Greetings everybody,

In this edition of The Sewing Machine Newsletter, I will compare and contrast two different types of sewing machines being manufactured in 2024: those designed with metal housing versus those designed without metal housing.

Or, in more colloquial terms, tools vs toys.

I have mentioned this concept in the past, but I think it’s worth re-framing and hammering home. I hope you find it helpful.

-Cale

Tool vs Toy

Tool: a device or implement, especially one held in the hand, used to carry out a particular function.

Toy: an object for a child to play with, typically a model or miniature replica of something.

Sewing machines are tools.

A sewing machine is the tool we use to stitch two or more pieces of material together. Unfortunately, in 2024 there is an entire class of machines that are not built like tools. They are built similarly to a child’s plastic toy, and I could make money all day long betting that these machines will not last 5 years.

So, how do I know if a machine is built like a tool or a toy?

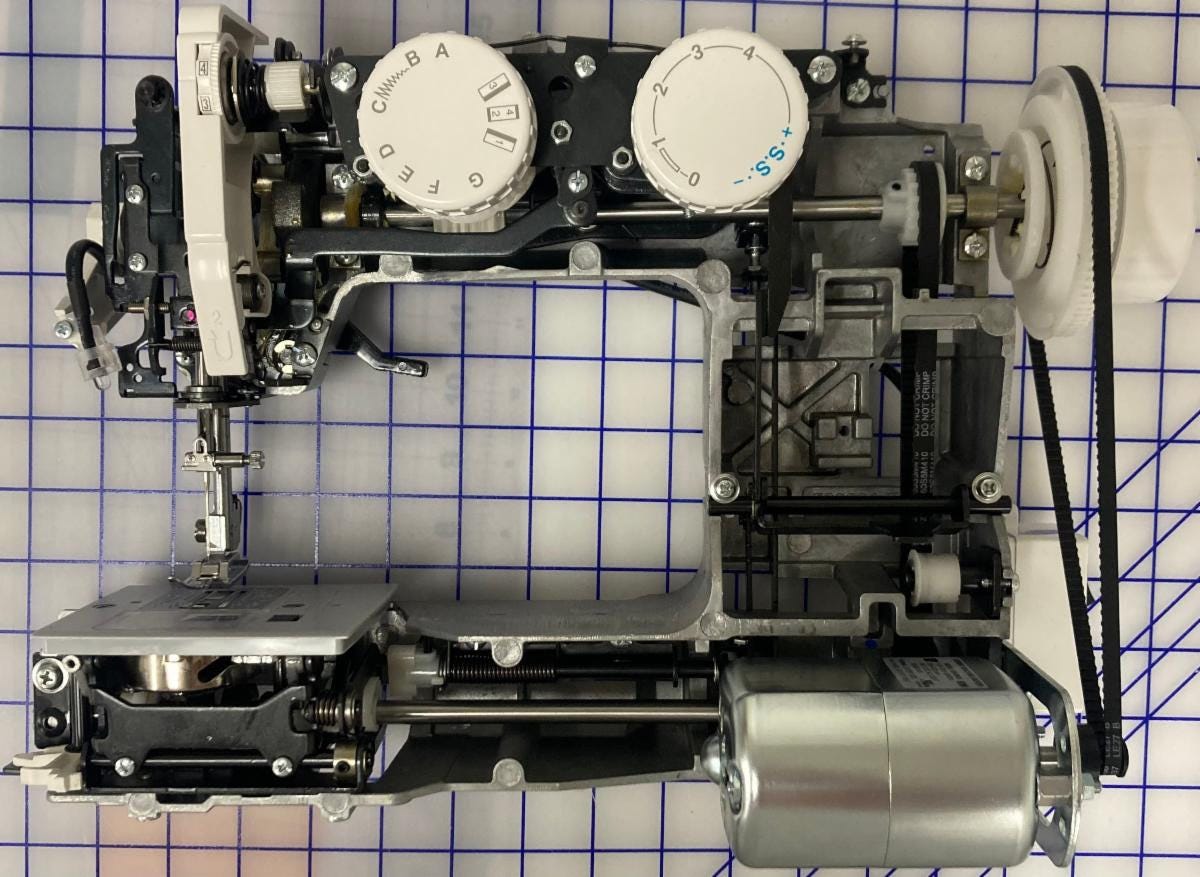

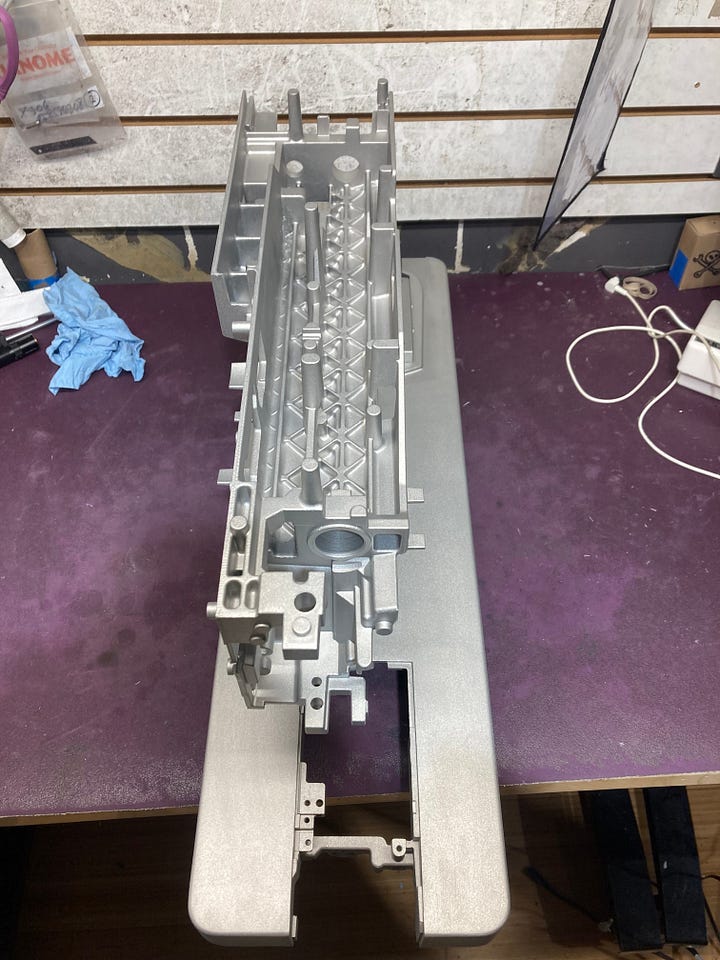

There is one obvious litmus test, and that is whether or not the machine is designed with metal housing. You can see a clear picture of a machine designed with metal housing in the image below:

Think of the housing as a foundation for a home. No home is of high quality if it doesn't have a solid, well-built foundation, and that is what we have here. All the critical components of the machine are attached to a one-piece all-metal housing: the needle bar assembly, hook assembly, feed dogs, upper shaft, lower shaft, etc.

You can actually remove both the front cover and back cover completely and sew on the machine without them:

What does the inverse look like?

You might be wondering how a sewing machine can even be built without metal housing. I can show you.

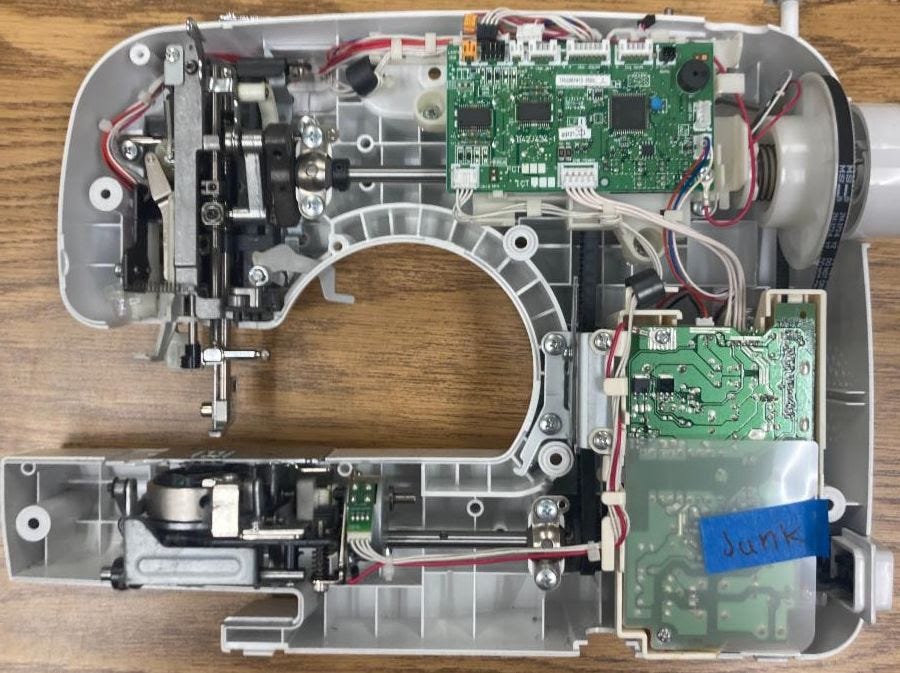

Below is a photograph of a machine that is a best seller on Amazon, given the prestigious label of "Amazon's Best Choice." Have you ever seen the inside of a cheap plastic toy a kid might play with where all the internal parts are attached to the plastic cover? This machine is not so different than that:

Unlike the aforementioned metal housing Janome model, I cannot take the back cover off of this machine because the back cover is the housing. All the internal components are screwed in with self-tapping screws to the back cover of the machine, which is simply a one-piece plastic cover.

Why is this a problem?

The way a sewing machine makes a successful stitch, there is very little room for error. Consider the relationship between bent needles and skipped stitches. If a slightly bent needle can cause failure to make a stitch, imagine how a poorly constructed foundation could cause problems. If all the internal components are housed in the plastic foundation and the plastic foundation bends/warps, every component on the machine can become misaligned.

For example, every time the needle pierces through the fabric, there is a moment of impact. The force of the needle piercing the fabric reverberates up the needle, into the needle bar, into the needle bar mechanism. Ultimately, it is the machine’s foundation that absorbs that impact. Over a long time horizon, that constant impact shouldn’t be a problem if the foundation is made of metal. However, if the foundation is made of plastic, it’s a whole other story. The needle bar can shift out of place. The upper shaft and lower shaft can become misaligned. In other words, a machine with plastic housing is far more susceptible to injury.

Beyond being notorious for not holding up over time, these plastic toy machines are also a pain for technicians to fix. For example, when re-attaching the front cover, if you tighten the screw that holds the two covers together too tight, the entire upper shaft will torque in a way that throws off needle-hook clearance, a setting whose precision is critical for the machine's ability to make a successful stitch. That is why our store has a policy when someone brings in this machine to be repaired: we’ll fix it if you insist, but recommend you take the money you’d spend on repair and instead invest it towards a new machine that will last you 20+ years.

In Conclusion. . . .

Working at The Sewing Machine Shop, I meet quite a few people who own older machines that refuse to consider the possibility of ever owning a modern machine. Most of the time, their reason is that “machines these days are all made out of plastic.”

I understand where they are coming from. They probably gave a modern machine a chance, but were burned by one of these cheap toy models. It’s a shame because modern machines do have a ton of features that make sewing more fun— needle threaders, automatic thread trimmer, pivot function, decorative stitches, electric presser foot lift, throat space, etc. If only they had gotten a tool with metal housing instead!

Unfortunately, some of the most popular machines in the world are toys masquerading as tools, and I don’t see this trend slowing down due to the rampant sewing machine misinformation that pollutes the internet. It was disheartening to see the most recent sewing machine review from Wirecutter, The New York Times online magazine dedicated to product reviews, recommend a machine with plastic housing as the #1 sewing machine in the world for beginners. It is the antithesis of how I have come to view the sewing machine landscape. I value metal housing above everything else, and I genuinely hope to clearly communicate why it’s so important and spread the idea across the wider sewing community.

Thank you for reading.

-Cale

Did you write to the New York Times about that? If not you should.

Really interesting. How can a buyer tell if a machine has a metal housing (without taking it apart)?