home instead of bringing it to a technician, the first step is to insert a new needle.

Skipped Stitches

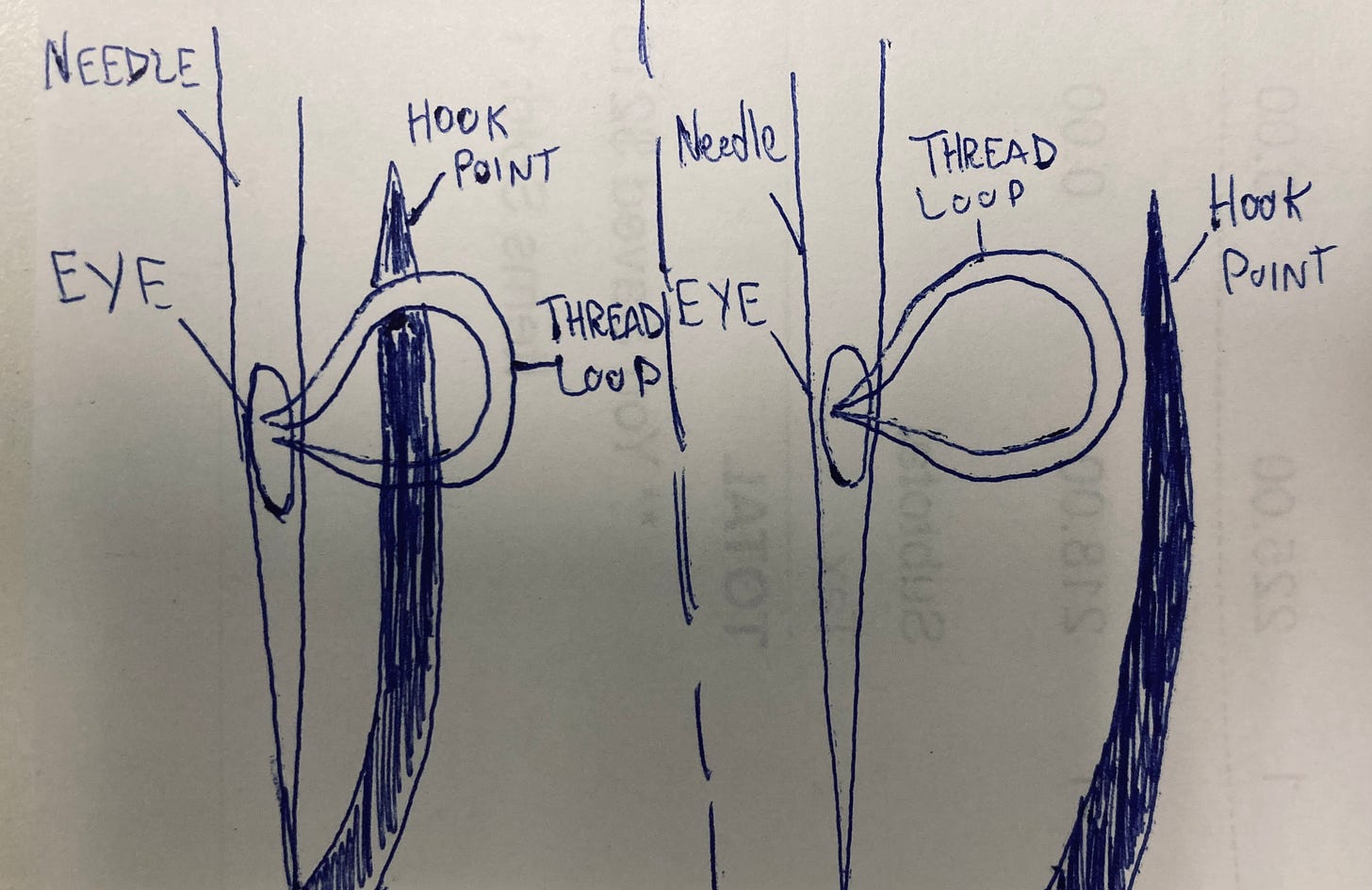

Simply put, skipped stitches occur when the hook-point fails to pass through the thread loop that forms at the needle-eye. To get a better visual, please watch the beautiful skipped-stitches animation below:

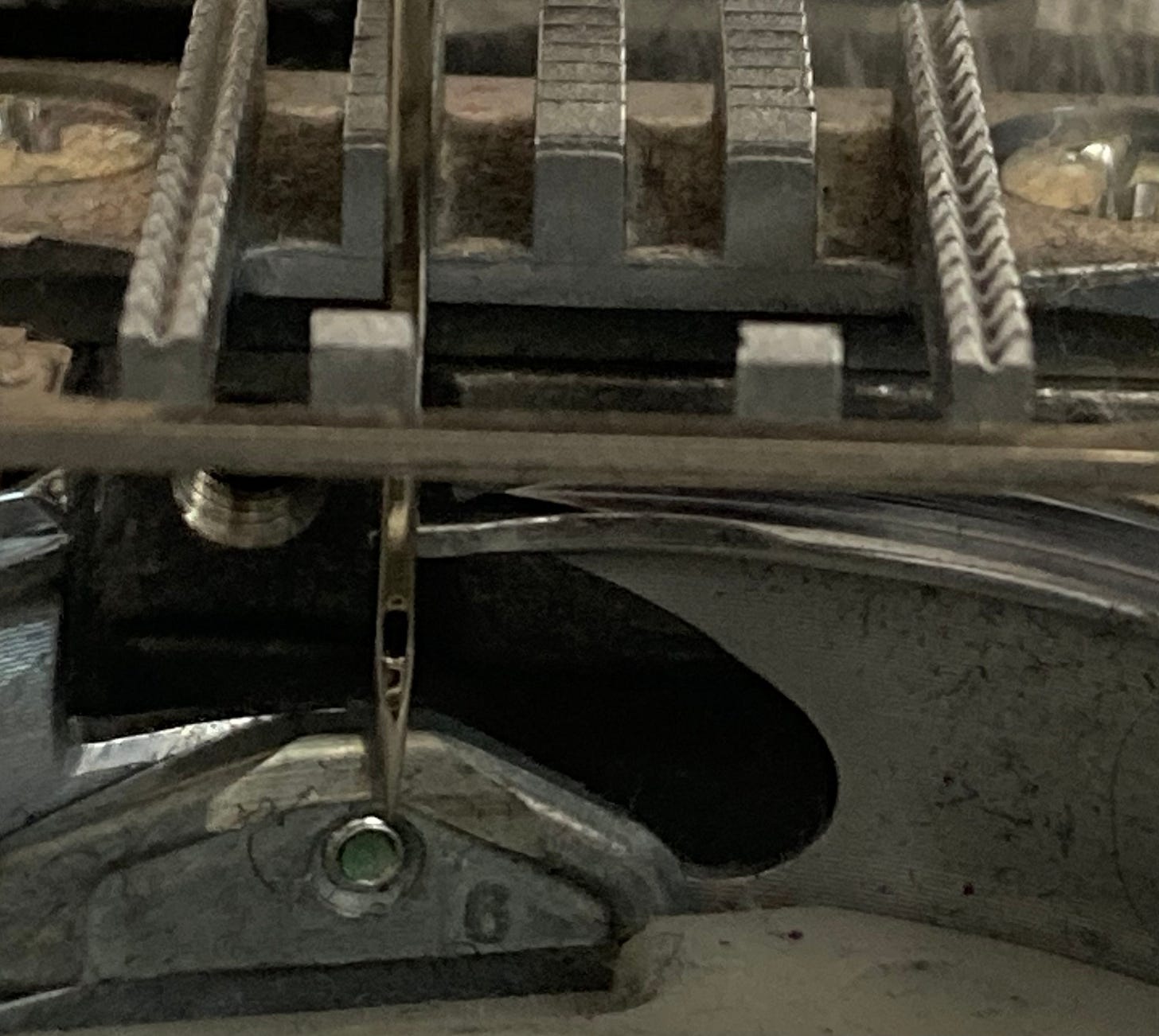

In order for a sewing machine to make a stitch, the hook must pass just above the eye of the needle when the needle rises a few millimeters above its bottommost position. The hook point must pass above the eye because that is where the needle thread loop is formed, and the hook point must pass through that loop in order to make a stitch. If the hook-point fails to pass through that thread loop, you are guaranteed to get skipped stitches.

If the needle-hook timing on a machine is off, the hook may miss that loop because it passes below the needle eye (advanced needle-hook timing). Or, inversely, it can also miss the loop if it passes excessively high above the needle eye (retarded needle-hook timing).

However, it is more common that a machine skips stitches due to poor needle-hook clearance than poor needle-hook timing. Why? Because bent needles are extremely commonplace, and bent needles mimic poor needle-hook clearance.

The needle-hook timing could be perfect (as seen in the photo above), but the hook point could still be missing the thread loop that forms at the eye of the needle.

How?

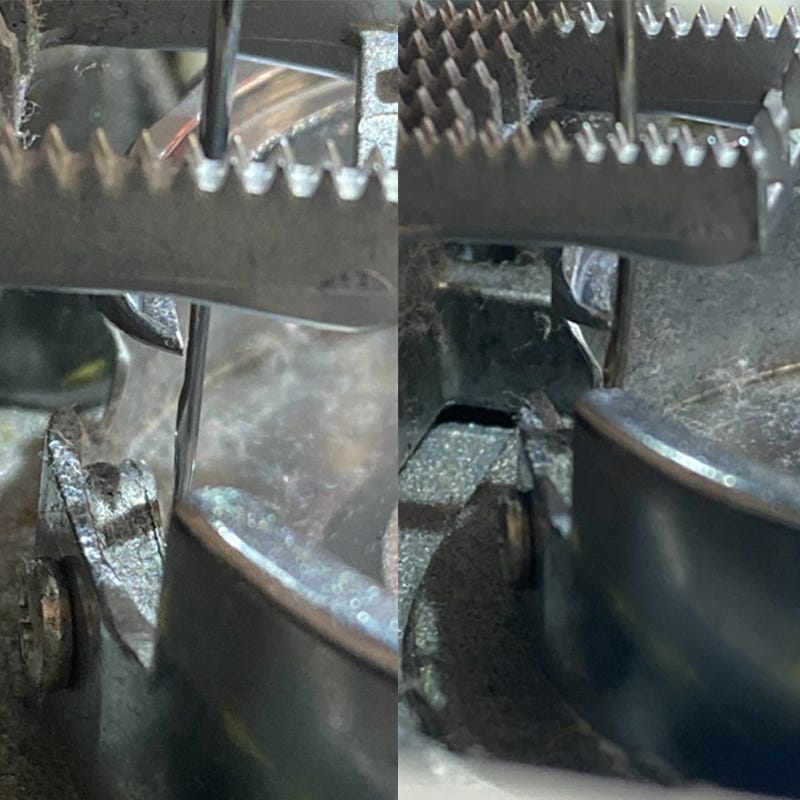

Because when the hook passes behind the needle, the hook must pass within a specific distance range from the back of the needle in order to catch the thread loop. You don’t want the hook to be so close that it touches the needle, but you don’t want it to be so far away that it passes behind the thread loop instead of passing through.

We need the hook to pass through the loop, but the loop only extends so far behind the needle. The hook cannot be positioned excessively far in distance from the back of the needle, or else it will pass behind the thread loop instead of passing through the loop.

Needle-hook clearance is a critical setting that can cause skipped stitches if too tight or excessive in distance. If you are getting skipped stitches because needle-hook clearance is truly out of whack, a trained sewing machine technician should be able to fix the problem for you.

However, a bent needle can often mimic needle-hook clearance being out of whack. Therefore, if you get skipped stitches and want to troubleshoot your machine without bringing it to a technician, I implore you to first insert a new needle and see if it fixes the problem. And when I say new, I mean fresh out of the box. I don’t care if the needle currently in the machine has only been used for 1 hour, 1 minute, or 1 second— in order to confidently troubleshoot skipped stitches, I need a needle that I know has truly never been used before.

Thank you for reading. I hope you found this article helpful.

The stitch-making process is complex and there is not a lot of room for error. Therefore, things that may not seem like such a big deal, such as a slightly bent needle, can actually cause massive problems.

And, as it so happens, a slightly bent needle can also mimic a needle thread being bent or broken. If your needle threader isn’t working, troubleshooting 101 is to insert a new needle. I go into further detail as to why this is the case in two previous articles I wrote:

Also, if you want to learn more about needles and why they are so important, I recommend you read:

Thank you for reading,

-Cale

Good to know! Now if I can only figure out the buttonhole foot and sensor that comes with my Pfaff 7570...😬