The Sewing Machine Technician's Checklist

a comprehensive list of the things a sewing machine technician does when he services your machine

I first began fixing machines when I was in high school. My dad taught me on the older generation of Pfaff machines— the Creative 7530, Tiptronic 2020, Varimatic 6091, etc. He sold a ton of these Pfaffs in the 90’s and early 2000’s, so it was one of the most common machines in the shop for service. If I could reliably tune-up these Pfaffs and free my dad up for more difficult repairs, then I could legitimately be useful to him and the business. Initially he paid me $20 for every Pfaff I serviced. As I got better and needed less help, he upped my wage to $30 per machine, then $40. Not bad for a high school kid.

In the summer of 2015, my dad hired my good friend, Spencer, and gave him a summer job servicing machines. As I moved on to learn other machines like Janome, Bernina, and Baby Lock, my buddy began his training on Pfaffs, just like I did.

Spencer and I were big fans of the Golden State Warriors basketball team, and 2014-2015 was a huge breakout season for the Warriors. The team won 67 games and finished with the best record in the NBA. Steph Curry won the league’s MVP award. They advanced in the playoffs and represented the Western Conference in the NBA finals against a really good Cleveland Cavaliers team led by Lebron James.

The Finals took place in June, and the Warriors won the series in 6 games. The night they became champions, Spencer and I were watching together. We were absolutely ecstatic. The Warriors had been bad for such a long time, they inflicted so much sports-pain on the fanbase over the years, and now we had a future hall-of-famer in Steph Curry and a bright future ahead. It was a cause to celebrate. It just so happened that I had turned 21 years old about 1 month earlier, so Spencer and I ended up getting hammered. Young and dumb, no foresight and no discipline. I don’t quite remember exactly what we drank. I can only tell you that we were idiots who drank far too much and passed out on Spencer’s parents’ couch.

We had work the next day. Spencer woke me up at 1:00 in the afternoon, frantic. “Cale! Cale, we’re late for work!” I threw a pillow at him, rolled over, and went back to sleep. But Spencer got dressed and rushed into the shop. He grabbed a Pfaff off the repair shelf and went into the repair room. My dad was already in there, performing surgery on an injured machine. Before Spencer could even get the covers off the Pffaf and begin the tune-up, my dad stopped him.

”Good win last night, huh, Spence?”

”Yeah Dan, it was a great win.”

”You celebrate a little bit?”

”Yeah, a little bit.”

”You have fun?”

”Yes.”

”Good, but listen, man— you’re sweating out booze right now. Can’t have you smelling like a bottle of Jack Daniels around our customers. Take the rest of the day off, okay?”

Spencer rejoined me on his parents’ couch and slept off the hangover. Fortunately, both of us made a full recovery and were back at work the next day.

In this edition of The Sewing Machine Newsletter, I am going to show you the exact checklist my dad created to help guide Spencer and me through every sewing machine tune-up we performed. As I get older, a bedrock principle of the world that keeps revealing itself is that everything is more complicated than it appears on the surface. Any given thing contains seemingly endless complexity, and sewing machines are no exception. I think that actually seeing the technician’s checklist will help reveal the depth and complexity of sewing machines themselves, and perhaps deepen our appreciation for the technology and engineering that allows these machines to function the way they do.

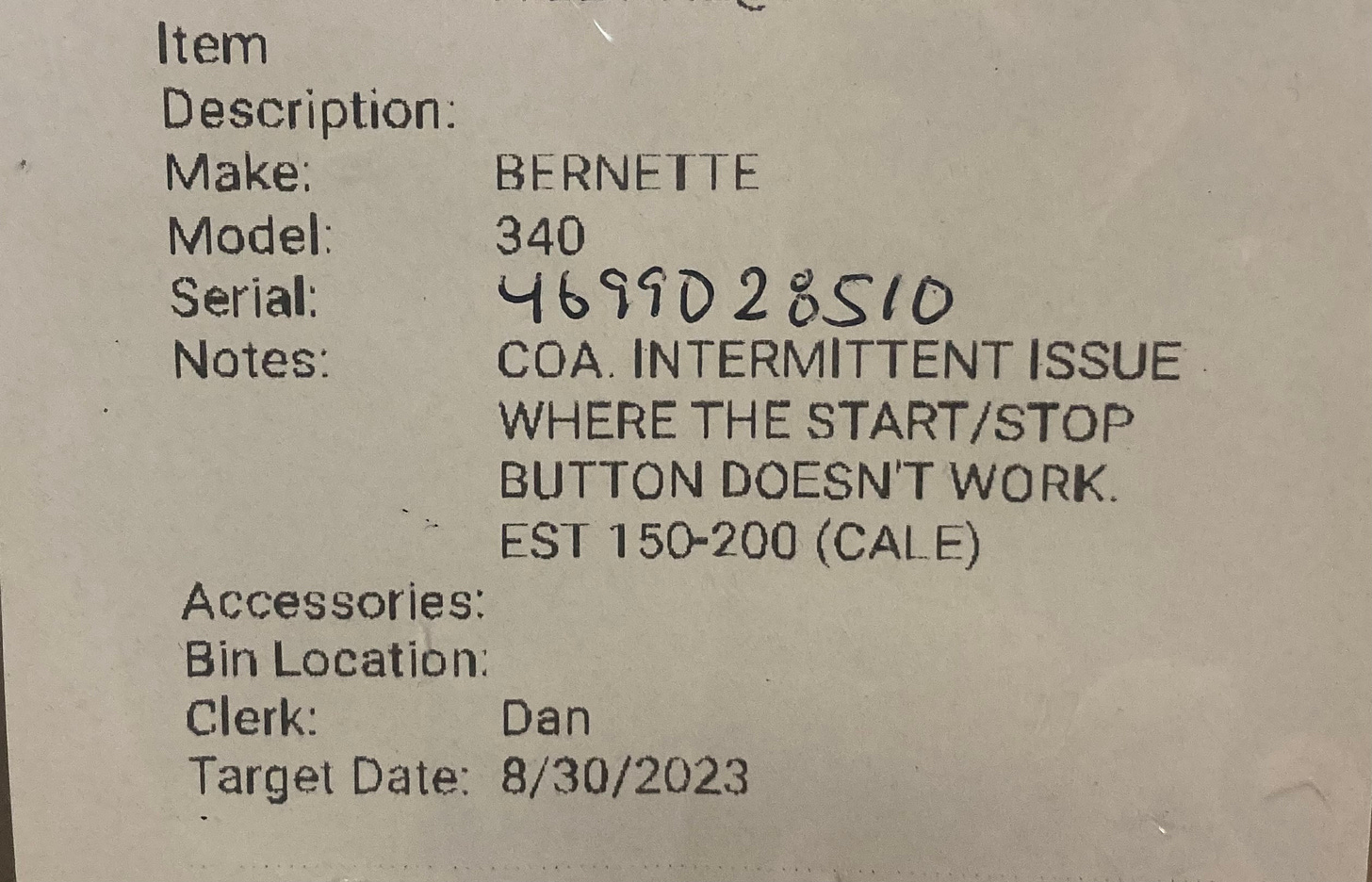

When someone brings their machine to our shop for service, it is usually because the machine has started to have a particular problem. Common problems include:

Poor stitch quality

Skipped stitches

Unusual sounds (squeaking, growling, etc.)

Electronic issues (no power, error messages of some sort, etc.)

Fabric feeds poorly

Needle threader not working

The most important thing a sewing machine technician must remember is to do his work in a precise sequence because one adjustment affects another. For example, you must always check and adjust feed timing before hook timing. Changing feed timing always changes hook timing but changing hook timing does not change feed timing. In fact, most adjustments performed have a direct effect on every other adjustment.

There are basically two main categories of adjustments. They are the feeding system and the stitch-forming system. Then there are additional minor areas such as bobbin winding, needle threader, and electronic calibrations.

The Checklist:

1. Remove all external covers to expose all inner workings

2. Disconnect key electrical connection and remove circuit boards as needed.

3. Clean machine with compressed air and remove all shredded or caught up thread

4. Inspect for worn or broken parts

5. Take up shaft play and gear lash (translation: make loose parts tight again)

6. Lubricate machine (We do not use any grease as a general rule)

Feed System Adjustments:

7. Motor belt tension

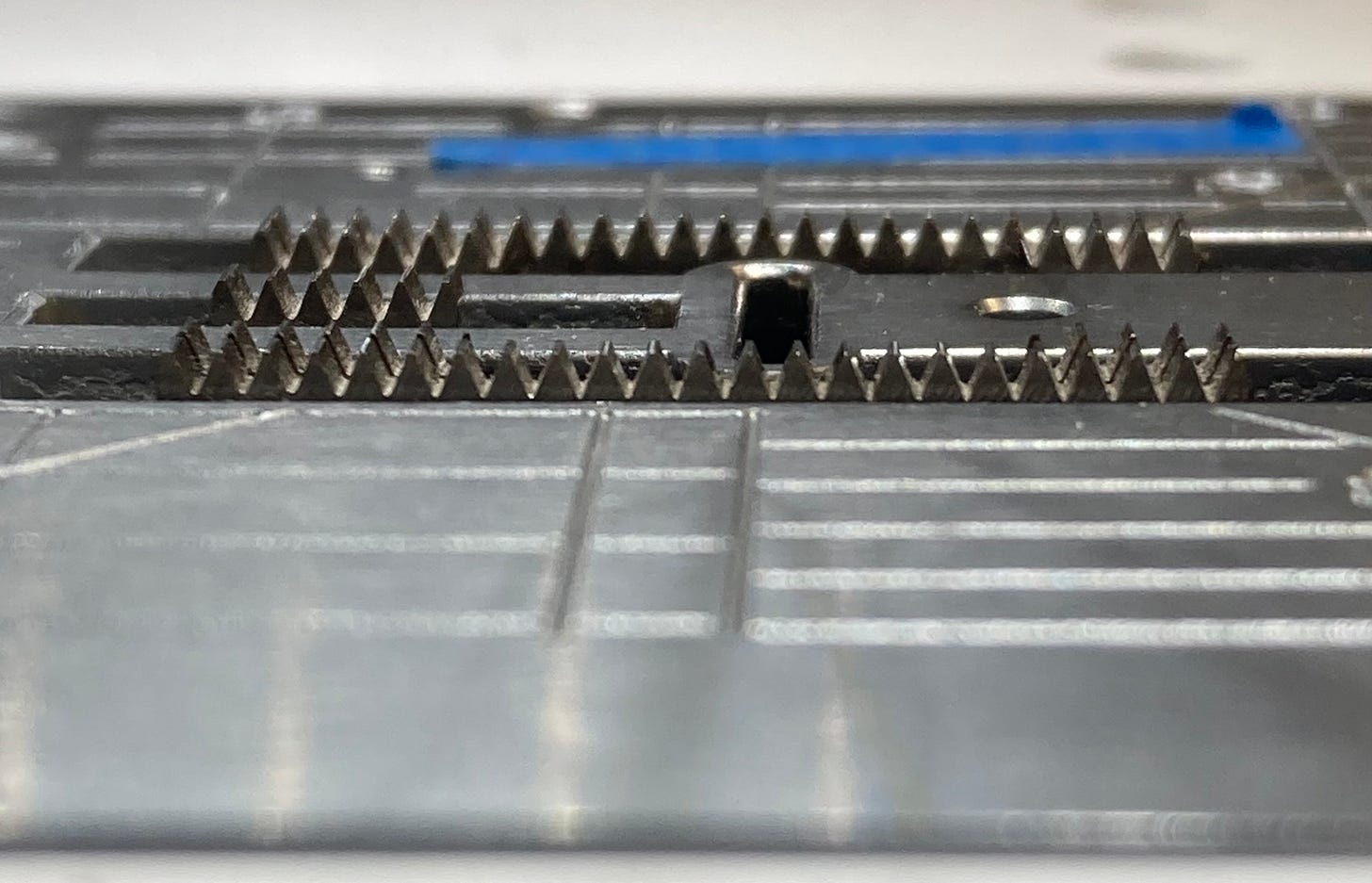

8. Feed dog position in needle plate

9. Timing of feed motion

10. Feed dog height

11 Synchronizer (you wouldn't want needle moving right and left in the fabric)

12. Presser foot alignment and height

Stitch Forming Parts:

13. Position of needle in needle plate (left to right and front to back)

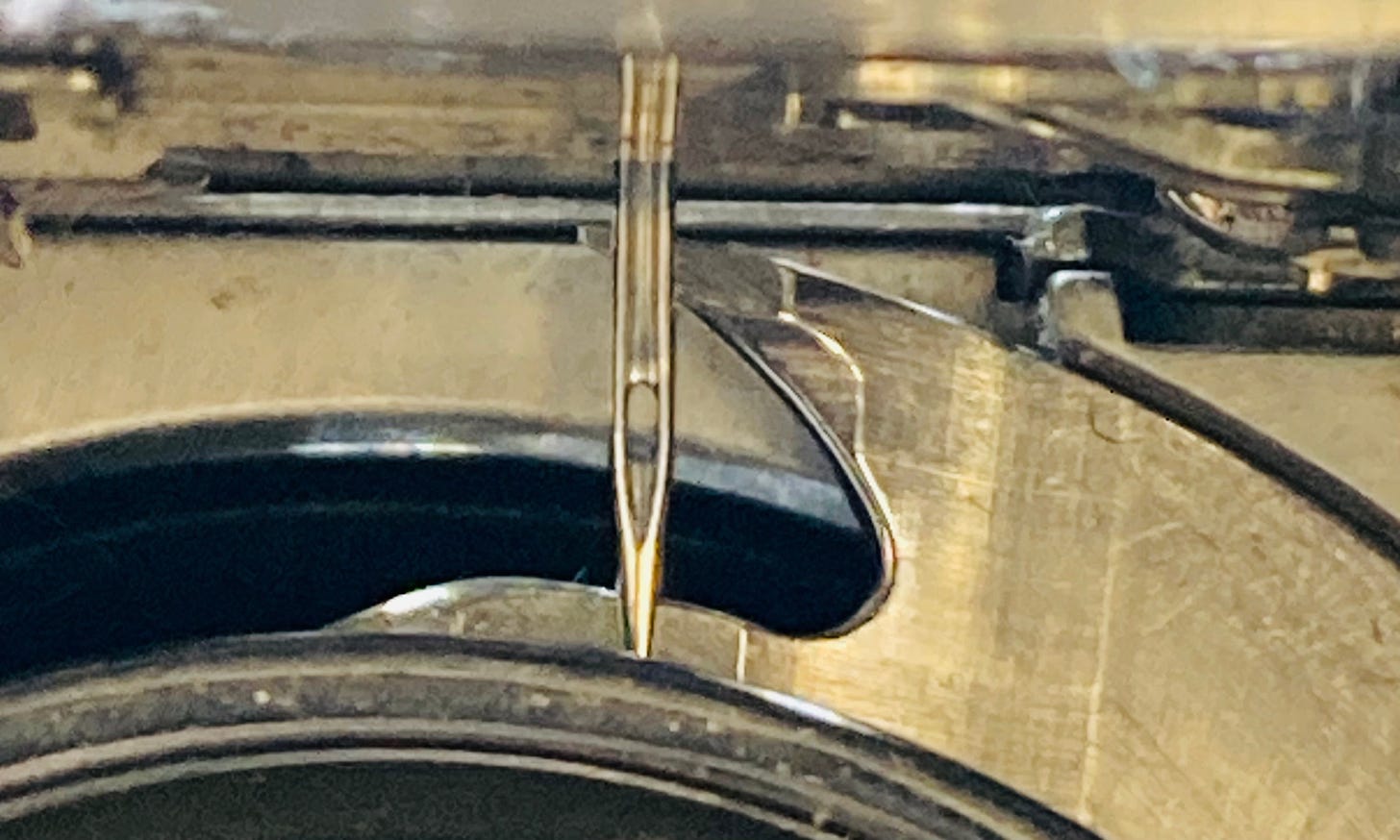

14. Hook to needle clearance (must be close but not touching)

15. Hook timing

16. Needle bar height

17. Bobbin case position finger or bracket

Sew Off Adjustments:

18. Bobbin winder and Bobbin winder auto stop

19. Bobbin Case thread tension

20. Check spring travel

21. Top thread tension

22. Forward and reverse feeding (machine should feed forward the same as reverse)

23. Foot control speed calibration

There are probably 20 other secondary adjustments that I have not listed.

In addition to the checklist, we address all of the customer’s particular issues that prompted them to come to us in the first place.

I hope this article helped communicate exactly what a good sewing machine technician does when he/she services your machine. I also hope it gave you further insight into how sewing machines work. They are incredible pieces of machinery, and one of the most important inventions of the past ~300 years.

Please let me know what you think in the comments, and please share with anybody you know who might find this information interesting or helpful.

Thank you,

-Cale

I loved reading the story about your dad - he sounds like a gentle and wise man. Thank you for an insight into the workings (or not) of our beloved sewing machines. I’m a vintage machine lover and, among others, I have a Bernina Record 730 that I wish I could get you to look at. Alas, its a long way from Australia! 😊

Great articles! Keep up the good work.