"My Sewing Machine is Out of Time."

An explanation of what it means for a machine to be out of time.

“The timing on my sewing machine is off.”

You may have heard this phrase floating around the ether, but what does it really mean? In this edition of The Sewing Machine Newsletter, I aim to provide a clear explanation.

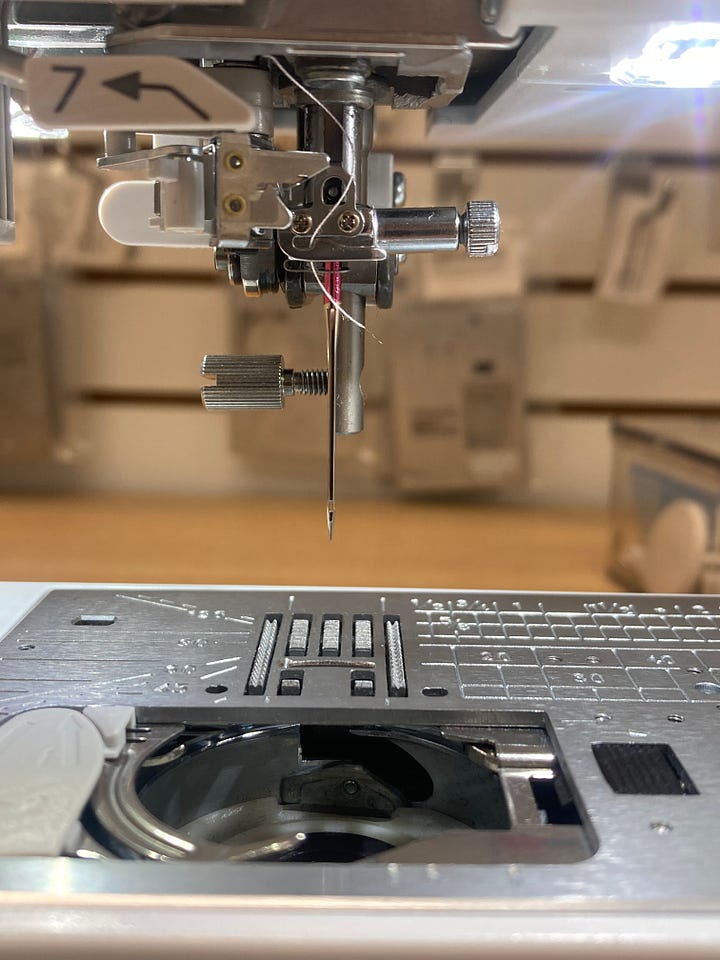

Needle-Hook Timing

When we say a machine is out of time, we are usually referring to the timing between the needle and the hook. A useful way to think of needle-hook timing is to consider the needle and hook’s relationship to each other during the stitch-making process. But, before we get to their relationship with one another, let’s first clarify what each part does individually.

The Hook

The hook rotates around the bobbin and bobbin case, no matter if your machine is designed with a rotary hook or oscillating hook.

For oscillating hook machines, the hook-point rotates back and forth on a vertical axis, rotating clockwise and then counter-clockwise.

For rotary hook machines, the hook-point continuously rotates counter-clockwise on a horizontal or vertical axis.

The Needle

The needle starts in its highest position, several centimeters above the needle plate.

As the machine begins the stitch-making process, the needle travels downward, down below the needle plate, until it reaches its bottommost position.

Once it hits its bottommost position, the needle travels upward, up above the needle plate, until it reaches its highest position again.

The Relationship Between the Hook & Needle

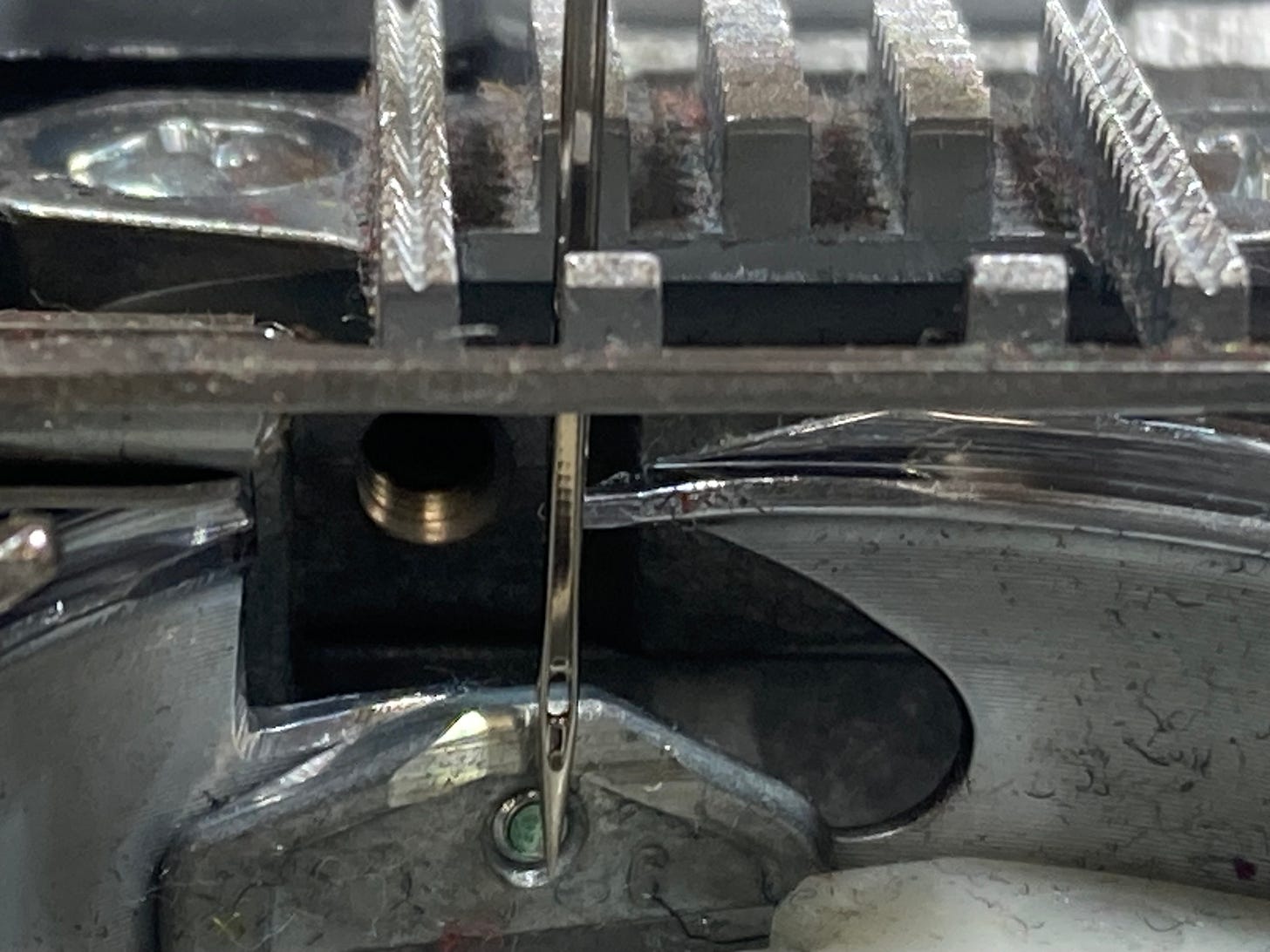

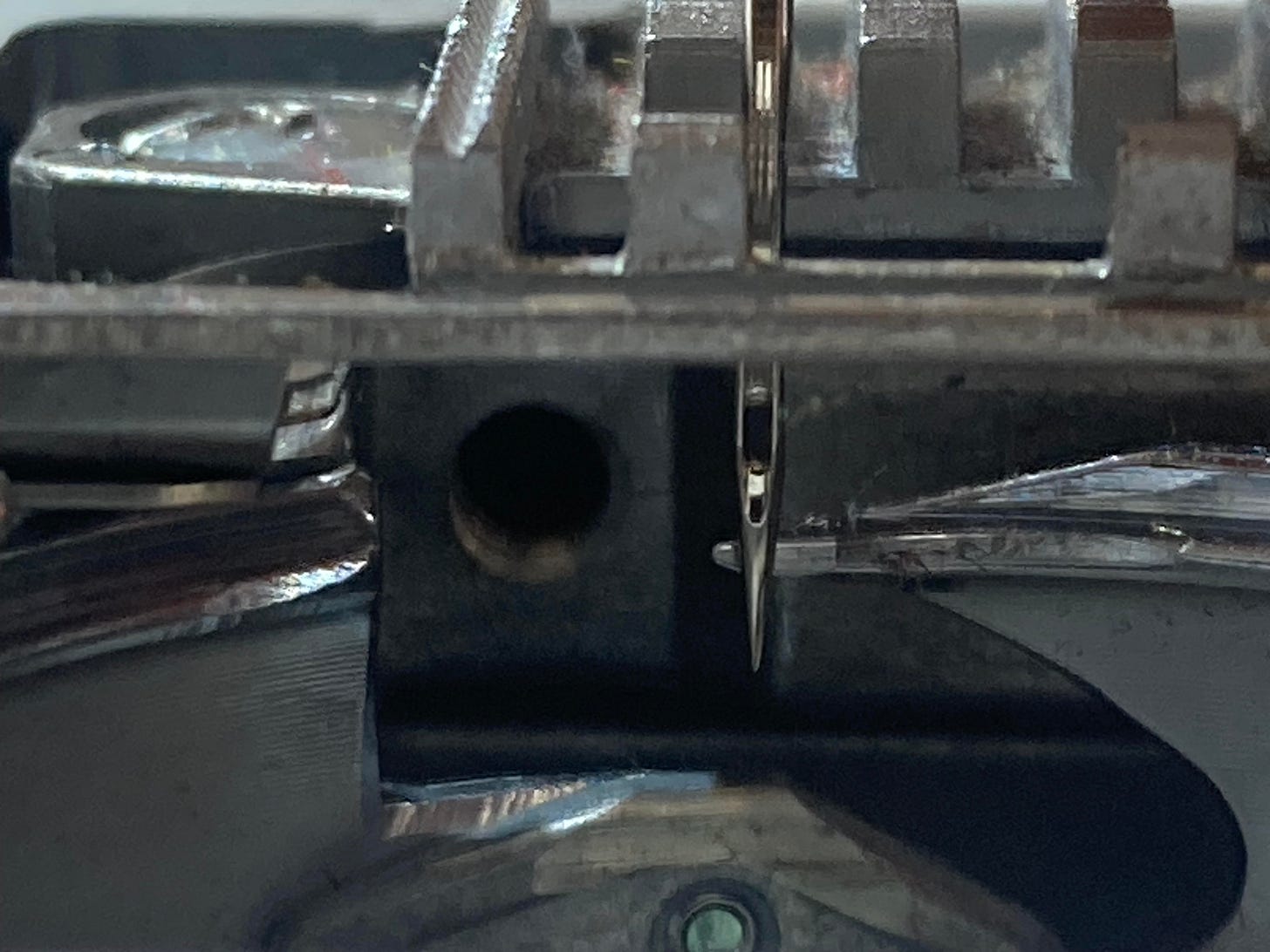

The needle’s revolution and the hook’s revolution are TIMED so that the hook passes behind the needle at a very specific point in time.

When the needle rises 2-3 millimeters above its bottommost position, the HOOK POINT should pass right above the NEEDLE’S EYE.

Why?

Because, as the needle rises upward, a tiny thread loop forms at the eye of the needle (on the backside of the needle). If the machine is correctly timed, the hook-point passes just above the eye of the needle and passes through the tiny thread loop. The hook catches the needle thread loop and then takes the needle thread with it as it completes its revolution around the bobbin case. As the hook completes its revolution, it helps form a knot between the needle thread and bobbin thread, a crucial step in the stitch-making process.

What does it look like for the needle-hook timing to be off?

If the needle fails to catch the thread loop from the needle eye, a stitch will not get made— AKA skipped stitches. There are many reasons why a machine would skip stitches, and the machine being out of time is one of those reasons.

Remember, we want the needle to pass just above the eye of the needle after the needle has risen 2-3 millimeters above its bottommost position. But, it is possible for the timing to be off in either direction— the timing could be advanced, or it could be retarded.

If the needle-hook timing is advanced, that means the hook is arriving at the needle earlier than it ought to. It still passes above the eye of the needle, but passes too high and fails to catch the needle’s thread loop.

If the needle-hook timing is retarded, that means the hook is arriving at the needle later/slower than it ought to. It passes below the eye of the needle and therefore misses its chance to catch the needle’s thread loop.

What causes a machine to go out of time?

One of the most common reasons a machine goes out of time is when I try to sew through something too thick for my machine to handle.

Imagine, I try to sew through thick leather on a small home sewing machine. My needle gets stuck in the material and stops moving, but, for a brief moment, the hook continues to turn. This would create advanced needle hook timing and potentially cause skipped stitches.

Can I fix a timing issue myself?

The short answer is no, probably not.

To fix a machine that is out of time, you have to remove the machine’s plastic cover and expose the internal components. Then you have to disengage the machine’s lower shaft from the upper shaft, and manually time the hook to the needle position. Sewing machine companies actually make tools and gauges specific to certain machine models to help the technician time the machine properly. So, if your machine is out of time, I recommend you take the machine to a trained technician.

HOWEVER !!!!

A needle that is bent or a needle that is not inserted all the way into the needle bar shaft may caused skipped stitches. If you get skipped stitches and think the timing is off, try replacing the needle first— replacing the old needle with a new needle could be a simple fix.

Thank you for reading.

Let me know what you think in the comments section, and feel free to share with anybody you know who might find this article interesting.

-Cale

Thanks for the very informative explanation about how the needle picks up the bobbin thread, and what out of time means in relation to a sewing machine’s function. I loved seeing the close up video it epitomises the saying a picture is worth a thousand words. Great article.

Another great article, Cale. Thanks for clearly explaining to us what the term, ‘out of time’ really means. The sewing community often uses that term as an all-encompassing description of a problem when a sewing machine is not working properly. Now we know what it really means. Thanks again.