Recently, we had the pleasure of servicing two Bernina 930 Records and two Bernina 830 Records within a span of 36 hours. Being that these two models are among the most iconic sewing machines of the latter half of the 20th century and remain the machine of choice for thousands of sewists around the world today, I thought it would be a good opportunity to take a deeper dive into each service. What had to be done to each machine? Why? Bernina began manufacturing the 830 Record in 1971 and the 930 Record in 1981— how are they holding up in 2024, 40-50 years after originally manufactured?

Let’s take a look.

Bernina 930 Electronic (1/2)

As you can see from the repair ticket below, the first 930 Record was brought in for a very specific reason, which is that the owner noticed a burning smell after sewing on it for about 15 minutes. She said that the smell was emanating from the foot pedal/power cord, but our technician examined the power cord/foot pedal and notes that it was working perfectly fine.

So what was the cause of smoky smell?

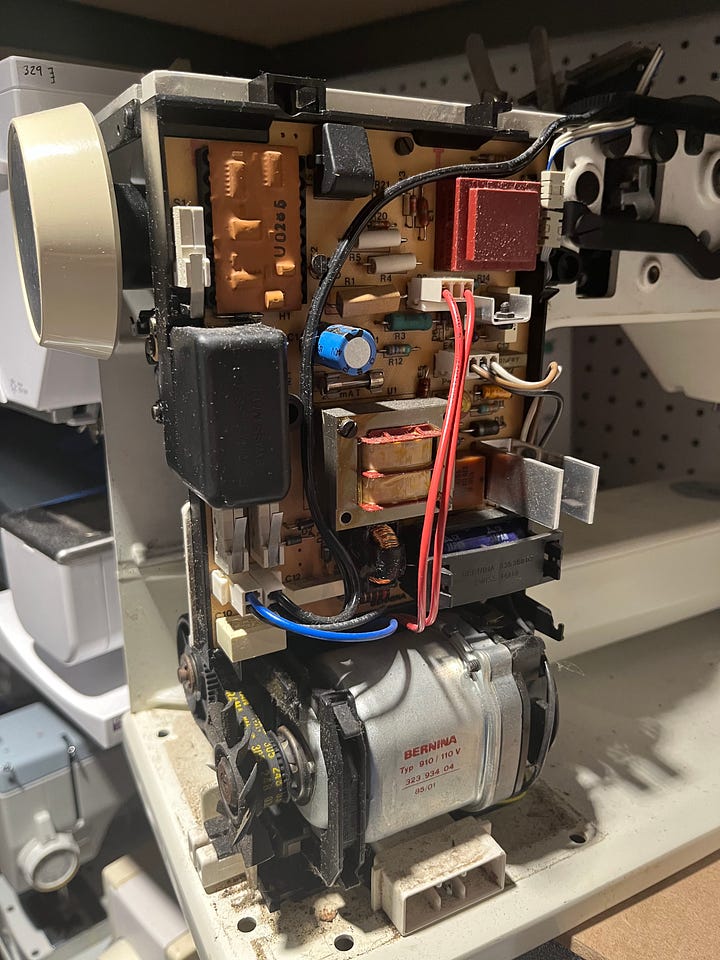

The Bernina 930 Record was designed with a noise suppressant capacitor, and that capacitor had blown up from old age, which caused the burning smell.

What is a noise suppressant capacitor? A noise suppressor capacitor is a passive component that reduces noise in electronic devices by blocking direct current (DC) while allowing alternating current (AC) to pass through. This allows the device to operate properly by supplying only the necessary DC components, while removing unnecessary signals (noise).

Fortunately, the sewing machine doesn’t need the noise suppressant capacitor to function properly. The machine may sound a little bit louder without the capacitor, but its absence does not have a negative effect on the operation or stitch quality. As you can see in his notes, our technician simply removed the capacitor and cleaned the smelly residue it left from blowing up. He did not replace it, as the capacitor does not effect the stitch-making function of the the machine.

In addition to solving the problem of the smell, he gave the machine complete COA (Clean, Oil, Adjust), which is our shop’s terminology for a tune-up. I’ve already written an article about what a COA specifically entails, which I’ll link to you below:

Bernina 930 Electronic (2/2)

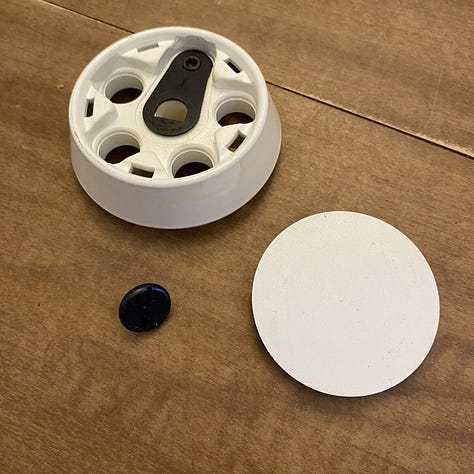

The second 930 Record was also brought in for a specific reason, which was that the handwheel had fallen off. While it may sound simple, sewing machine handwheels, especially those on older mechanical machines like the Bernina Records, are a pain to take off and put on.

Because the handwheel manually declutches (most modern machines declutch automatically) when winding a bobbin, they are constructed of multiple components that fit together like a puzzle. If one fails to pay close attention to the orientation of these parts when removing the handwheel, then it will be very difficult to put it back together properly.

As you can see in the technician’s notes, he also removed the blown noise suppressant capacitor on this second 930 Record. While the owner didn’t note any smell, the blown capacitor could explain why she said the machine sounded louder than normal, though that noise could also be caused by lack of lubrication, which would be solved by the oiling the technician performed during the COA.

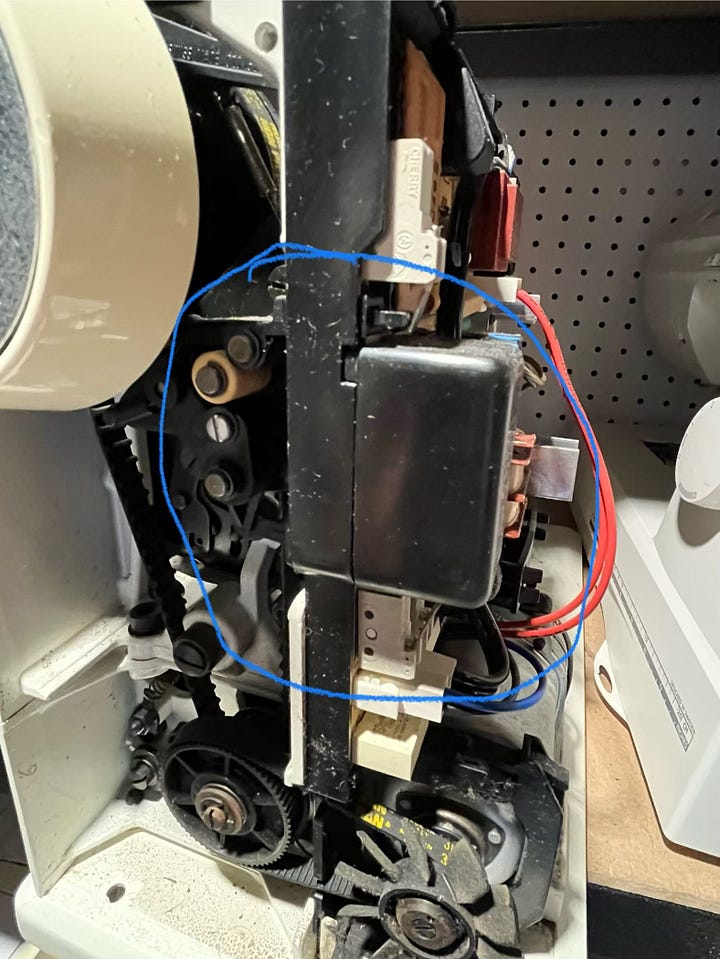

The technician also notes that he adjusted the synchronizer. What synchronizer?

The 930 Record was designed with a very early version of needle-up stop, meaning you take your foot off the foot pedal and the needle stops in the highest position, opposed to other mechanical machines where the needle stops at whatever position it is at when you take your foot off the foot pedal. The mechanism that gave the 930 this capability was electro-mechanical, which is unlike today’s synchronizers which are strictly electronic and relatively simple.

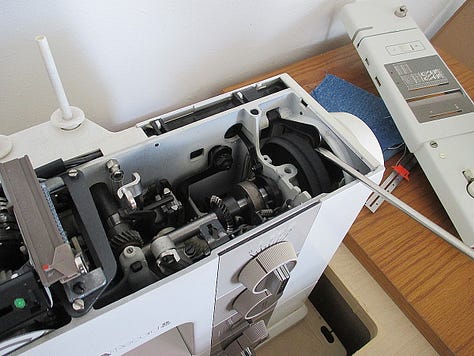

The 930 Record had a PCB (printed circuit board) that triggered a solenoid that fired a lever that would connect with a heavy spring-like clutch capable of stopping take up lever and needle in correct upmost position. This mechanism is nearly 50 years old and fairly archaic by today’s standards. In this case, our technician saw that the needle wasn’t stopping in highest position, so he had make a mechanical adjustment to the mechanism to get it to stop in the correct position.

I realize this article is getting fairly long, so I am going to save our examination of the two Bernina 830 Records until next week. However, I want to quickly review some of our findings from today.

First thing first— the 930 Record is one heck of a machine. Notice that neither of these machines came into the shop for stitch quality issues, nor were there any notes from the technician reporting issues regarding timing, needle-hook clearance, feed dog height, tension, broken gears, etc. Even back in the 1980s, Bernina truly made a spectacular product. Having sewn on these machine myself, I can see why sewists in 2024 choose to make the 930 their machine of choice. The touch and feel of the 930 is incredible, and the stitch quality remains top-tier.

With that said, using a vintage machine like the Bernina 930 Record does come with vintage machine problems. As we saw, the handwheel design is older and more difficult to reinstall if it ever falls off. Components like the noise suppressant capacitor will eventually fail due to age and may not be able to be fixed, especially if you don’t live in proximity to a technician who has experience fixing vintage European machines.

Another thing I wan to highlight is the difference between of vintage machines that are computerized versus vintage machines that are purely mechanical. The Bernina 930 Record is essentially mechanical and does not rely on a PCB board to sew. In the case of the second 930 Record we examined, even if we couldn’t fix the synchronizer and the user lost the needle-up stop (which is certainly a nice feature), she would still be able to sew on the machine perfectly fine. Owners of vintage machines like the Bernina 1130 or the Viking 960 or the Pfaff 1471 may not have such luck. The stitch-making functions of those machines do rely on a PCB, and now we’re talking about a relying on 50 year old electronics. Replacing such a component is not easy, as many of these parts are no longer being made. I touch on this difference between mechanical vintage machines and electronic vintage machines in a previous article I wrote, My Favoite Vintage Sewing Machines.

Thank you for reading.

If any of you own a Bernina Record, or still use a vintage machine as your machine of choice, I’d love to hear from you in the comments. Also, if you like my work, please feel free to share my publication with your fellow sewists via email, social media, word of mouth, etc.

-Cale

Like one of the other commenters, I received a Bernina 830 record for my 16th birthday and Christmas. I am now 67, and it is still running strong and is my “daily driver”. When I was looking for a machine to have at a cabin … the all metal 830 is portable, but not fun to carry around … I bought a second used 830. Added benefit: no learning curve, and now I have one each to leave to my daughter and daughter in law! Someday a long time in the future. LOL.

I own four 930’s and love them. My mom bought one for my college graduation in 1984 & bought one for herself. Then mom needed one to keep at her lake cabin so I bought her a second one. Years later, I bought another one. Mom has passed. I gave my daughter one of mom’s machines. I use mine at home. I teach a beginning sewing class in middle school, I start out by having 2 students work on my 930s with me between them. 930s are working horses!