Poor quality thread is a massive impediment to consistently good stitch quality. If you get it out of your life, you will run into less problems and be a much happier sewist.

Below, I will explain why.

Loop Creation & Skipped Stitches

Skipped stitches occur when the hook point fails to catch the thread loop formed at the needle eye as the needle begins to rise from its bottommost position.

One way the hook point can miss the thread loop is if the shape of the loop is distorted. Critical settings like needle-hook timing and needle-hook clearance may be perfect, but if the loop isn’t where it should be, then the hook point will fail to catch the loop and skipped stitches will occur.

Poor quality thread can possess certain characteristics that prevent it from consistently forming a proper (catchable) loop at the needle eye. For example:

Imagine we are using a thread that is excessively stiff. Due to that stiffness, it takes a long time for the loop to form. When the hook point passes above the the needle eye, the thread loop is shaped extremely narrow, more like a slit than a loop, making it more difficult for the needle to pass through successfully.

Imagine the thread possesses excessive viscosity (stickiness), causing it to stick to itself. Instead of forming a loop, it sticks to itself and twists into a figure-eight or some other strange shape. That makes it difficult for the hook point to consistently catch the thread loop. This is not conducive for success; it is conducive for skipped stitches.

Analogy:

The thread loop is like a doorway and the hook point is a person who needs to walk through that doorway. With quality thread, the doorway is where it ought to be– on the ground, 8 feet tall, 3 feet wide– and a person can walk through that doorway without issue. Poor quality thread warps the doorway, causing it to be 5 feet off the ground, or slanted at a 45 degree angle, or shrinks it down to 1 foot wide and 3 feet tall.

Thread Shredding & Breaking

Poor quality thread is more prone to shredding and breaking than high quality thread.

Why?

Poor quality thread is more uneven than quality thread, possessing kinks and crimps at random, and therefore is susceptible to snagging along the upper thread path.

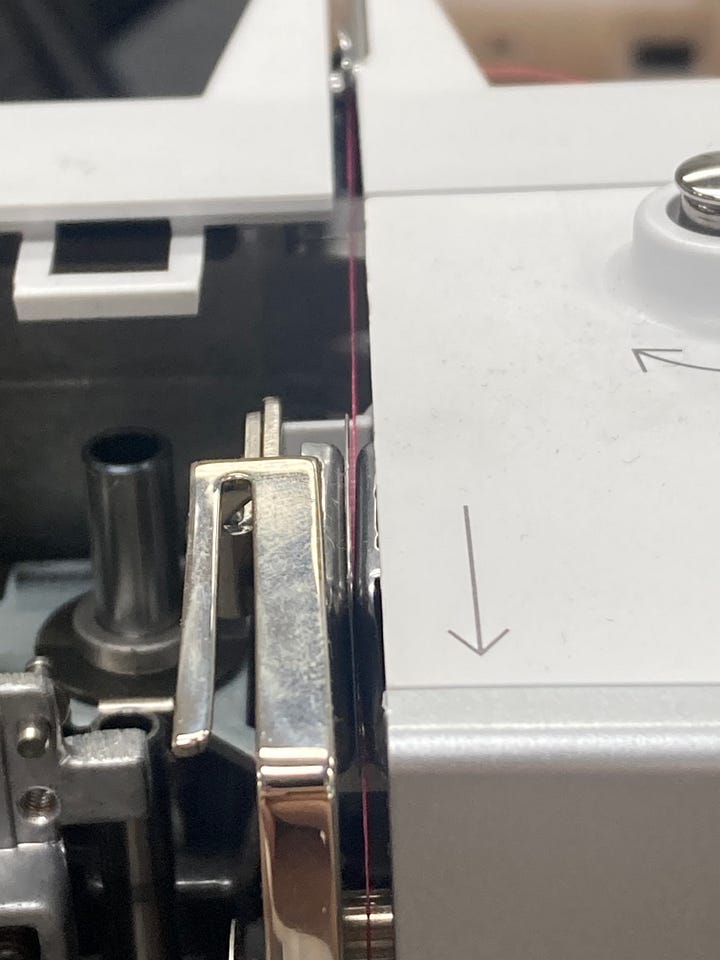

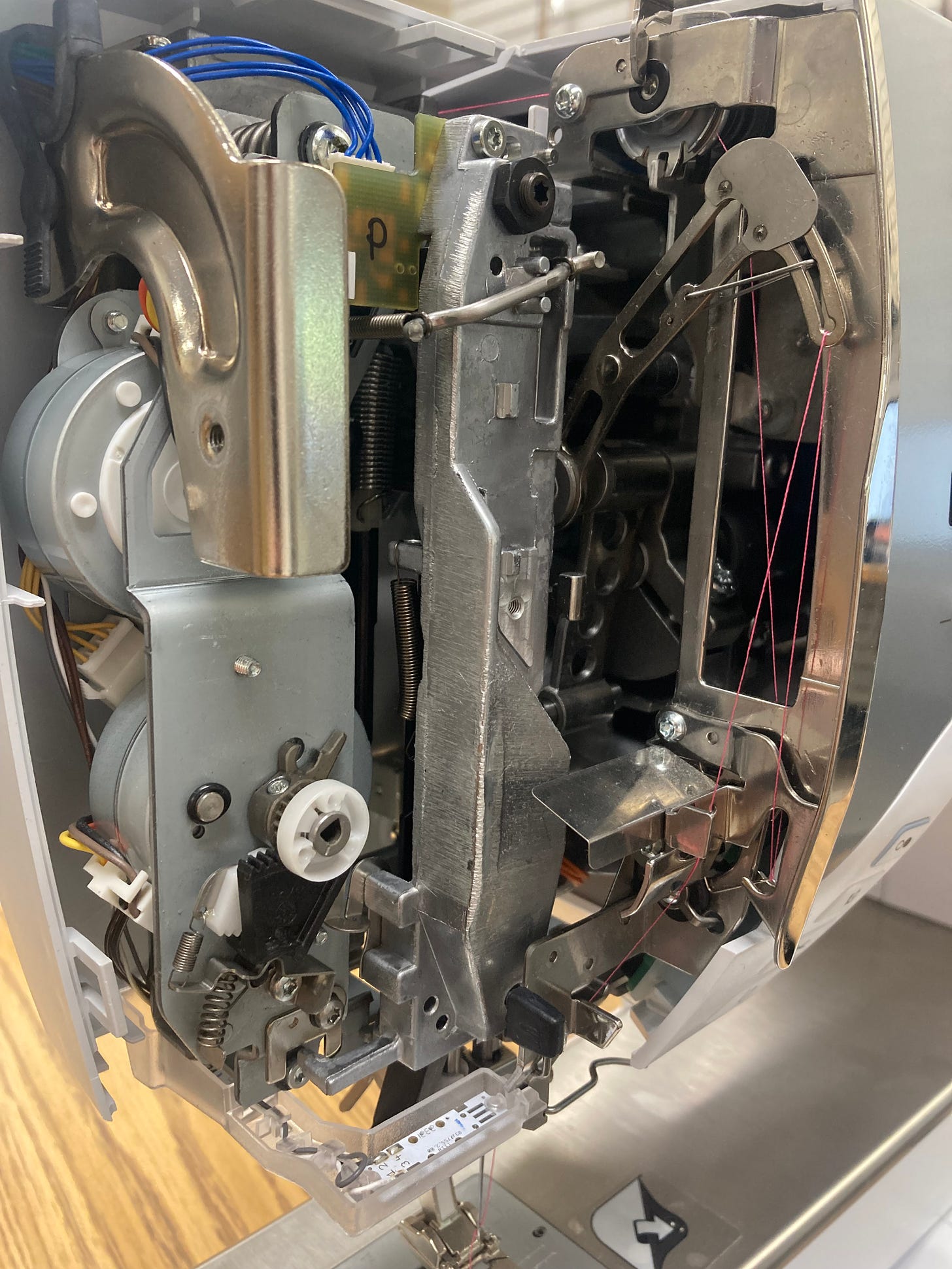

Take a look at your sewing machine and notice the path of your upper thread and all the different contact points the thread makes along its way to the needle:

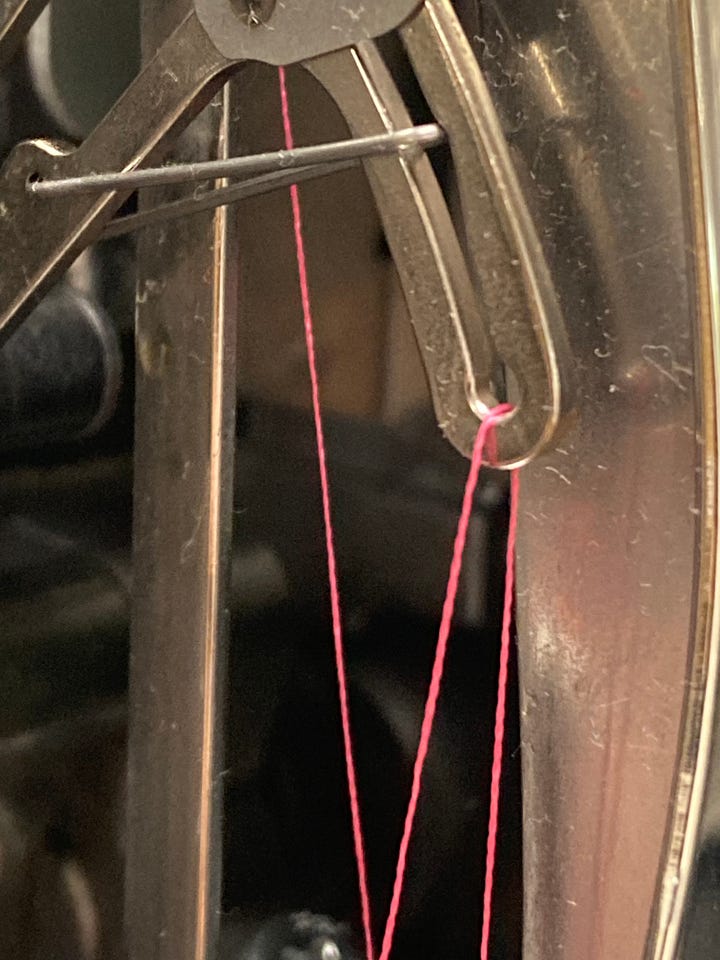

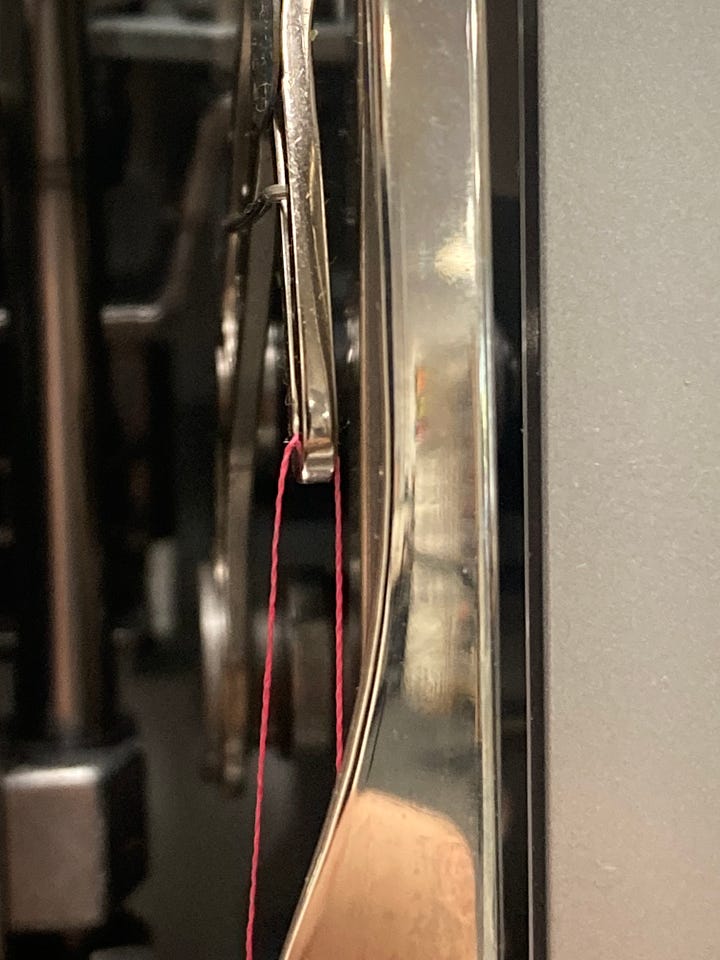

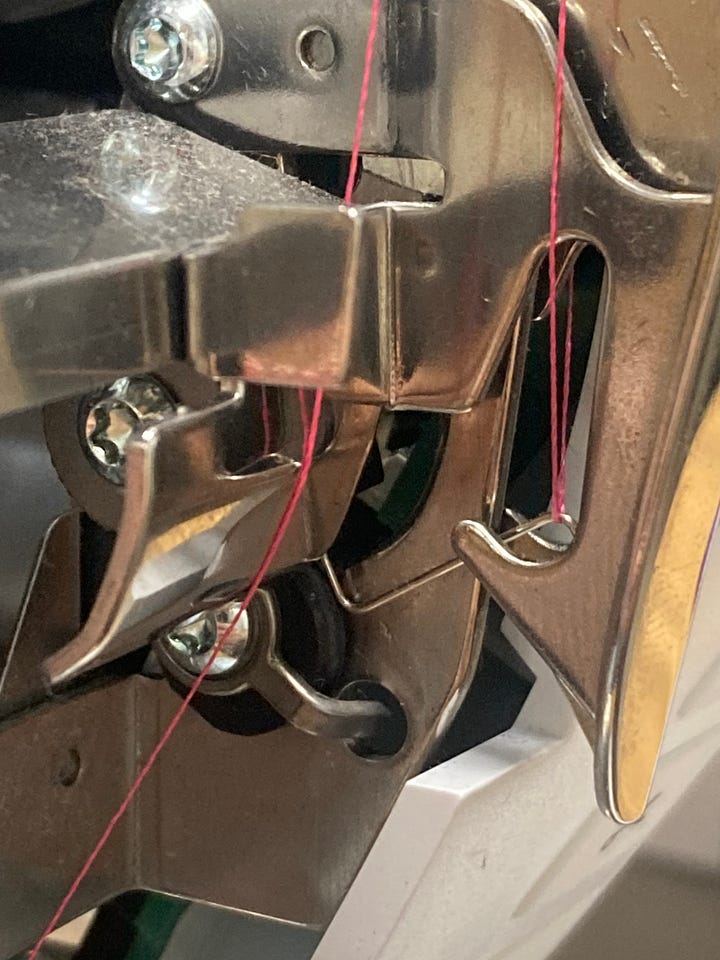

Not only is the thread constantly under tension from the tension discs, it is also constantly making contact with the takeup lever, checkspring, and other various thread guides:

Meanwhile, underneath the needle plate, the thread passes over the bobbin case and hook mechanism during every single stitch, as seen in the video below:

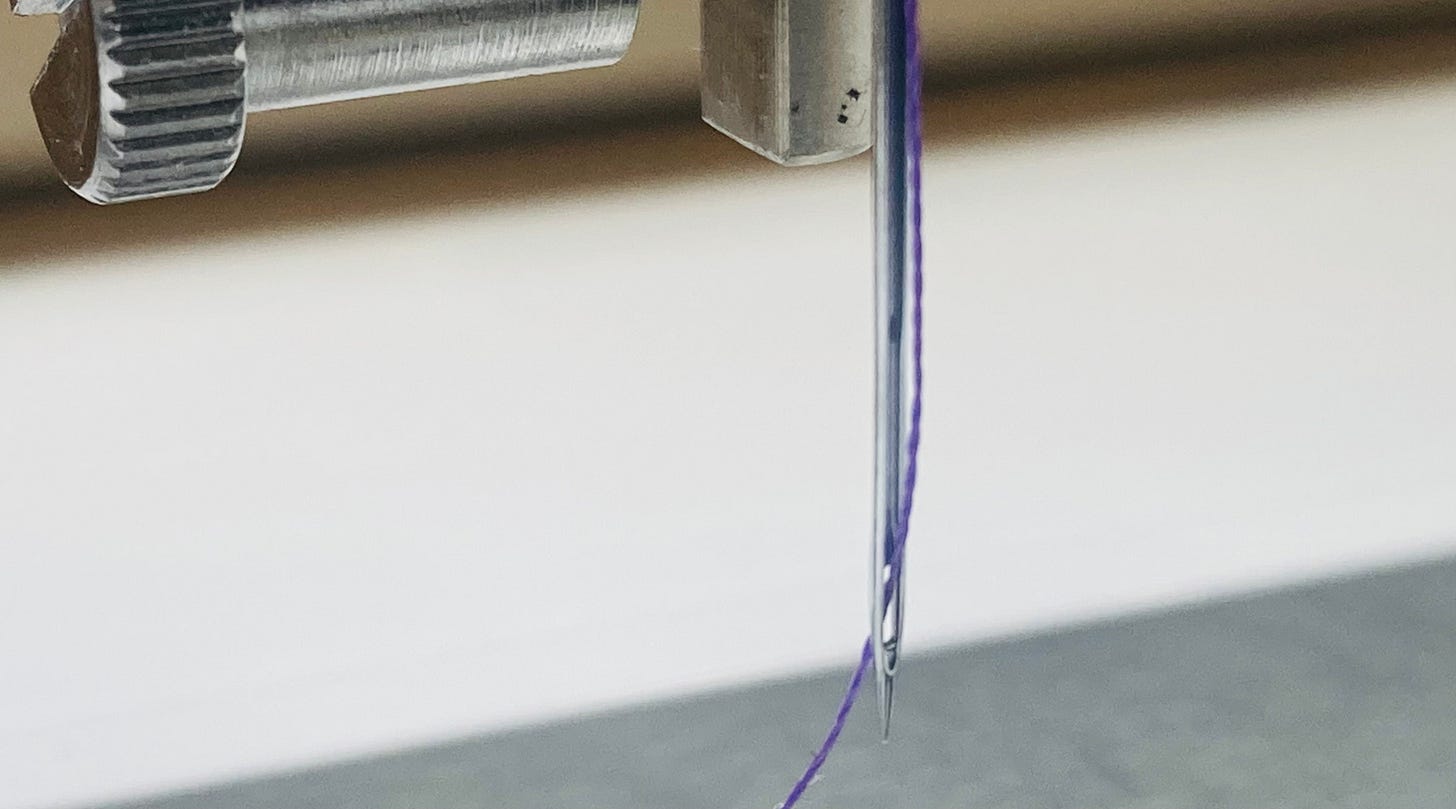

Not to mention, the thread is constantly sliding through the biblically minuscule needle eye:

I bring attention to all these parts of the machine to make a broader point: look how many places the thread slides over as the machine sews. The engineers who design these machines take pains to make all contact points smooth and “thread friendly”, but it is not enough to consistently overcome brittle, uneven thread that falls apart easily under duress/contact. I have had countless experiences where somebody comes into the shop complaining of thread shredding and/or breaking, but when I thread the machine with quality thread, the problem does not repeat itself.

Tension Issues

A sewing machine uses two sources of thread to make a stitch– the bobbin thread and the upper thread spool that goes through the needle. Both thread sources constantly pass between enclosed metal discs as we sew, putting the thread under tension and [partially] determining whether the knot sits perfectly between the fabric we are sewing, or if the knot pokes out of the topside or bottomside of the fabric.

Poor quality thread possesses undesirable characteristics such as being too stiff, too sticky, being uneven, possessing kinks, etc. A thread possessing one or more of these characteristics will have greater drag as it passes through the tension discs in comparison to high quality thread. Even worse, if the characteristic of the thread is not uniform throughout the spool, the drag will vary as we sew, making it difficult to balance tension properly.

From my experience, poor quality thread that is especially stiff tends to manifest as a knot poking out on the underside of the fabric. Part of the reason for this is because the stiff thread causes increased drag on the bobbin case tension discs, which are more sensitive than the upper tension discs. Another reason is that stiff thread creates large misshapen knots that are difficult to cinch up into the fabric. They are often larger than the hole in the fabric itself (the hole pierced by the needle), and therefore get stuck on the underside of the fabric.

So, what is good quality thread?

I cannot vouch for all thread brands because I am not familiar with them all, but I will say a few things here:

The cheapest thread one can possibly buy is probably poor quality thread.

The second cheapest one can possibly buy is probably poor quality thread.

If we have thread so old that the spools are made of wood, we should probably not use that thread anymore.

If we cannot break the thread with our fingers, then it is too stiff to use on our home sewing machine.

If somebody comes into the shop with stitch quality issues and they have a spool of thread on their machine that is neither Aurifill, Mettler, Isacord, Intressa, or Maxilock, then I will unthread the machine and rethread it with a spool from either Aurifill, Mettler, Isacord, Intressa, or Maxilock.

Thank you for reading.

Remember, I come at this topic from the perspective of somebody who sells and repairs sewing machines. My primary concern is stitch quality, since a big part of my job is to make sure that the sewing machine is performing to the best of its ability.

I troubleshoot sewing machines every day at work and often get accused of performing magic because I will sew on the customer’s machine and cannot repeat their stated problem. The truth is that there is no magic at play (most of the time). I simply insert a fresh needle and re-thread their machine with quality thread.

-Cale

What is your view on Gutterman?

I was going to ask the same thing. I have a lot of Gutterman.