Needles

A Simple Guide to Needles

Greetings everybody,

This edition of The Sewing Machine Newsletter will attempt to serve as a simple guide for needles. Like many things in the sewing machine world, the conversation about needles can be both straightforward and extremely technical. For this article, I will try to hedge toward the simple.

I hope you find it helpful.

“Reading” a Pack of Needles

System Number

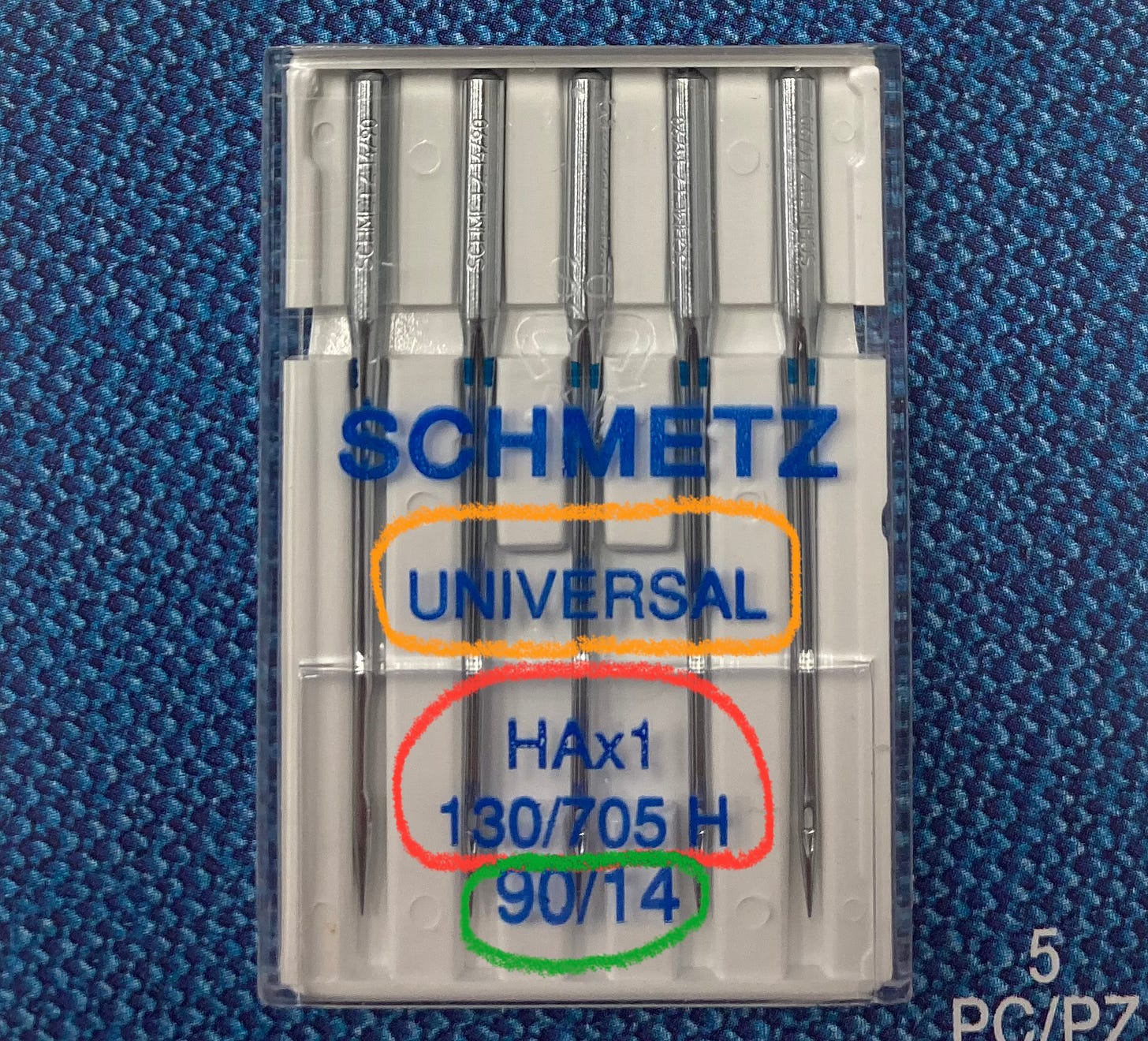

99% of all household sewing machines can take the exact same needle. You can successfully use the same needle on the Bernina 770, Janome MC6700, Brother NS80e, and Baby Lock Joy. Why? Because all of these machines are designed to take a needle of the same ”part number” or “system number.” On every pack of needles, the needle’s system number should be labeled clearly. The confusing part is that the system number can be different depending on the company that manufactures the needle. The most common designations for home sewing machine needles are 130/705H, HA1, HAx1, 15x1. This designation refers to the overall dimensions of the needle: its length, shank diameter, and, in this case for home sewing machines, a flat on the needle shank for easy positioning.

Needle Size

Within each system, there are different thicknesses of needles and different needle designs for optimum performance depending on the various fabric and specialty threads with which you are using to sew. Size examples are 80/12, 90/14/100/16 etc... with the largest or thickest size being 110/18. The first number is a European designation (80) and the second (12) is a U.S. designation. As the size of the needle increases, so does the thickness (girth) of the needle, as well as the size of the needle eye (e.g. a size 18 needle has a larger eye than a 12). The manufacturers assume that you will be using a larger thread with a larger needle.

Needle Type

The last variation is the needlepoint design.

There are dozens of variations in needle points. The most common and most widely used is a “Universal” needle. This needle can be used on all fabrics and should perform well for most applications. It is also the least expensive and therefore should be considered first. If you are getting acceptable results with this needle, then there is no need to pay more for a specialty needle.

Specialty needles usually have the fabric type or sewing technique added to the labeling and cost about 50-80% more than a Universal needle. Words you will see on the package are Quilting, Denim, Embroidery, Leather, Knit, Top Stitch, and Microtex. You will also still see words like “Sharp” or “Ball Point”. The thing to remember is that Quilting, Denim, and Microtex needles are all sharp-point needles, while Knit or Stretch needles are ball-point. So, if you have a Quilting needle in your sewing kit, feel free to use it on Denim, and vice versa.

General Needle Guidelines

Use a high-quality brand of needles. We recommend Schmetz needles. Schmetz is a German Manufacturer and is considered by most experts to be the best needle available.

Try your standard Universal needle first before moving on to specialty needles. I generally recommend you don’t preemptively use a specialty needle until you encounter issues. However, I have started recommending Topstitch needles to people who have trouble threading their needle, whether they are using their needle threader or threading by hand. Topstitch needles have a larger eye, which makes it easier to thread.

If you are not sure what size needle to use, try an 80/12 Universal. It is a great all-around needle for a variety of fabrics and thicknesses. This is what we use in our service department at The Sewing Machine Shop.

If you are getting skipped stitches on stretch/knit fabric, use a ballpoint or stretch-designated needle. This will reduce what we call flagging and aid in stitch formation and fewer skipped stitches.

If you are getting a slightly zig-zaggy straight stitch on wovens, try a Sharp, Denim, Microtex, or Quilt needle. The sharp point will break the fabric strand during penetration instead of deflecting to one side or the other of the fiber strand to create a better-looking straighter stitch.

If you are getting shredding or unusually high thread breakage, try a Topstitch or Embroidery needle. These needles have a larger eye (for example: an 80/12 may have the eye of a 110/18 allowing thread to flow through the eye more easily).

Common Misuses I see with Needles:

Too large a needle size is being used. A needle is not a nail. Try using a 12 instead of a 16 or 18 on thick fabric. It is easier for a pin to go through something thick than it is for a nail. Large-diameter needles can lead to many problems.

Too small a needle size is being used. Any size under an 11 should be extremely rare. Very few threads flow smoothly through the small eyes of 10 or below. Also, the small hole created with these needles is rarely large enough to provide a space for the thread knot to tuck into. Needle threaders rarely work and are often bent with needles smaller than an 11 or 12.

Expensive specialty needles are being used when not needed. Why pay more?

Dull or bent needles in your machine create a popping sound and poor stitch quality.

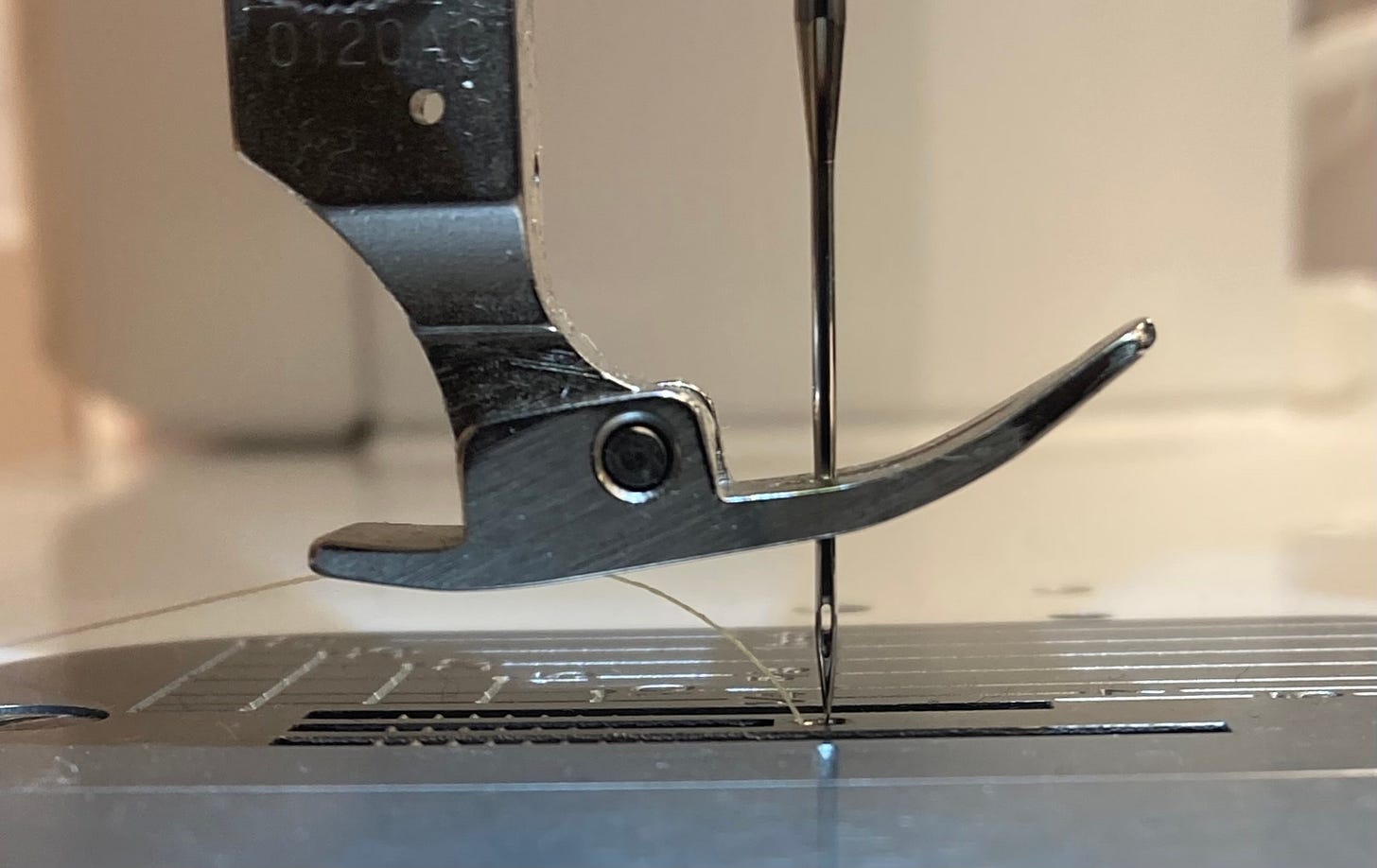

Needle not fully inserted or inserted backwards creating skipped stitches and thread breakage. When you insert the needle, the flat side of the needle should face the back of the machine. “Flat to the back” is the rule on the vast majority of home swing machines.

A Few Other Notes on Needles

I’ve seen manufacturers, such as Janome, state in a a machine’s instruction manual that the machine can only take Janome-branded needles. This is not true. I really wish Janome, who I love, would stop doing this.

Many modern machines are designed with a sweet automatic needle threader. However, the needle threader is prone to breaking if you use a needle size smaller than 80/12. I wrote about this in great detail in my two previous articles on needle threaders:

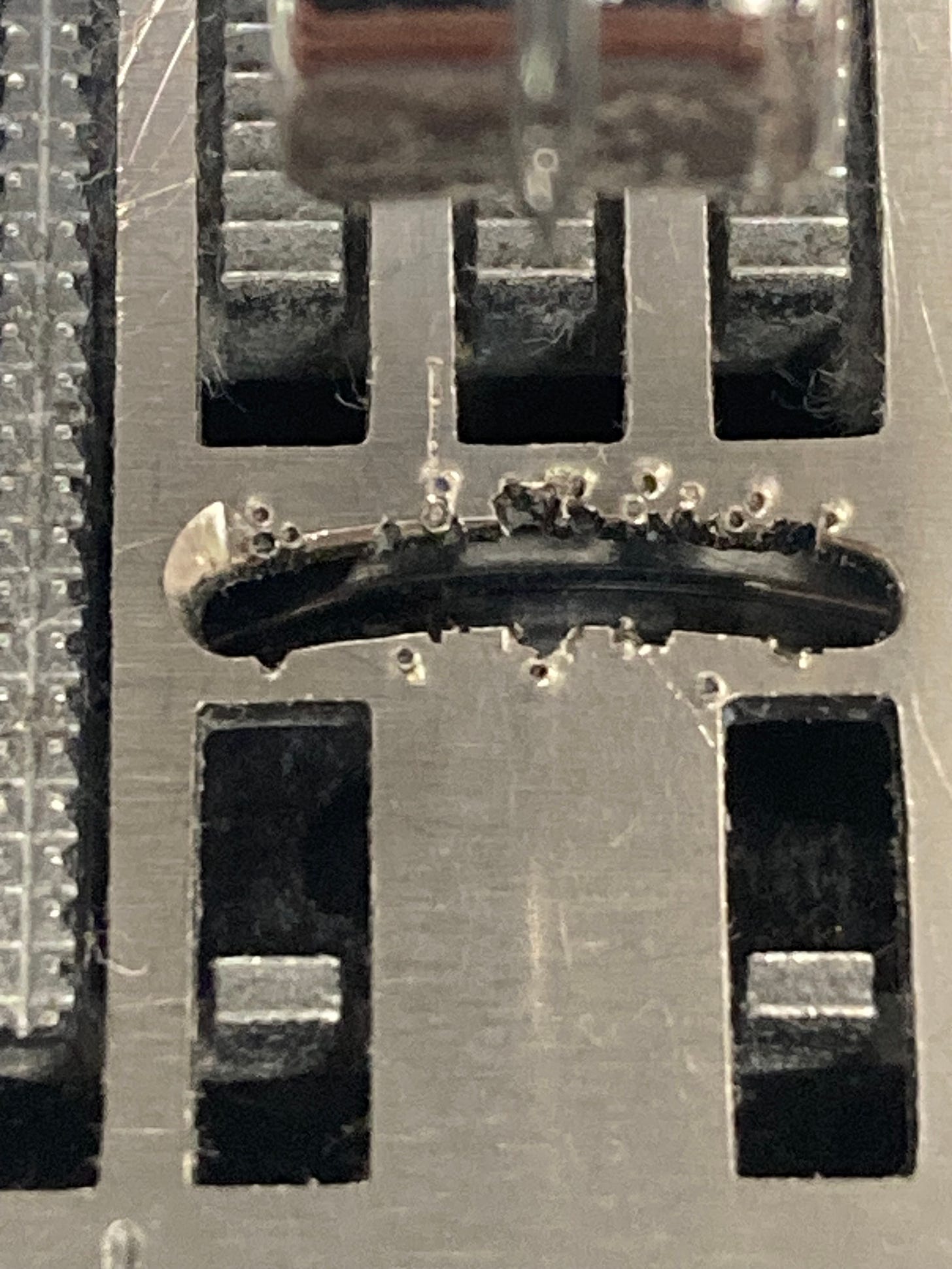

Needle Threaders Part 1 - Needle Threaders Part 2If I had to guess, I would say I troubleshoot *at minimum* 5 machines every day at The Sewing Machine Shop. I am going to start keeping a tally of the different issues I see and come back to you with the results after a month or so of data. My bet is that using a bent needle is the leading culprit of skipped stitches and poor stitch quality. That is all to say, if you suddenly encounter skipped stitches or poor stitch quality, change your needle and rethread your machine. I wrote about why bent needles are a problem in a previous article called Bent Needles & Skipped Stitches.

Thank you for reading. I hope you found this article helpful.

-Cale

BONUS ! ! !

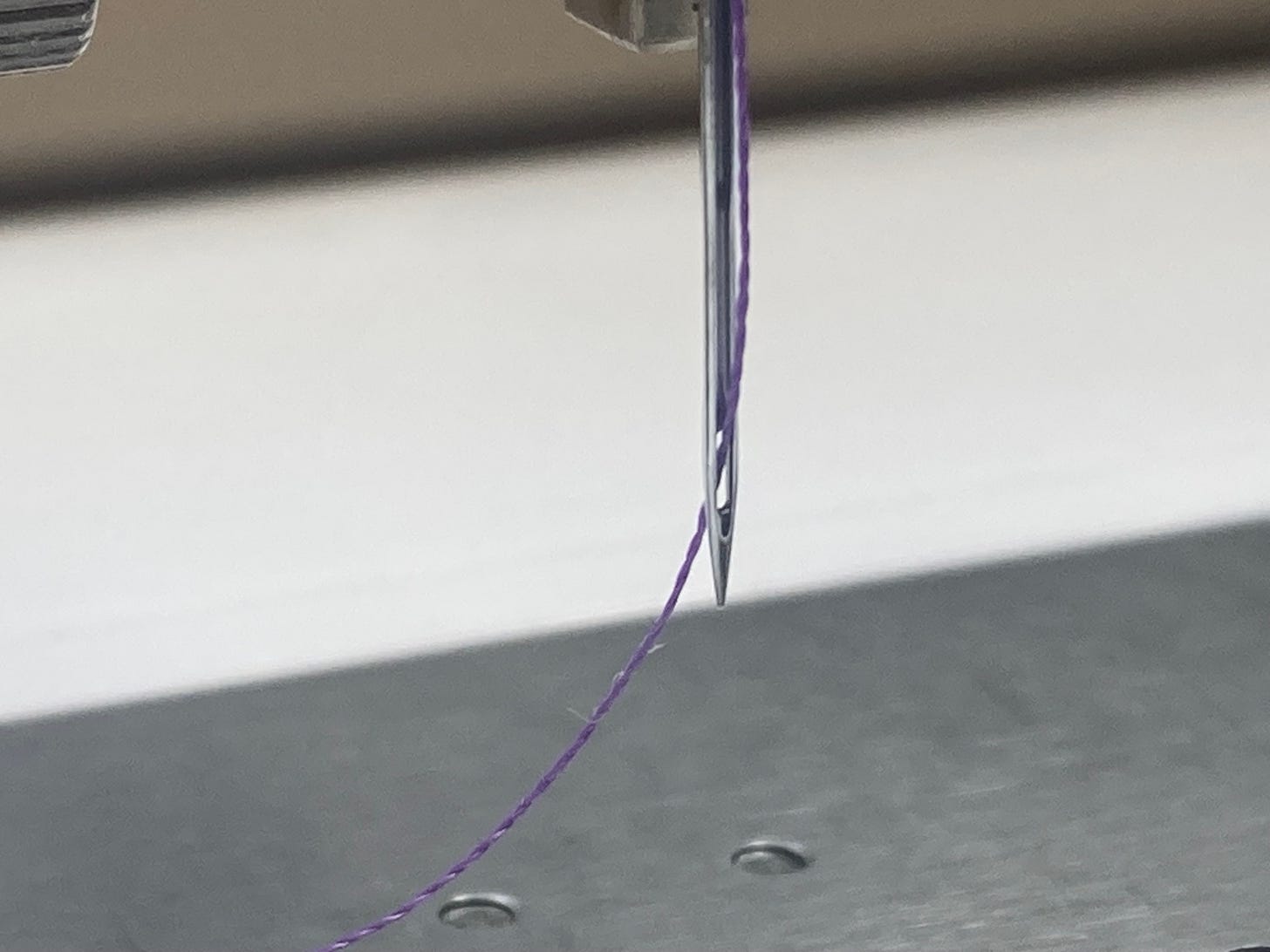

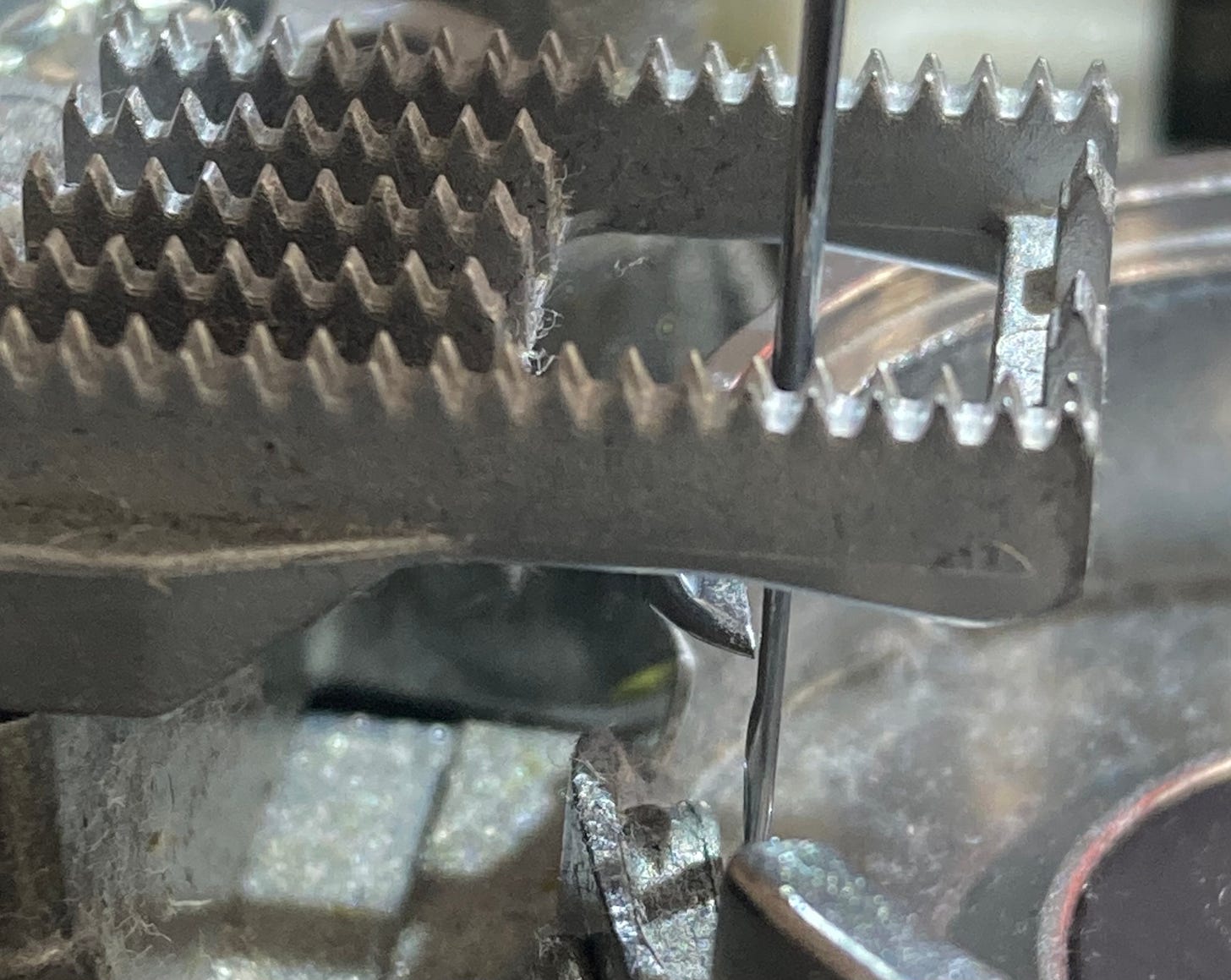

The Sewing Machine Needle Photoshoot You Didn’t Know You Wanted:

Cale;

You do a great Job on writing all your Articles! I’m learning so much & love your Tips!

Thank you so much!

Fascinating. All this information I didn’t know I needed!