Serging with Socrates: A Fun Dialogue on Sergers

Examining the incredible technology and innovation behind Baby Lock sergers.

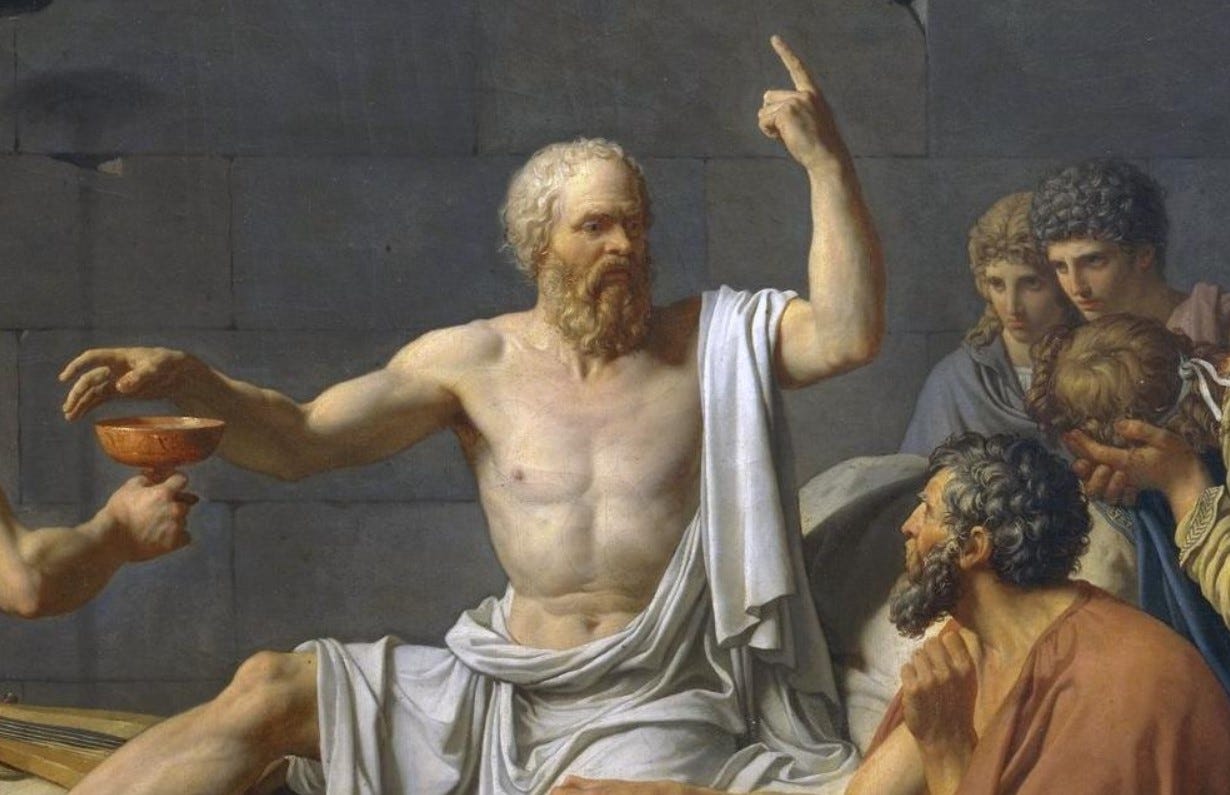

Back in college, I studied philosophy, and one of my favorite courses was Ancient Greek Philosophy, where I enjoyed reading Plato’s Dialogues. Plato, a renowned philosopher of Ancient Greece, shared his ideas through written dialogues featuring Socrates, his teacher, who engaged in thoughtful conversations to explore deep questions about life.

Inspired by Plato’s approach, I've decided to explore sergers in a similar dialogue format—not quite a Socratic Dialogue, but rather a SewingMachineMan Dialogue based on a real customer interaction.

I hope you enjoy.

—Cale

It was just another day at The Sewing Machine Shop, and I was working at my desk when a woman walked in, followed by her husband carrying an old, dusty serger made by the long-defunct sewing machine company, WHITE.

“It needs to be repaired,” she said. “It won’t sew!”

“It’s old,” her husband added with a smile. “Like me.”

He appeared close to 80 years old. I took the serger and placed it on the table beside my desk. They were right—it was old, and it definitely needed repair. The hand wheel was completely frozen, making it impossible to turn.

“We can fix it for you,” I said. “The repair estimate would be around $150-200.”

“Sounds good,” she replied.

“But here’s the thing,” I continued gently, “with these old sergers, even if we fix it perfectly, you'll still run into issues.”

“Like what?” she asked.

“Well, when was the last time you used this serger?”

“Oh gosh, I don't know... it's been at least five years.”

“And why is that?”

She hesitated. “I'm afraid of threading it,” she admitted, embarrassed.

“It’s not your fault,” I assured her. “These old sergers are notoriously tricky to thread. Unlike regular sewing machines, which have just two threads—a needle thread and a bobbin thread—sergers use three or four threads and don't have bobbins. Instead, they have two loopers, an upper looper and a lower looper, each requiring precise threading through five or six tiny thread guides. You need tweezers, good hand-eye coordination, and patience to thread everything correctly.”

“Exactly!” she exclaimed. “That's exactly what threading my machine feels like—a nightmare where I'm trapped in a maze with no way out.”

“And that's not even the worst part,” I told her.

Her husband looked puzzled. “What could be worse than not being able to thread your machine?” He asked.

“Balancing tension,” I explained. “Sergers have tension that's prone to getting out of balance, and correcting it can feel incredibly frustrating.”

“Is it different from sewing machine tension?” he asked.

“Very different. With a sewing machine, you’re dealing with just two threads creating a lockstitch. Ideally, the knot formed by those threads sits neatly between layers of fabric. If the tension is off, you'll see the knot appearing on either the top or bottom side of your fabric. Adjusting is straightforward—if the knot shows on top, lower the upper tension dial slightly; if it shows underneath, raise it. It's basically a tug-of-war between the upper thread and the bobbin thread.”

“That makes sense,” he nodded. “But you're saying sergers aren’t as simple?”

“Exactly. Sergers create an overlock stitch using three or four threads, which is entirely different from a sewing machine’s lockstitch. Instead of forming a tight, central knot, an overlock stitch wraps around the fabric’s edge, providing stretch and flexibility. This makes sergers excellent for sewing knits and stretchy fabrics. However, unlike a sewing machine, balancing serger tension isn't just adjusting a single dial. Each of the three or four threads has its own tension dial, making the process more complex and precise.”

“So, which tension dial do you adjust on a serger when there are three or four different ones?” she asked.

“That’s exactly the issue,” I explained. “Even though I work with sewing machines and sergers daily, balancing serger tension can still be challenging. With multiple threads involved, figuring out which thread—the needle threads, the upper looper, or lower looper—needs adjustment isn't always straightforward. Often, it's a combination of several adjustments. You tweak one tension dial, sew a seam—still not right. Adjust another dial, sew again—still off. Then you realize you might have been turning it in the wrong direction. It's a frustrating cycle of trial and error.”

“I completely understand,” she agreed. “I've experienced that myself.”

“I'm already having nightmares,” her husband joked. “Why spend money fixing something like this? Why would anyone even use a serger?”

“Well, when they're working properly, they're excellent for sewing knits and constructing garments,” his wife responded.

“Exactly,” I added. “They're incredibly useful, especially for stretchy fabrics. But honestly, rather than investing money to repair this older serger, I'd recommend putting that money toward a new one. Modern sergers have evolved significantly, addressing both threading difficulty and tension problems. Now, you can find sergers that use air threading, which threads the loopers instantly with a quick puff of air—no more navigating complicated thread guides.”

“You've got to be kidding!” the husband exclaimed.

“Not at all,” I replied. “There's also a feature called Automatic Thread Delivery, effectively eliminating manual tension adjustments. It provides a consistently perfect stitch without any fiddling.”

“No way!”

“Yes way.”

“I need to see this for myself. Can you show us?”

“Absolutely. Follow me.”

I led the couple upstairs, where all the sergers and coverstitch floor models were displayed. We stopped at the Baby Lock Victory and Baby Lock Acclaim—two innovative sergers equipped with both air-threading technology and Automatic Thread Delivery, replacing traditional manual tension systems.

First, I pointed out how neither of these machines are designed with traditional tension discs:

“Instead of a traditional tensions discs that have a tension adjustment knobs, these sergers are designed with a feature called Automatic Thread Delivery (ATD), arguably the most underrated feature in the sewing world. Rather than putting constant tension on the thread, ATD delivers the required length of thread to form a balanced stitch. This is achieved by an internal mechanism inside the machine-- sliding metal plates that determine the length of the thread delivered into the stitch. Machines with ATD work in a manner that is binary-- thread is either being delivered, or it is not being delivered. The thread is not under constant tension like a sewing machine or the old-school sergers. In fact, there is no tension and therefore there is no tension adjustment that is even possible-- no tinkering, no repeated trial and error. And, on top of all that, ADT is a purely mechanical feature. No computers are involved whatsoever.”

“Can I see these sliding metal blocks you’re talking about?”

“Sure.”

I grabbed a screwdriver and took off the top cover of one of our floor models to expose the ATD mechanism inside the machine:

The couple was very impressed by Automatic Thread Delivery and the consistently perfect stitch these machines produced. Now it was time to dazzle them with the exciting air threading feature.

The Baby Lock Acclaim was threaded up and ready to sew, but I cut the threads and pulled them out. The woman yelped. Her husband laughed. Then I showed her how simple and easy it is to thread the loopers with a gust of air:

“I CANNOT BELIEVE HOW MUCH TECHNOLOGY THEY PUT INTO THESE MACHINES,” her husband exclaimed.

“Should I go get you one?” I asked.

“Yes,” he said quickly.

“Not so fast,” she said. “I noticed you have a couple of Juki sergers, but you only showed me Baby Lock and you mostly carry Baby Lock. I have heard of Juki before, but I’ve never heard of Baby Lock. What is Baby Lock?”

“It’s actually a funny story,” I said. “Because the origin of how Baby Lock came to be is inextricably tied to Juki. Juki is primarily a manufacturer of industrial sewing machines. They are a leading manufacturer of industrial in the modern day, and they were huge in industrials back in the 50’s and 60’s. A common industrial machine is the industrial overlock machine, which is commonplace in factories for finishing edges in garment-making. Like all industrial machines, the overlock machine is really big and really heavy. It sits in a table with a motor mounted on the underside of the table. It is not designed for home use. So, back in the 60’s, home sewing machines were becoming more and more popular, and a couple of engineers at Juki thought it would be a great idea to invent a home overlock machine. They mocked up a design and presented their idea to their superiors, and the lore is that they were laughed out of the room. ‘Nobody is going to want to use an overlock machine at home!’ — that was the prevailing thought, so the idea was shot down. However, the engineers had a strong belief that their idea and their design, they believed it was marketable, so they quit their jobs at Juki and started their own company that made overlock machines for home use— overlock machines that were light and portable, similar to home sewing machines— mini overlock machine— BABY overlock machines— baby overlock machines— thus, the company was named BABY LOCK, that’s how Baby Lock came to be. They got a head start on the competition, plus they have a spirit of innovation embedded in the company’s DNA. In the 90’s, Baby Lock came out with two pieces of game changing technology: Air Threading for the upper and lower looper and Automatic Thread Delivery which replaces the traditional tension system and delivers a perfect stitch every time. Now it’s 2023, and Baby Lock is still King of the Sergers. They are the best. They make ultra-reliable machine that are easy to use and perform incredibly.”

The entire time I tell this origin story, the husband is riveted, sitting on the edge of his seat. Several times he starts to interrupt, but the wife elbows him in the rib to shut him up. When I ended the story, I turned to acknowledge him, and what he was so eager to say really surprised me:

”THAT IS JUST LIKE THE BEATLES!”

“The Beatles?”

“Yes the Beatles!!!”

”The band???”

”Yes!!! Just like Baby Lock. Baby Lock is The Beatles and Juki is Dick Rowe and Decca Records!! You haven’t heard the story of The Beatles audition for Decca Records?”

“I have not.”

“You’re so young! It’s very similar story to Baby Lock. It must have been the early 60’s. The Beatles were relatively unknown at the time, though the band consisted of John Lennon, Paul McCartney, and George Harrison. Their manager wanted to get them a record deal, and eventually he got them an audition with a record company called Decca Records, who were interested in potentially signing a record deal with the band. They auditioned in London but were turned down. Can you imagine? Turning down The Beatles. After the audition, one Decca’s employees, a guy named Dick Rowe, famously decided not to sign The Beatles and claimed that guitar groups are on the way out. So, Decca missed out. The Beatles went on to sign somewhere else and became the arguably the best band in history! Just like Baby Lock, huh? Baby Lock is The Beatles, and the company who rejected them is like Decca Records!”

I laughed. “There’s definitely a parallel between the two.”

That day, the couple went home with a brand new Baby Lock Victory— a great cost-effective choice for both people looking to upgrade their old serger, as well as those who are brand new to serging.

Thank you for reading!

I hope you found the story informative. If you are in the market for a serger, I highly recommend you get a Baby Lock that is designed with both air-threading and Automatic Thread Delivery. You won’t regret it. They are incredibly reliable, easy to use, and perform incredibly. Please feel free to read my Guide to Sergers for more information.

The Definitive Guide to Sergers

What is a serger?

Why would I want to use a serger instead of a sewing machine?

What are the best sergers?

What is the best serger for beginners?

Can sergers do coverstitch?

You might have heard that Baby Lock does not manufacture their own sewing and embroidery machines. This is true— the majority of Baby Lock machines over $500 are made by Brother, while most Baby Lock machines under $500 are made by Janome. With that said, Baby Lock sergers and coverstitch machines are made in their own factory in Yamagata, Japan:

Thank you again.

Please feel free to share this article with your fellow sewists, or browse our archive of other educational sewing machine articles

-Cale

I own a store that sells Baby Lock sergers and I still learned so much from your article ~ so much about sergers, about Baby Lock and about The Beatles. Thank you for writing such an enjoyable read. I’ll be sharing with my staff and customers.

I enjoyed learning the origin of the name "Baby Lock" - I always wondered about it. I bought my wonderful Baby Lock Aria at a Sewing Expo about twelve years ago. I have never felt a need or desire for a serger - chacun a son gout!