Underrated Sewing Machine Features That I Value

I like them because you love them (even if you don't know it)

A big part of my job at my father’s shop is selling sewing machines, and I’ve become pretty darn good at it because I’ve been able to recognize what features sewists like, even if the sewist doesn’t know it themselves. In today’s edition of The Sewing Machine Newsletter I am going to share a handful of sewing machine features that I like and that sewists love. I consider these to be high customer satisfaction features — the more of these features that somebody has on their machine, the more they end up loving their machine.

Throat Space

Throat space is the open window of space to the right of the needle where a sewist would place the fabric they are sewing, whether it be a quilt, garment, or anything else.

Modern machines for less than $500 offer about 5-6 inches of throat space. At the $800 price point you start seeing machines with 8.5 inches of throat space. At $2,500-3,500 you’ll see machine with 10-11.5 inches of throat space, and at $4,000+ you now see machines with 13.5" inch throats.

From my experience, the larger the machine’s throat space, the happier the sewist. Having more throat space gives you more room to operate, whether you are sewing a jacket or a queen-sized quilt. When sewing larger swathes of fabric, you need not roll the fabric up as much to fit it in there. This makes a world of difference in regards to how comfortable you are when sewing/quilting and how easy it is to maneuver fabric. It’s nice to not feel cramped and claustrophobic and restricted while sewing, plain and simple.

In addition, larger throat space often coincides with better lighting. Most machines with 8.5”+ throat space will have lights in the top of throat itself, which is a definite positive. The larger throat gives you increased visibility in terms of space, but it also gives you increased visibility with better lighting.

Fortunately, it’s never been less expensive to get a machine with lots of throat space. For years, the Janome Continental series had the most throat space in the world at 13.5 inches (M7, M8, M17). However, Bernina recently released the new B990 with 14 inches of throat space, and both Brother and Baby Lock will be releasing a new top-of-the-line machine later this year with a 14 inch throat. In turn, Janome has responded not by making a machine with a 15 inch throat, but instead releasing the Continental M6 with 13.5” throat at $3,999, which is $1,000 less than the Continental M7. That is a brand new sewing machine with 13.5 inches of throat space for under $4,000. Incredible.

I will also note here that the new Janome MC9410 with 11.25” throat is around $3,000. The price of a pre-owned M7 (13.5”) should go down to about $3,000-3,500, while pre-owned Janome MC8900/8200/7700 (11.25” throat) should be somewhere between $1,200-$2,000. And, as many people trade in their old 7-series Bernina machines (10” throat) for the new B990, you should be able to get pre-owned B740’s for ~$2,500-3,000 and pre-owned B710’s and B750’s for ~$2,000-2,500 depending on the condition and accessories that comes with it.

Heavy Touch & Feel

Some of the most beloved sewing machines of all time are vintage Berninas (1970s, 80’s, 90s), vintage Pfaff (80’s, 90s), and vintage Singers like the 301a. These machines do not have modern features like a truly automatic needle threader or auto thread trimming, but people still love them. Why? I think a big part of it is the heavy touch and feel that these machine offer to the user as they sew.

I often hear people complain about the touch and feel of modern machines, citing that “they feel like they are made of plastic.” This is an unfortunate misconception, but certainly understandable. After all, the most popular machines sold in places like Amazon and Walmart actually are made of plastic. However, there are plenty of modern machines built with metal housing, as my father explains in the video below:

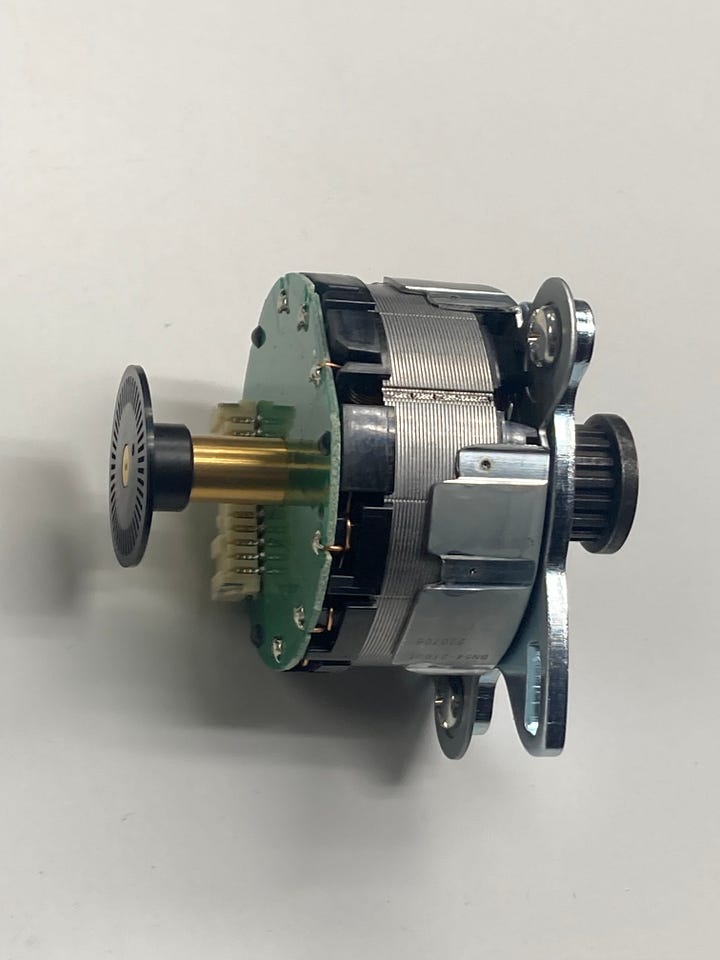

The housing of the machine, in conjunction with the quality of the hook system, internal components, and motor, are the main factors of a machine’s touch and feel. The more robust the metal housing of a machine, the heavier the touch and feel. The better the motor, the more robust the touch and feel. That is why industrial machines feel so sturdy— a machine completely made of heavy metal, housing accompanied by an industrial-grade motor. It is why the Janome Continental series has such a heavy touch and feel: massive metal housing with a brushless servo motor.

Modern Bernina machines also have a heavy touch and feel. They are all designed with full metal housing, plus the beautiful steel B9 hook system gives these machines an old-world feel that is special.

The best way to tell if you like the touch and feel is to sew on the machine yourself. That’s why it’s great to have a local dealer with machines on the saleroom floor that you can sew on before deciding on what to purchase.

Pivot (Electric Lift)

The pivot feature essentially acts as automatic knee lift.

A traditional knee lift is a mechanism that attaches to your machine that allows you to raise/lower the presser foot with your knee, rather than raising/lowering the presser foot with your hand. This allows the sewist to keep their hands on the fabric at all times, which can be helpful when sewing a quilt or garment where both hands are needed.

The pivot feature is helpful for the same reason. With pivot, when you take your foot off the foot pedal and stop sewing, the machine will stop with the needle in the down position. At the same time, the presser foot will raise automatically and hover above the fabric, and will do so until you choose to start sewing again. To see the hover feature in action, take a look at the video below:

From personal experience, I know that sewists who have a machine equipped with the pivot feature absolutely love it. Because the presser foot raises immediately at our whim, we can quickly check to see our seam allowance whenever we want. If the seam is on target and looking good, then we can keep on sewing. However, if it is off target, we can make any minor adjustments needed. Because we don't have to lift the presser foot lever manually, we can keep our hands on the fabric, which makes re-adjusting and re-aligning fabric easier than ever before. Also, if we are piecing the top of a quilt, you can use the hover feature to quickly pivot at corners of the quilt block.

It may seem luxurious, but it truly makes the sewing experience easier and more fun. It’s one of those feature where, once you experience it first hand, it’s hard to go back to a machine that doesn’t have it. Less Fussy = More Fun.

Thank you for reading.

A couple other sewing machine features I love are the automatic needle threader and integrated dual feed (integrated walking foot). I’ve written about these features before and linked you to those articles below:

I have a Singer XL1, which was made by Juki in the early 90s. I had to have the motherboard replaced in the late 90s - I lived at the time in Western Australia, which (at least then) ran the power grid at 240-250, unlike the rest of Australia which maxed at 240 (the grids aren't connected). I haven't had any issues since.

My favourite features of the machine? I'd never used a needle threader before, and that alone saved so much time. I was much more productive.

Another feature was the wide foot - the standard needle position is on the left, and the distance between the needle and the right hand side of the standard foot is 1.5cm, which is the standard seam allowance for the large commercial pattern companies. Not only does it securely hold the fabric, but it is so easy to maintain the correct seam allowance.

Finally, the pressure foot lever is at the front of the machine - easier to access - and if you press it down at the end of a seam it pushes both threads to the wrong side and cuts them off, leaving a tiny tail.

Every so often I consider buying a new machine, but I would lose at least one feature that I've grown to love, so I'm still happily sewing on my XL1.

I just found your stack. I am so impressed. I notice Husqvarna Viking is totally missing from your lists. Reason? I love HUSQVARNA machines. The advanced features are wonderful, but the basics are so well done. One of the best, no need to have a starting piece of fabric before stitching on the edge of the smallest piece of any fabric.

My biggest issue with them is the support. Stores are closing, are in terrible JoAnn locations, poorly staffed and workers that mostly only know how to sell product. Independents follow the same pattern with workers. So very SAD. I look forward to learning my machine fully with the posted videos, but having a human who knows the product, cares about the customer and offers training is still tops.

I once had a Viking dealer independent in Tacoma WA who was from South Africa and he and his wife were both involved, experts, kind, and supported us. I miss them!