Take-Up Stroke: an important aspect of sewing machine design.

A big reason why larger machines are capable of sewing thicker fabric & thread

Greetings everybody,

In this edition of The Sewing Machine Newsletter, I am going to talk about an important aspect of sewing machine design called take-up stroke.

To understand why take-up stroke is important, one must first understand the role of the take-up lever.

Role of the Take-up Lever

The function of a sewing machine is to stitch two or more pieces of fabric together. It accomplishes this by tying a knot between two sources of thread: the bobbin thread and the needle thread. This knot is formed below the needle plate, after the needle travels down through the needle plate hole and begins its upward trajectory.

As the needle journeys downward, the upper thread that you’ve threaded through the needle eye is taut. The needle thread remains taut until the needle reaches its bottommost position (below the needle plate). Then, as the needle is just beginning to rise upwards out of its bottommost position, a thread loop forms at the eye of the needle. Just as the needle rises and this thread loop forms at the needle eye, the hook point of the sewing machine’s hook mechanism comes along and passes through the thread loop. The hook point catches the needle thread loop and takes said needle thread along a 360-degree path around the bobbin case. While riding along this path, the upper thread and bobbin thread form a loose knot.

While all that is happening, the needle continues to travel upward. It rises back above the needle plate and continues to rise until it reaches its highest position. Right after the needle reaches its highest position, the take-up lever swings quickly to its highest position.

During the threading process, the machine’s upper thread source (needle thread) passes through the take-up lever eyelet before it ultimately passes through the needle eye. Therefore, when the take-up lever swings to its highest position, the action of it swinging upward causes the loose knot formed beneath the needle plate to be cinched upwards— up into the fabric we are sewing. If our tension is balanced properly, then that knot will be cinched up and hide in between the multiple layers of fabric we are sewing. That, in short, is how a successful stitch is made. The take-up lever is critical to that process.

The video above shows a beautiful animation of the stitch-making process described above. Around the 40-second mark, the role of the take-up lever is shown clearly.

Setting a stitch with heavy thread and fabric

As it should be understood from the description above, the take-up lever is critical in setting the knot up into the fabric.

But not all knots are created equal!!!

More often than not, sewing heavy material requires that we use a heavier thread. By heavier, I mean that the thread is literally thicker than the thread you would typically use to sew quilts and other cotton goods. Thicker thread may often possess the characteristic of being stiffer. Using thicker, stiffer thread means that the machine will form a physically larger knot.

Once thread reaches a certain thickness, home sewing machines will have trouble taking the thread knot from below the needle plate and cinching it all the way up into the fabric. Instead, the knot will sit on the underside of the fabric, which we consider a poor quality stitch. A key reason why this happens is because the sewing machine we’re using has an insufficient take-up stroke. The distance the take-up lever travels from its bottommost position to its topmost position is not long enough to fully cinch that thick knot all the way up into the fabric.

Larger machines tend to have a longer take-up stroke than smaller machines. Industrial machines are specifically designed with a longer take-up stroke than domestic machines. This increased distance—measured from the take-up lever's lowest position to its highest—allows the machine to pull larger thread knots fully into thick fabrics, setting the stitch securely in place.

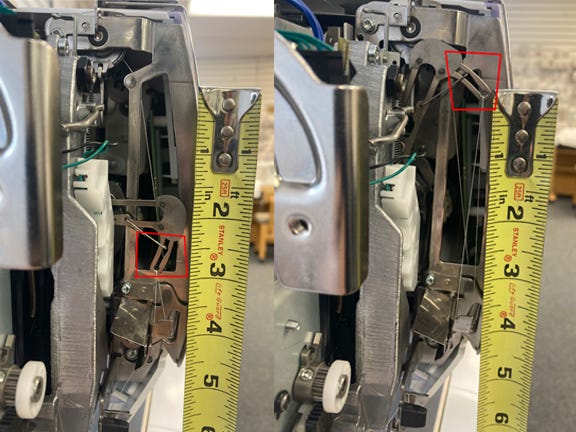

In the photo below, I measure the take-up stroke of an old Adler industrial machine. The take-up stroke is 4 inches long:

Compare that with the Bernina 770 Plus (seen in the photo below), which is one of the more powerful home sewing machines on the market. The take-up stroke is only 3 inches long:

This is one reason why larger machines tend to have a greater ability to sew thicker fabrics and appear more powerful— because larger machines have a larger take-up stroke than smaller machines, and therefore can make good stitches on thicker fabric that calls for thicker thread.

There are certainly factors other than take-up stroke that cause one machine to be more powerful than another machine. The strength of the motor, size of the needle, and quality of the components also play a big role. With that said, from my experience, I’ve seen a lot of sewists hit a crossroads where they want to sew a project that requires heavier fabric and thicker, stiffer thread. Oftentimes their machine has the ability to penetrate the material, but it won’t make a good stitch because the thread knot gets stuck underneath the material. In such instances, insufficient take-up stroke is the culprit.

Thank you for reading!

I hope you found this article helpful.

Please share with your fellow sewists, and don’t forget to explore the archive of other educational article published by The Sewing Machine Newsletter over the past 2 years.

Thank you,

—Cale

Thank you Cale - I teach sewing classes, and it is a common thing for new-never-before-sewists to end up buying a TOY machine (I call them Gutless Wonders) and expect it to sew "everything-under-the-sun" with poor-quality/or too heavy thread/and inappropriate needle. I have to save them from themselves! I provide links to the students so they can get good info, and not waste their time wandering around You Tube or Google.

A timely article for me! I was getting thread knots on the underside of my denim project yesterday while using my Juki TL18QVP with industrial thread. I solved the issue by increasing the tension on the upper thread, and know I know why that worked! Brilliant article, as always. Thank you!