While the primary goal of this newsletter is sewing machine education, another subject matter I will touch on every once in a while is business. The Sewing Machine Shop is the quintessential small business, as well as a family business. Since it happens to be my family’s business, I am fond of the founding stories my father and uncle have told me. Not only are these stories interesting and entertaining, I also find them informative. They show certain truths of the world that words don’t capture, especially the realities of small business.

These days The Sewing Machine Shop is a successful, established business. We are fortunate to have a good reputation, a well-trained staff, and a robust customer base full of people who are passionate about sewing. In our world, that is a combination conducive to success, but it hasn’t always been this way. My dad and my uncle have told me stories about the early days of the shop, some of which sound completely foreign to me. Sure, we have our struggles today, but they are a completely different class of struggle than what they dealt with back in the beginning. Risk is inherent to any small business, but even the risks they took were of a different class, too.

As I said earlier, I think hearing the stories themselves shows the truth better than words can. So, in this edition of The Sewing Machine Newsletter I am going to share a couple of stories my Uncle Marty told me about the early days of the shop. I think you’ll see what I mean.

It’s also his birthday in a few days, so happy birthday, Uncle.

Marty is the oldest son in his family. He has an older sister, Adriana, and 3 younger brothers— Tomas, Bill, and Dan (my dad, the youngest). Marty was 7 years old when the family immigrated from Buenos Aires to Richmond, CA (1963). In America, his father, Ramon, fixed sewing machines two days per week as a side hustle. Marty often tagged along. He remembers how Ramon would put an old junker machine in front of him and hand him a set of screwdrivers. "Take apart everything you can," Ramon said. Marty did as he was told, disassembling machines into hundreds of little parts. In 1974, when Marty was older, he began working full-time at Berkeley Sewing Machine Company as a technician. A few years later he invested in a van and some tools and started a one-man traveling sewing machine repair business called Sewing Machine Engineering.

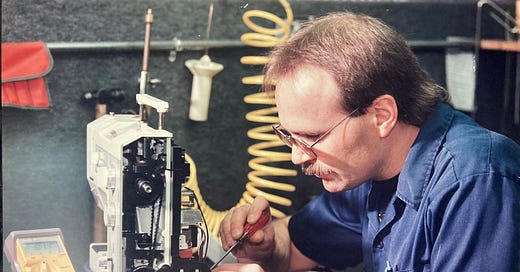

This was the late 70’s/ early 80’s. The home sewing machine industry was not nearly as big as it is today, so back then Marty was primarily working on industrial machines. Because he knew how to fix industrial machines, he naturally had a lot of clients who did upholstery. One of these upholstery clients in particular is the subject of a few great stories that encapsulate the early days of the business. This guy gave Marty a decent amount of work, but he also caused a handful of problems. Let’s call him Bobby.

Bobby was a nice enough guy, but he also had a bit of a drug problem. Speed, amphetamines— that kind of stuff. Despite his personal issues, Bobby was the most skilled upholsterer Marty had ever seen. He would reupholster the interior of classic cars with incredible leatherwork, and he made a good chunk of change doing so. He used an industrial walking foot machine, and Marty was his go-to guy for repairs.

As I mentioned earlier, Marty had a van that he used for traveling sewing machine repair, and that van was full of tools. Now, similar to other mechanics, a sewing machine technician will have his flathead screwdrivers, Torx screwdrivers, Phillips, hex keys, etc. However, he will also have a bunch of tools and gauges that are highly specific to sewing machine repair. For example, he’ll have a gauge made by Bernina whose sole purpose is to measure the needle-hook timing on a specific Bernina machine. Or a gauge made by Pfaff to adjust the positioning bracket for the bobbin case basket. You get the picture: extremely specific tools one can only acquire from the manufacturer. Not just screwdrivers you can pick up at any local hardware store.

Anyway, one day Marty’s van was stolen. The police found it a couple of days later in the parking lot of a church off of San Pablo Dam Road in El Sobrante. All the tools were gone. In order to work, Marty would have to get a whole new set of tools. But, as luck would have it, he happened to get a phone call from Bobby:

“Hey Marty, I am looking to sell some tools and I thought you might be interested in buying them for your machine repair. Want to meet up and take a look?”

So, Marty met up with Bobby, and, well, what do you know! The tools Bobby was selling were the exact tools that Marty needed to buy in order to restock those that were stolen from his van. In fact, the tools were identical. Not just the Torx screwdrivers, not just the Philips and the flatheads, but every gauge he needed to adjust his Pfaff’s and Bernina’s and Singer’s and Juki’s.

“What do you say, Marty? You interested in buying ‘em? I’ll give you a good price.”

“No, Bobby, I don’t want to buy them, but I’ll tell you what: these tools are identical to the ones that were stolen from my van the other day, and as long as you hand them over now and walk away, I won’t call the police and tell them that information. What do you say?”

Bobby said yes. Marty got his tools back. But that’s not the last time he’d deal with Bobby.

Eventually, Marty and Dan combined forces and began renting a storefront in El Sobrante. The business plan was simple: Marty would fix machines and Dan would sell them. Initially, the name of the business was still Sewing Machine Engineering, though they would soon change it to The Sewing Machine Shop.

Despite the stolen van incident, Bobby still came to my Uncle for sewing machine repair. These days, if a customer did something like that they’d be banned from the shop, but back then the shop was young and they needed any business they could get.

One day Bobby came into the store, not for repair, but to purchase a new machine. Bobby put up half the money upfront for a new industrial walking foot machine and financed the rest. In 2023 The Sewing Machine Shop uses Synchrony Bank for financing, but back then Dan and Marty were the financiers. It was a big risk, and the risk didn’t pay off. Bobby didn’t pay his first monthly installment. Or the second. Or the third. Bobby never paid a cent of what he owed. Giving him a second chance was a poor business decision. But, as they say, you live and you learn.

A year or so after acquiring his new industrial walking foot machine, Bobby brought the machine back into the shop to get it fixed. Marty and Dan couldn’t believe their eyes. The guy must have completely forgotten how badly he screwed them over, and they didn’t remind him. They casually checked the machine in for repair, just like they would any other customer. They gave Bobby a quote, told him they’d fix it as soon as they could and would give him a call as soon as it was ready to be picked up. As you can probably guess, Sewing Machine Engineering repossessed that machine. Bobby didn’t get it back until the rest of the balance was paid, and Marty and Dan never offered him in-house financing again.

I hope you enjoyed this edition of The Sewing Machine Newsletter. Typically we will be publishing articles on sewing machine education, but I like to mix in this type of stuff every once in a while.

-Cale

Nice story, Reminds me of when I was growing up in my old neighborhood with some those same type of characters. I remember a friend owned me money and paid me back with a counterfeit $20 bill.

Love your story!