Compacted Lint & Shredded Thread: 5 Key Areas of your Sewing Machine to Focus on Cleaning

Advice on how to maintain your own machine at home!

Greetings everybody,

When we consider the different things we can do to maintain our machine at home, a major point of focus ought to be cleaning out unwanted lint and shredded thread. Today I am going to focus on 5 areas on your machine succesptible to compacted lint and shredded thread that you can clean yourself.

I hope you find it helpful.

-Cale

First, Addressing The Canned Air Discourse…

Floating around the ether of the sewing machine world is the misconception that blowing out your machine with canned air is bad for the machine itself. I have heard people say that it can dislodge wires and mess up the electronics. They say it’s bad because it blows lint deeper into the machine. They claim it actually damages the machine.

This is simply not true.

Take it from me, my father, my uncle, the other techs who work with us— we use the power of air to clean lint out of the machines we service. Air clears out nooks and crannies you can’t see. It reaches places your lint brush could never reach. At our shop we use a super powerful air compressor to blow lint out of machines. For your home use, a can of compressed air will do just fine. Most lint will fly out of the machine and into your sewing room. Anything blown deeper into the machine will most likely float down to the bottom of your machine’s outer shell and out of harms way.

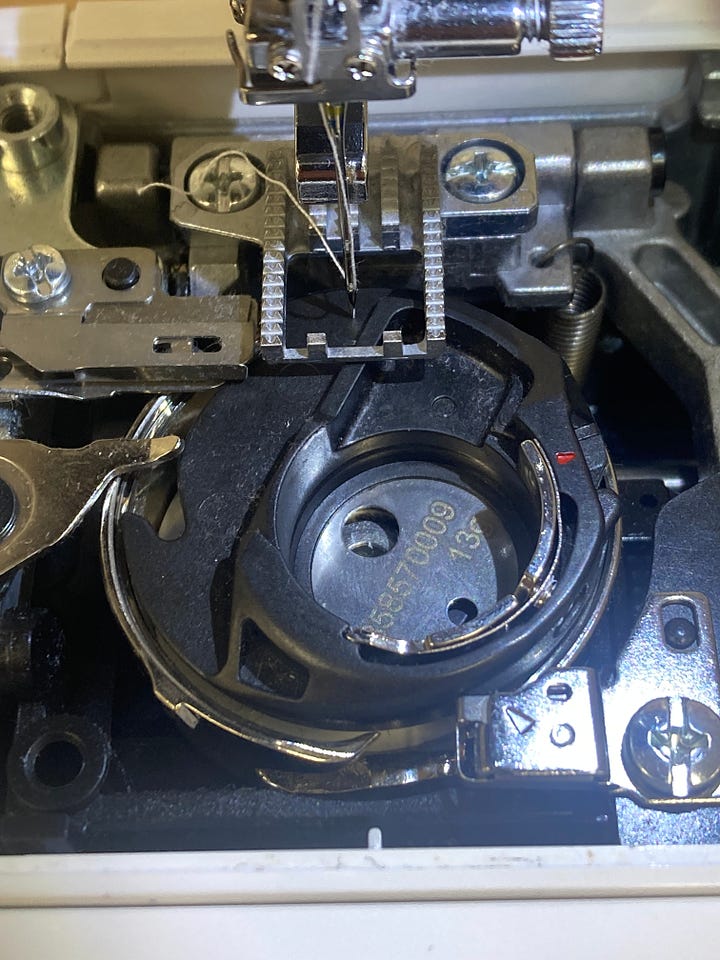

(1) Hook Mechanism

Whether you have a vertical front loading bobbin system (Bernina, vintage Pfaff) or a horizontal rotary hook drop-in bobbin system (Janome, Brother, Baby Lock), you will definitely find lint build up in your hook mechanism underneath the the bobbin case and hook mechanism.

It’s important to clean this area because lint buildup beneath the bobbin case can jar the bobbin case out of position. No matter your machine, if the bobbin case is jarred out of position, there’s a chance it will wander into the path of the needle. The needle will strike the bobbin case, damage the bobbin case, and potentially throw your machine out of time. It’s something you definitely want to avoid, and cleaning out that compacted lint is a way you can prevent it.

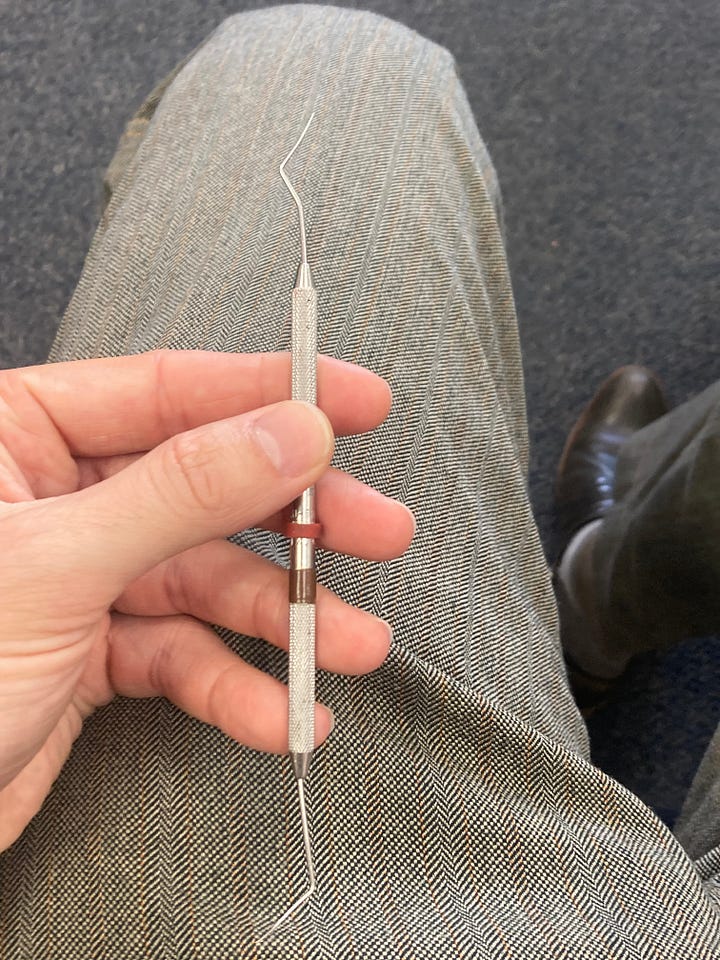

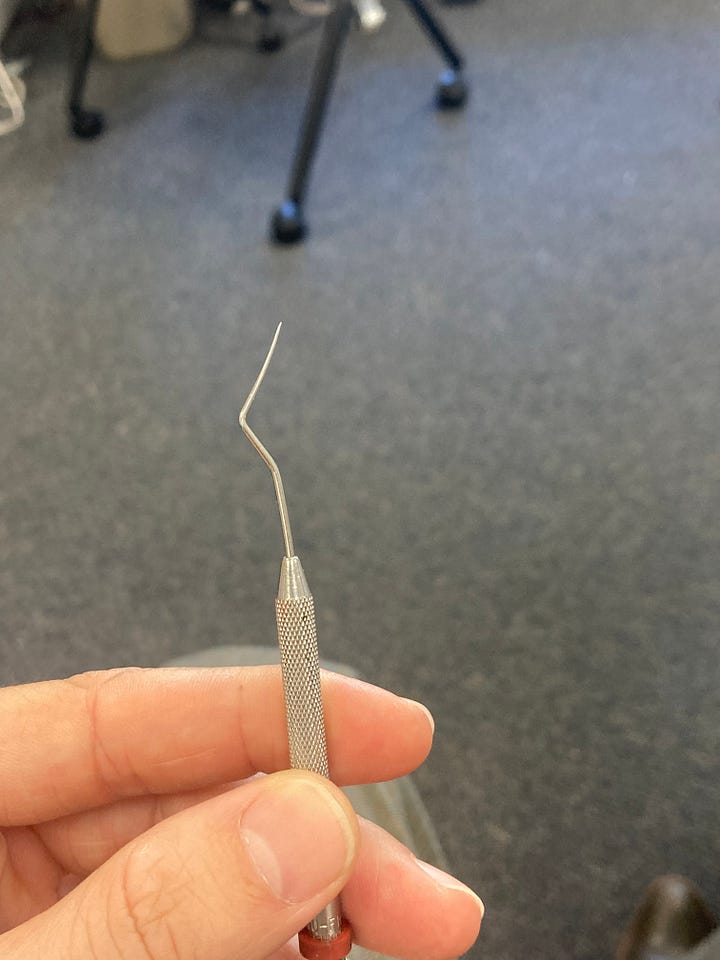

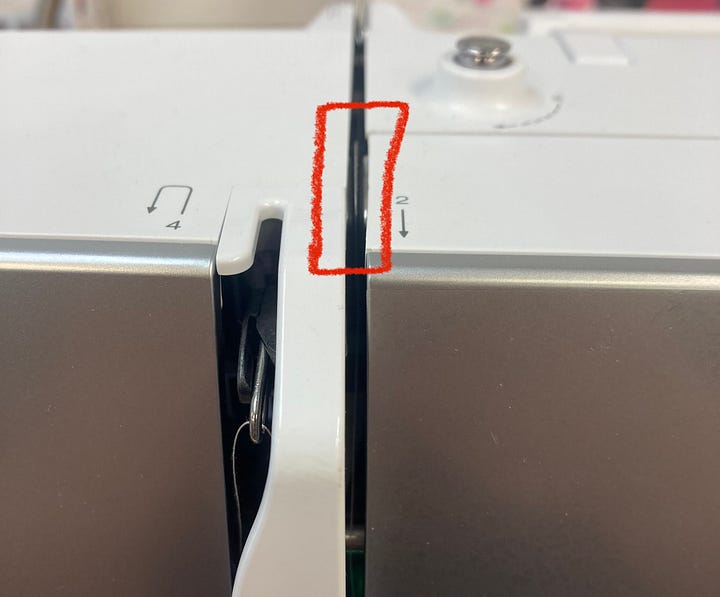

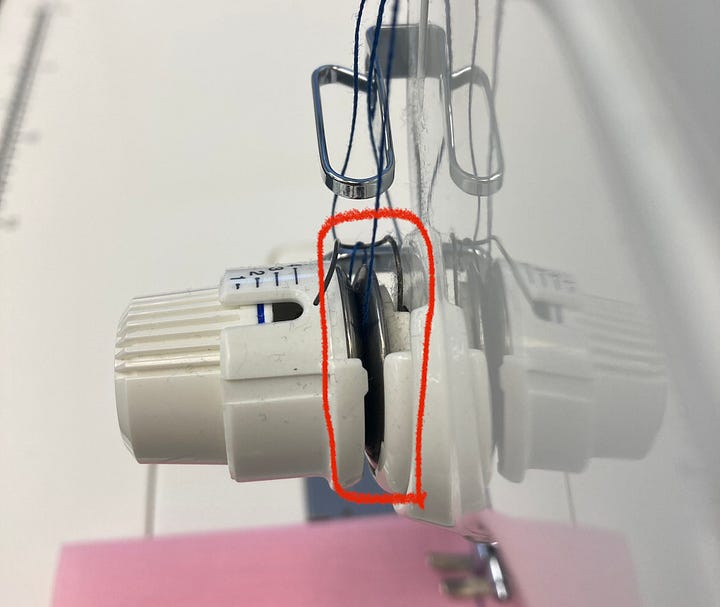

(2) Bobbin Case Tension Discs

A fairly common thing I see is someone who brings in their machine because they are getting small loops (a.k.a. eyelashes) on the top side of their fabric. These small loops indicate that the bobbin thread is not under tension, something our technicians refer to as zero tension condition. Often this is due to user error, when the sewist accidentally does not slide their bobbin thread between the bobbin case tension discs properly. However, many times they did thread the bobbin case correctly, and there is still a zero tension condition on the bobbin case. In that circumstance I take a close look between the bobbin case tension discs (thin silver discs circled in red in the photos below).

If compacted lint and thread gets stuck between those discs, the discs will not close properly. If the discs don’t close properly, then the bobbin thread will have zero tension and get sucked up to the top of the fabric, manifesting as small loops.

When cleaning your machine, blow some canned air between your bobbin case tension discs as a precautionary measure. If you ever get loops on the top side of your fabric and you have a zero tension condition, canned air may not be enough. Often the lint gets so compacted that I can’t see it with the naked eye. But, because of my experience and the experience of those who taught me, I know there is something stuck in there, even if I can’t see it. Fishing around with a pin or needle might be more effective. My favorite tool is actually a dental tool used to scrape plaque off teeth. The thin rigid pick does a great job digging out thread and lint from those tiny hard-to-reach tension discs.

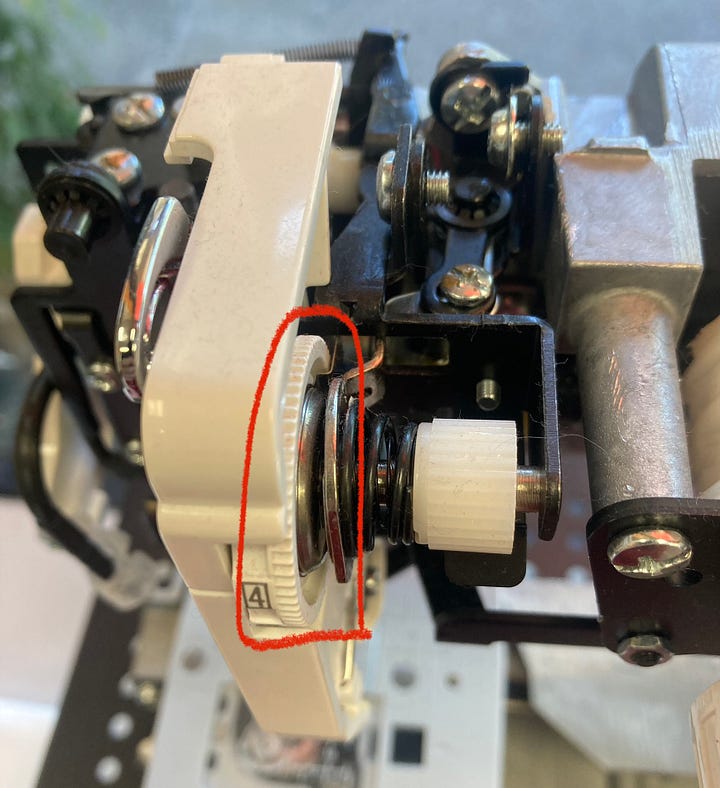

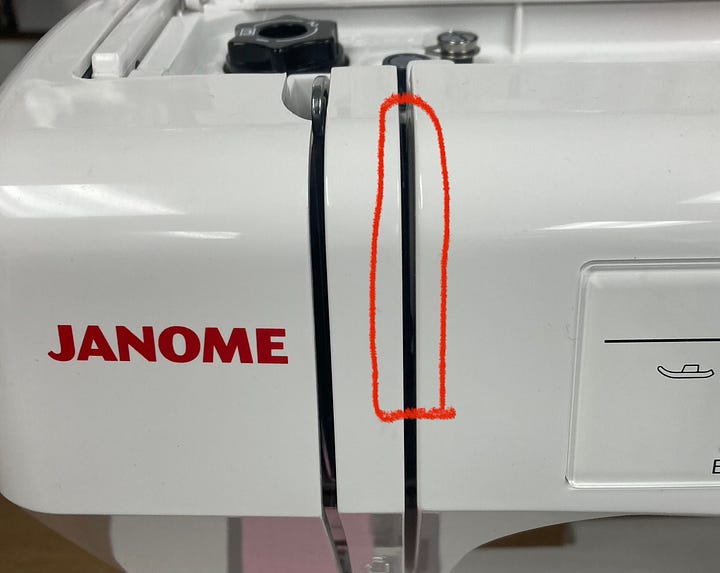

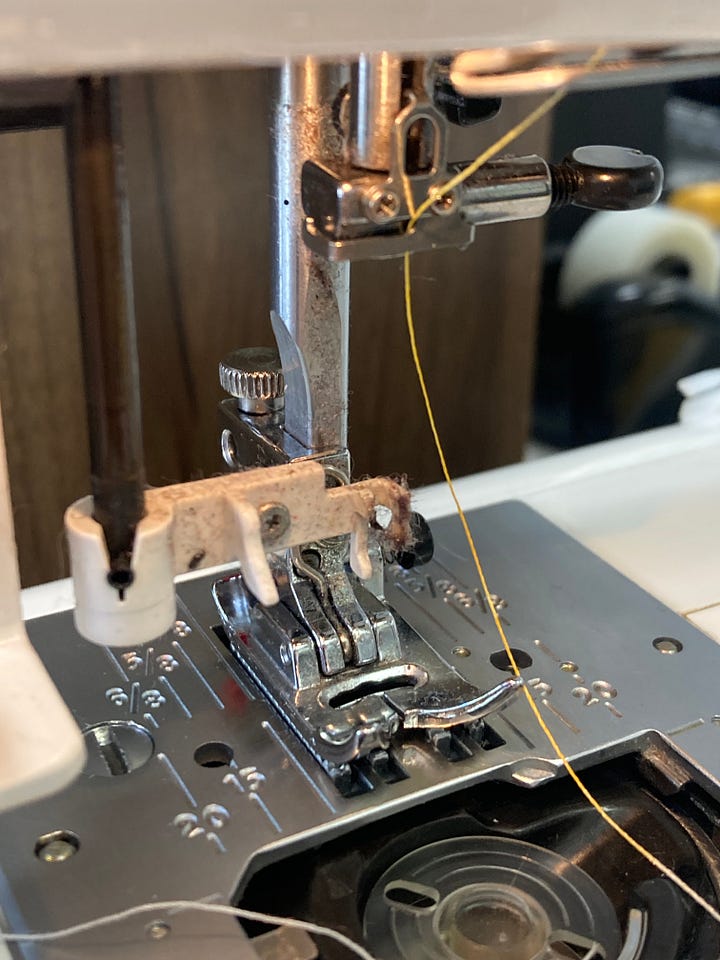

(3) Upper Tension Discs

Similar to the bobbin case tension discs, compacted lint/thread wedged between the machine’s upper tension discs may cause a zero tension condition with the top thread. Whereas zero tension condition in the bobbin case causes loops on the top side of the fabric, zero tension condition for the upper thread will result in loops (eyelashes) on the underside of the fabric.

Where are your upper tension discs?

When the presser foot is in the raised position, the tension discs are open. When the presser foot is lowered, the tension discs are closed. To clean out the upper tension discs, raise your presser foot to the up position. Then, with your canned air, blow out the space between your tension discs. Again, I promise that canned air cannot damage the machine

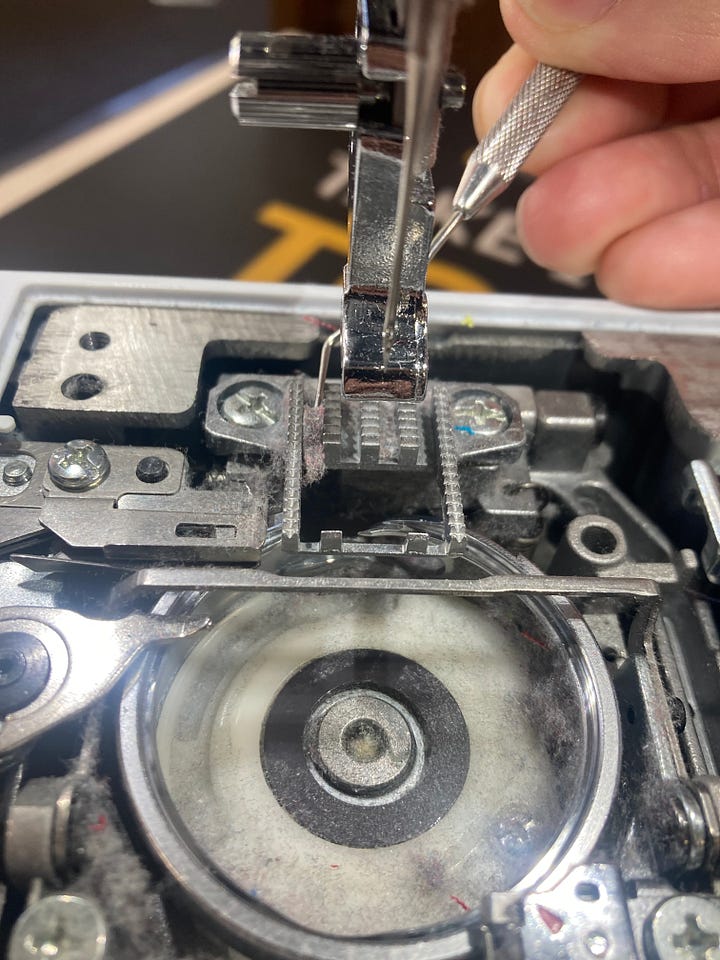

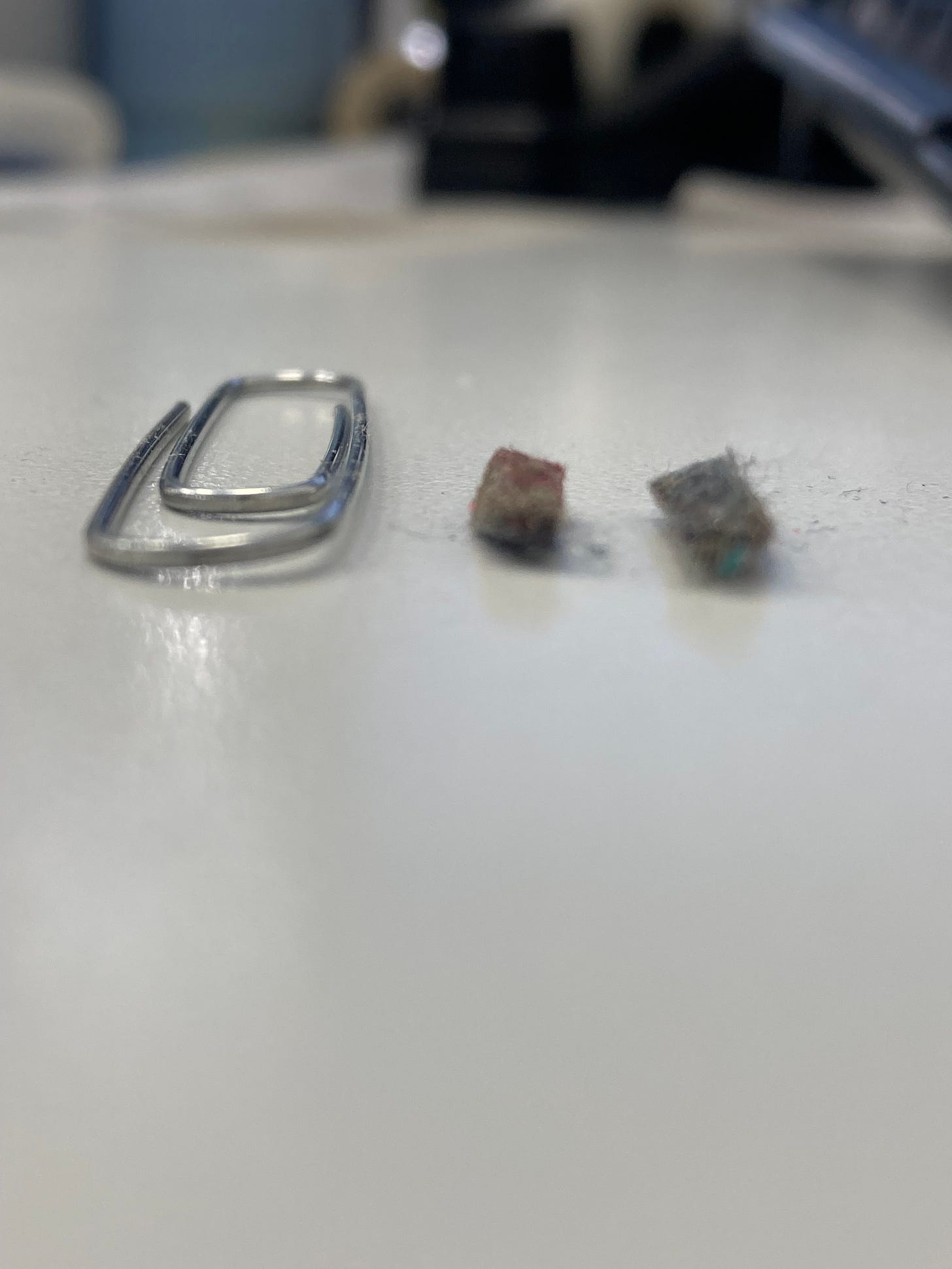

(4) Feed Dogs

Remove your needle needle plate and examine your feed dogs. Specifically, examine the grooves in between the feed dog teeth. It’s a prime area for compacted lint to build up.

With your canned air or lint brush, clean between the feed dogs and clear out that compacted lint.

Why is cleaning out this area important? I have seen machines come in for service where the sewist complains that their machine isn’t feeding fabric well. Upon closer inspection, the feed dogs look low; they barely rise above the needle plate, so it’s no wonder they cant grip the fabric adequately. However, when I take off the needle plate I see compacted lint in the feed dogs. The lint has gathered up so much that the lint is actually pushing the needle plate upward. The feed dogs aren’t low; the needle plate is high. If you remove that compacted lint, then the feed dog height should improve, though further adjustment still may be needed. That’s why you want to prevent compacted lint in the first place with preemptive cleaning

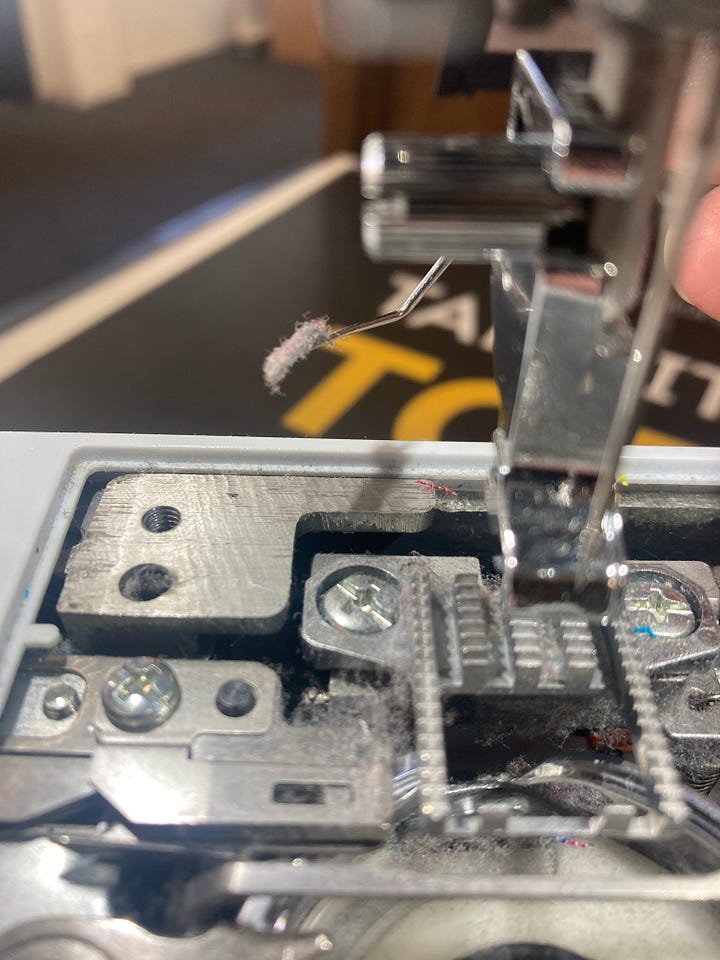

(5) Needle Threader

At the epicenter of your machine’s needle threader is a tiny wire hook that passes in and out of the needle eye. As you can see in the photos below, lint can get caught around that tiny wire hook. When it does, there is good chance that your needle threader will not work properly because the lint prevents the tiny wire hook from hooking onto the thread. I recommend that you occasionally blow out your needle threader with canned air to prevent lint buildup from happening.

I hope you found this information helpful.

As you saw, some of the photos in this newsletter had intense lint buildup. If you clean your machine regularly, you will rarely (if ever) see this kind of compacted lint.

Thank you.

-Cale

Canned air works great unless you mistake a can of glue for air. Ask me how I know. :(

Wow! Thank you for this info.😀😀