Industrial Sewing Machines: Pros & Cons

Breaking down the reasons why someone might want to add an industrial machine to their arsenal.

Greetings everybody,

In this edition of The Sewing Machine Newsletter, we'll explore the pros and cons of industrial sewing machines. Even if you're not currently looking to purchase an industrial machine, this overview will highlight key aspects of industrial sewing machine design.

I hope you find it helpful.

—Cale

Pros of Industrial Sewing Machines

When comparing industrial sewing machines to home sewing machines, three primary benefits stand out:

Powerful Fabric Penetration: Industrial machines are capable of easily penetrating thick and heavy fabrics that would challenge or stall a typical home machine.

Ability to set knot with heavy thread: Industrial machines are better at setting secure knots using heavier threads, ensuring durable, professional-quality stitches on heavier fabric.

Reliable Material Feeding: Walking foot industrial machines are better at feeding heavyweight or layered materials.

(1) Ability to penetrate heavy fabric

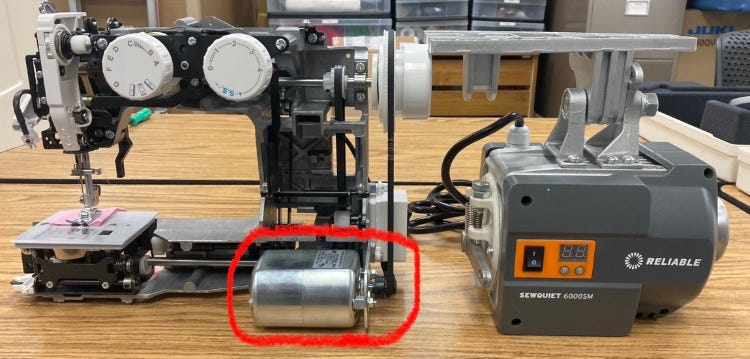

Industrial sewing machines are significantly more powerful than domestic machines, and a major reason why is because of their motor strength. Consider the photo below: On the left, you'll see a common, quality home sewing machine motor (circled in red). On the right is the brushless servo motor powering our industrial machines. Notice how much larger and more robust it is compared to the domestic motor.

This size difference directly translates into substantial power. The domestic sewing machine uses a modest 60-watt motor, while the industrial machine is equipped with a powerful 550-watt motor—nearly ten times stronger. This immense power allows industrial machines to penetrate heavy fabrics effortlessly.

However, the motor isn't the only robust component found in industrial sewing machines. The needle bar, upper and lower shafts, feed dog mechanism, hook mechanism, and even the needle itself are all considerably larger and sturdier compared to those on domestic machines. The combination of these heavy-duty components and a powerful motor enables industrial machines to effortlessly penetrate materials that would typically cause home sewing machines to struggle—such as multiple layers of thick leather, canvas, or vinyl.

The ability of a sewing machine to penetrate material effectively cannot be overstated. The stitch itself is formed beneath the needle plate, precisely when the needle interacts with the hook mechanism and bobbin thread. If the machine lacks the power to push the needle through dense material, it never even reaches the critical point of stitch formation.

2. Ability to Set a Knot with Heavy Thread

A sewing machine creates stitches by forming a lockstitch—a strong knot made between the top thread and the bobbin thread. Ideally, we want this knot to settle securely between the fabric layers, as this placement provides the strongest and most durable hold.

The knot is formed beneath the needle plate, in the bobbin case area. As the needle descends, it is timed precisely with the hook mechanism to loop the top thread and bobbin threads together. Then, as the needle moves upward, the take-up lever cinches the knot tightly into position within the material. The video animation below beautifully illustrates this intricate process:

When sewing heavy materials, we typically use heavier thread. By "heavier," I mean thread that is literally thicker than the type commonly used for quilts or cotton projects. Naturally, thicker thread results in a physically larger knot.

Home sewing machines often struggle to properly set this larger knot into the fabric. The primary issue is an insufficient take-up stroke—the vertical distance the take-up lever travels from its lowest point to its highest point. On domestic machines, this stroke is often too short to effectively pull a thick knot fully up into the fabric layers. As a result, the knot ends up sitting loosely on the underside of the fabric, as shown here:

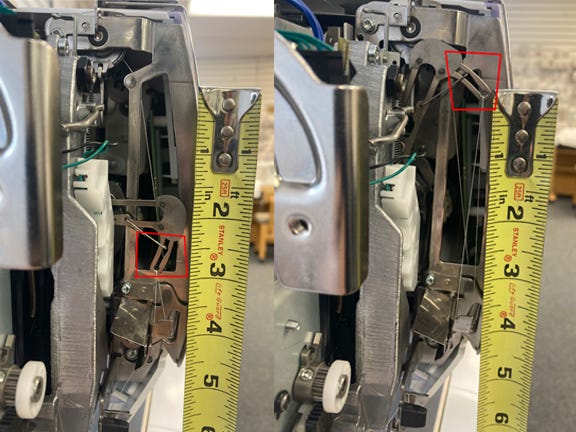

Industrial machines are specifically designed with a longer take-up stroke than domestic machines. This increased distance—measured from the take-up lever's lowest position to its highest—allows the machine to pull heavier thread knots fully into thick fabrics, setting the stitch securely in place. In the photo below, you can see me measuring the take-up stroke of an older Adler industrial sewing machine, which has an impressive 4-inch stroke.

Compare that with the Bernina 770 Plus (in the photo below), one of the more powerful home sewing machines on the market. The take-up stroke is only 3 inches.

Several factors beyond take-up stroke also contribute to an industrial machine’s ability to sew effectively with heavier thread. For instance, industrial machines use larger needles with larger eyes, which handle thicker thread more efficiently. A larger needle eye reduces friction as the thread passes through, decreasing the likelihood of shredding, snagging, or other issues that could disrupt stitch formation.

I’m on the verge of going down a rabbit hole, so I’ll move on after this last point— As you’ve heard me say already, in order for the stitch to form properly the thread must do a somewhat complicated dance around the hook mechanism (below the needle plate). Excuse the corny metaphor, but industrial machines are designed with a less crowded dance floor. There is more space for heavier thread to do that dance successfully. There is no free-arm to squeeze parts into, no zig-zag mechanism or auto-thread trimmer to worry about. The engineers don’t have to compromise the design for these features, so they can focus on making a machine that does one thing extremely well: straight-stitch with power.

3. Ability to Feed Heavy Material

Note: There's an entire class of industrial straight-stitch machines designed specifically for sewing cotton and lighter-weight materials. However, in this section, I'll focus exclusively on machines tailored for sewing exceptionally heavy materials—perfect for those interested in leatherwork, upholstery, and similar heavy-duty projects.

Just as industrial sewing machines can easily penetrate heavier materials, they also excel at feeding these materials smoothly and reliably (though some models do this better than others). Industrial machines built for heavier fabrics, such as automotive upholstery, often incorporate a special mechanism known as a needle-feed system, which differs significantly from the feeding systems found on domestic sewing machines.

On a typical home sewing machine, fabric feeding occurs only after the needle has fully exited the material and returned to its highest position. The process looks like this:

Needle down → Needle up → Feed fabric → Needle down → Needle up → Feed fabric, and so forth.

In contrast, an industrial needle-feed machine feeds the fabric while the needle is still inserted into the material, ensuring more consistent movement and control:

Needle down → Feed fabric → Needle up → Needle down → Feed fabric → Needle up, and so forth.

The video below demonstrates an industrial needle-feed machine in action, clearly showing this process:

The needle-feed mechanism is particularly beneficial because the needle itself helps hold multiple layers of heavy fabric together while they're being fed, preventing misalignment (AKA slippage). The machine shown in the video above is the Juki DNU-1541, a popular walking-foot industrial machine equipped with a needle-feed system.

On the Juki DNU-1541, not only is the fabric fed while the needle is down, but the feed dogs and walking foot also work simultaneously to move the material smoothly and evenly. This combined needle-feed and walking-foot design allows users to sew through exceptionally thick fabrics with remarkable ease.

The Juki DNU-1541 is widely regarded as the go-to choice for upholstery professionals. For example, one of our valued customers, Compass Canvas in Point Richmond, CA, specializes in marine upholstery. Their team relies on a stable of five or six Juki DNU-1541 machines to handle demanding projects effortlessly.

Cons of Industrial Sewing Machines

I am going to try to make this section short and sweet, as the negatives of industrial machines are pretty straightforward.

1. Size and Weight

Industrial machines are considerably larger and heavier than home machines. Even a relatively small industrial model, like the Juki DDL-5550, weighs around 75 pounds—and that's just the machine head. Most industrial sewing machines have separate motors mounted underneath the machine table, adding even more weight and bulk. If the machine needs servicing, you'll likely have to detach the heavy machine head and bring it into the shop separately.

For reference, the standard dimensions of an industrial sewing table are 48 inches long by 20 inches deep.

2. They (Usually) Only Do One Type of Stitch

Industrial sewing machines are highly specialized, typically designed to perform only one specific type of stitch. This specialization makes sense because industrial machines are built for commercial settings, where each machine performs a dedicated task. For example, factories often have separate assembly lines for straight-stitch machines, overlock machines, coverstitch machines, and so forth.

If you have limited budget or space and require a machine capable of multiple stitch types (such as straight stitch, zig-zag, or buttonholes), an industrial machine may not currently be the best fit. Many customers ask me about industrial machines capable of both straight and zig-zag stitching, but today it is exceedingly rare to find a modern, well-built, affordable industrial model with that capability. If you ever come across a Bernina 217 in good working condition, you have found a gem. These machines are capable of straight stitch and zig-zag, but they are no longer produced and increasingly rare.

The Queen of Denim sews on a Bernina 217. . . .

The Queen of Denim

A few years ago I received a phone call from a woman asking if we carried needles for her Bernina 217. It’s not a common request, as the 217 is a rare industrial machine that does both straight-stitch and zig-zag. I was not sure if we carried those needles, so I put her on hold and went searching through the shelves where we stock all the industrial nee…

3. Less User-Friendly Than Modern Machines

Most modern home sewing machines come equipped with convenient features designed to make sewing simpler, quicker, and more enjoyable. Features such as automatic needle threading, automatic thread trimming, needle up/down positioning, and low-bobbin indicators are now common in domestic machines. In contrast, many industrial sewing machines typically lack these user-friendly additions.

Another notable difference involves needle design. Industrial sewing machines use needles with a completely round base, unlike home sewing machine needles that feature one flat side. On home machines, this flat side helps the user quickly insert the needle correctly—flat side facing backward aligns the needle eye precisely with the hook mechanism. Because industrial needles lack this flat side, users must manually position the needle at the correct orientation. This subtle difference frequently leads to mistakes, especially for sewists accustomed to domestic machines.

Thank you for reading!

Generally speaking, industrial machines are a joy to sew on for people who really like to sew and appreciate good sewing machines. They’re smooth, fast, strong, and deliver a beautiful stitch. If you’re curious about seeing the full scope of the sewing machine landscape, I recommend you find a local dealer and see if you can sit down to sew on an industrial machine. I am personally a fan of Juki and suggest you test-drive one of the following models: DNU-1541, DDL-8700, DDL-8000, or the J-150 (this last one especially for quilters).

Industrial machines are relatively inexpensive compared to domestic machines. For example, we sell that Juki DNU-1541 walking foot needle-feed machine for $2,200, and that price includes the head, table, and motor. It’s really not that bad for a machine that can sew genuine leather goods with ease.

I hope you found this edition of the newsletter to be informative and helpful.

Thank you for reading!

-Cale

Great article thank you so very much.

Yay! I have been waiting for more info on industrial machines! I would love to get more ever since I got my Kansai Special NW-8803GMG, but I don't have room! Do you know if there are industrial tables that are half or 3/4 size? (I sent samples of my fabric and thread to the people who sold me the machine, and they set it up for me, but I have sewn other fabric, and it just works. I got different gauge parts so I can change from coverstitching to hem, to flattening seams, to collarette. I'm still looking for a small metric ruler that has 0 right on the bottom to measure how high to put the feed dogs). When I was looking into industrials as a home sewer, I made a document about them https://docs.google.com/document/d/1vHQsMRfrVizF6a5aOVfBX_5WSzBoA9IpMQ8VNDCyutI/edit?tab=t.0 in case anyone else might find it helpful- feel free to edit and/ or share, or delete :)