What Causes Needle Strikes?

Fabric is only supposed to be fed with the needle out of the fabric. . . .

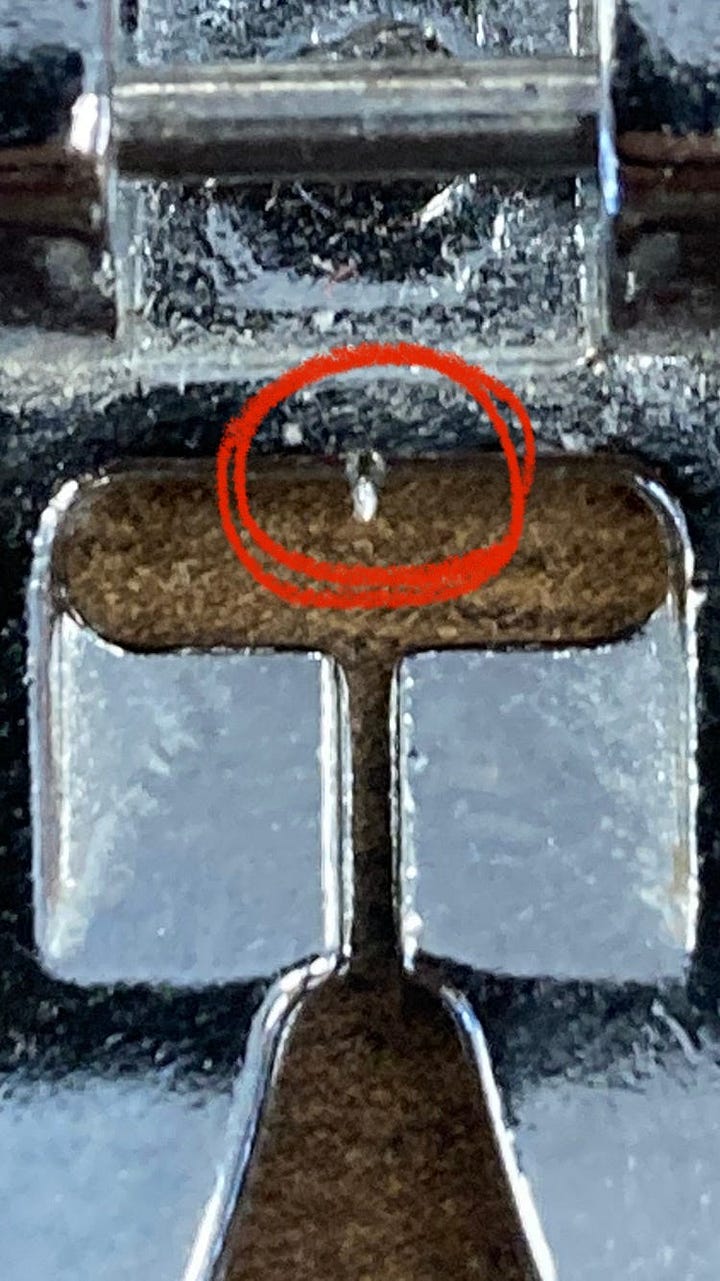

A relatively common issue we see when servicing sewing machines is needle strikes that damage the needle plate hole. This area of the machine can really get chewed up, which may cause stitch quality issues and thread breakage.

Needle Deflection

Needle strikes can occur for a handful of reasons, all of which involve needle deflection. What do I mean by needle deflection? I mean that instead of the needle passing straight down through the needle plate hole as it is designed to do, the needle deflects as it pierces the fabric, changing direction so that it makes contact with the needle plate.

Here are three common causes of needle deflection:

Sewing over a pin or a zipper will cause needle deflection. If we hit a pin or zipper, instead of the needle traveling straight down through the needle plate hole, it will deflect and go down at an angle, where it then has the potential to strike the needle plate.

Needle strikes on the needle plate may occur when we sew through thick material. If the machine is struggling to feed the fabric, and the sewist feels the need to help push the fabric through, we may accidentally push the fabric while the needle is in the fabric. Fabric is only supposed to be fed with the needle out of the fabric, so by manually feeding the fabric through while the needle is in the fabric, we create needle deflection and potentially cause needle strikes.

Feed Timing is a critical setting which, if out of whack, will cause needle strikes on the needle plate. Remember, fabric is only supposed to be fed with the needle out of the fabric. But, if feed timing is off, the feed dogs will feed the fabric while the needle is in the fabric, causing needle deflection. If your feed timing is off, you’ll need to take your machine to a trained technician who can make the necessary adjustments.

Why Are Needle Strikes a Problem?

Needle strikes on the needle plate hole are a problem because thread must pass through that hole in order for the machine to make a successful stitch. Sharp burrs can cause the thread to break.

Even if a burr doesn’t cause thread breakage, it can cause stitch quality issues, as seen in the photo above. Typically small loops on the underside of the fabric are caused by a zero-tension condition, which can usually be solved by a troubleshooting exercise called the pull test. However, we’ve also noticed that small loops can also be caused by large burrs that jet across the needle plate hole.

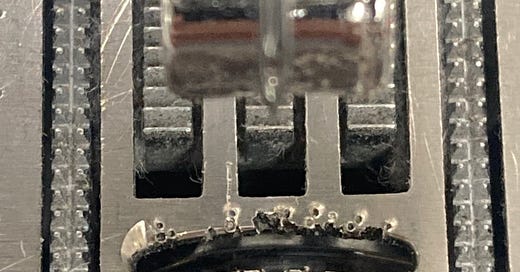

Needle deflection can damage more than just the needle plate hole. It can also damage the machine’s hook point, as well as the presser foot. You can see a gnarly burr on the presser foot in the photos below:

Two Quick Notes:

If you get needle strikes on your needle plate that are causing you problems, try sanding them off with emery cord. If the burrs are really bad, you may need to take it to a sewing machine technician who has more tools and experience grinding those away. However, sometimes a needle strike can cause burrs so bad that the needle plate must be replaced with a new one.

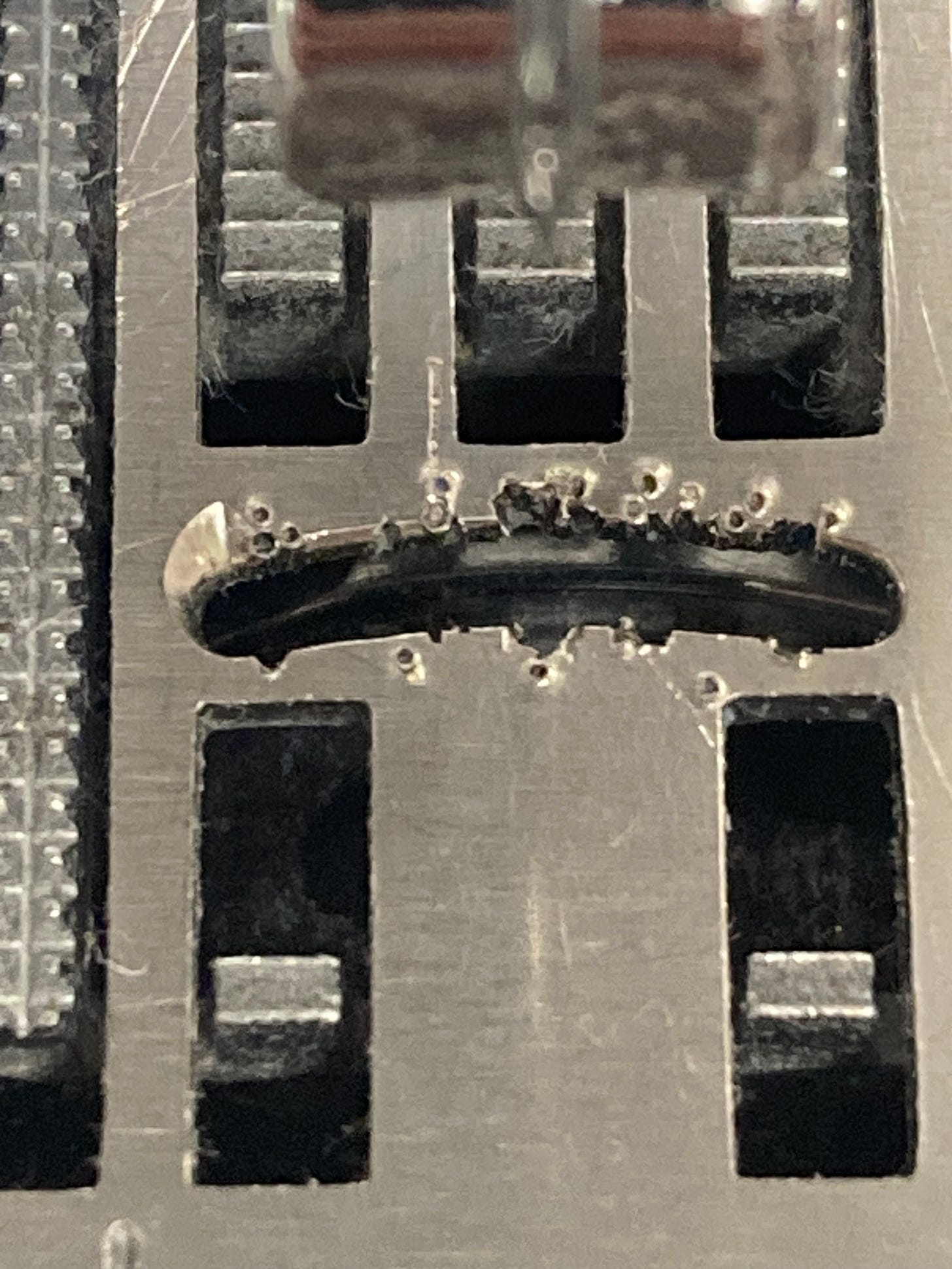

I recommend you do not use titanium needles. They are extremely strong and do not break, which is not a good thing. If your needle hits the needle plate square on, you want the needle to break. They’re relatively cheap and easy to replace. If the needle doesn’t break, a part of the machine will. Look at the photo of the needle plate below, which got chewed up by a titanium needle that shot through the metal needle plate like a bullet. There’s no fixing a needle plate this bad. A new one is needed.

If you like this article, please feel free to share it with your fellow sewists, or drop a comment below.

Also, don’t forget to check out the archive of 50+ articles we’ve published so far in The Sewing Machine Newsletter:

Thank you for reading.

-Cale

Very interesting as I have been guilty of feeding the thick fabric through with obviously too much force at times. I will desist from now on .thank you .i have a clearer understanding now .

I didn’t know about the issues with titanium needles. I love a reason to eliminate choices. So many needle choices with sizes alone.