Recently, we had the pleasure of servicing two Bernina 930 Records and two Bernina 830 Records within a span of a couple days. Last week I examined the details of each service we performed on the two 930 Records to see what we could learn. If you haven’t had a chance to read that article already, I'll attach the link below:

Today I am going to dive into each COA we performed on the two 830 Records. As far as I can tell, the 830 Record is the most popular vintage machine still in use behind the Singer Featherweight. Bernina began manufacturing the 830 Record in 1971, meaning most 830s you see today are over 50 years old. How are they holding up in 2024? Are there any common problems we consistently encounter? What had to be done to each 830 we serviced and why?

Let’s take a look.

Bernina 830 Electronic (1/2)

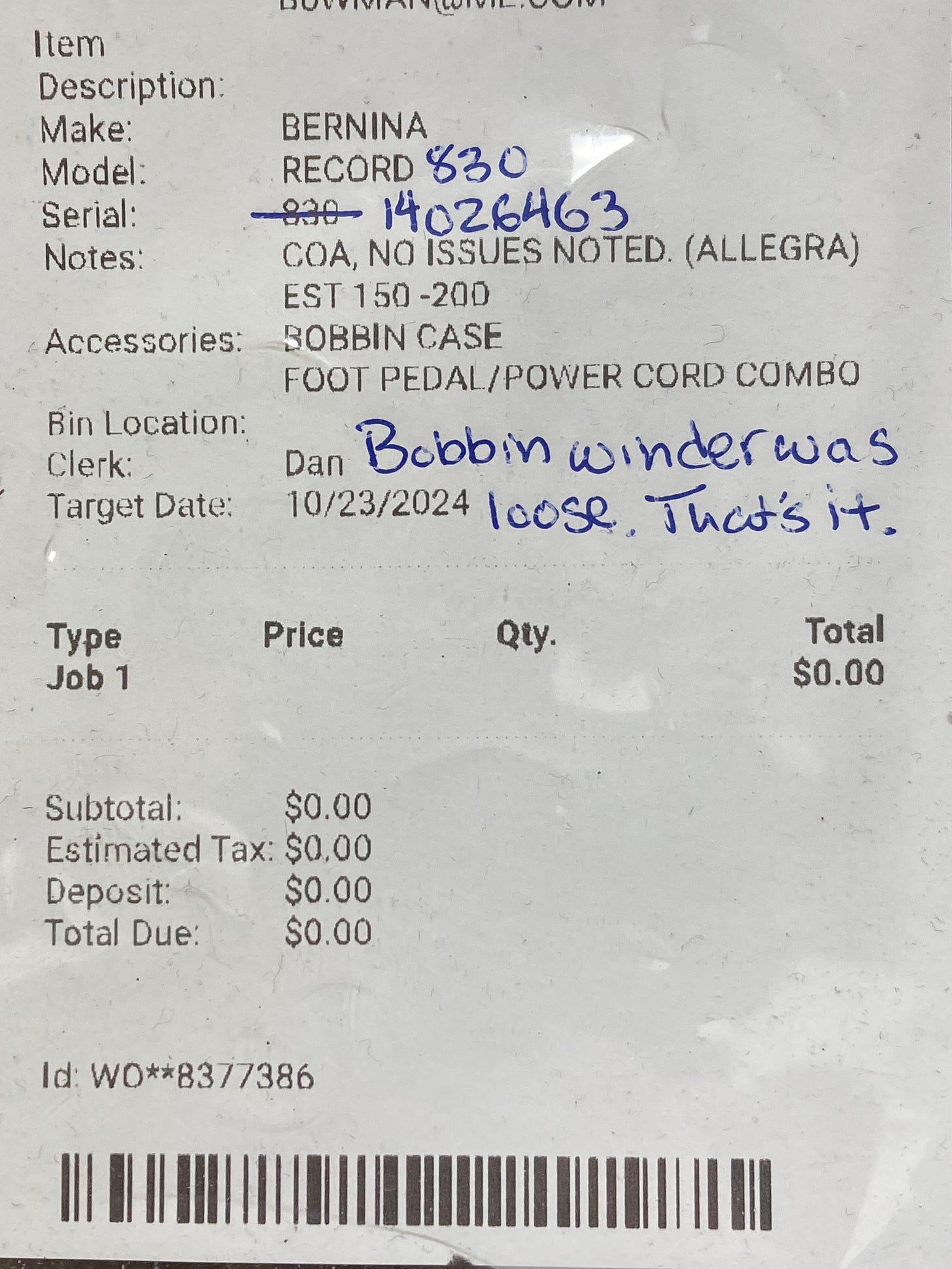

As you can see from the repair ticket below, the owner of this machine reported no known issues, but still wanted us to do a full tuneup (which we refer to as a COA: Clean, Oil, Adjust).

Why would the owner want a service, despite not having any issues with the machine? There are a couple of reasons.

As I mentioned earlier, this machine is over 50 years old. Taking it to be serviced by our technicians is preventative care. There’s a chance that after we clean and oil the machine, we won’t notice anything out of the ordinary when we go through our checklist of adjustments. However, in this particular case we did. As you can see from the technician’s note, the bobbin winder was loose.

The bobbin winder being loose means that the bobbin winder tensioner was not supplying adequate tension on the thread, resulting in the user winding a loose, sloppy bobbin. Our technician, upon noticing this problem, would have tightened the tensioner. If you want to read more about bobbin winding and the key to winding a tight bobbin, please read the article below:

Is the bobbin winder tensioner being loose a common problem we see when we service the Bernina 830 Record? Not necessarily. It’s not un heard of, but I cannot say we see it on the majority of 830 Records— my guess is perhaps 5-10%.

All things considered, this particular Bernina 830 Record was in incredible shape for its age.

Bravo to Swiss Engineering.

Bernina 830 Electronic (2/2)

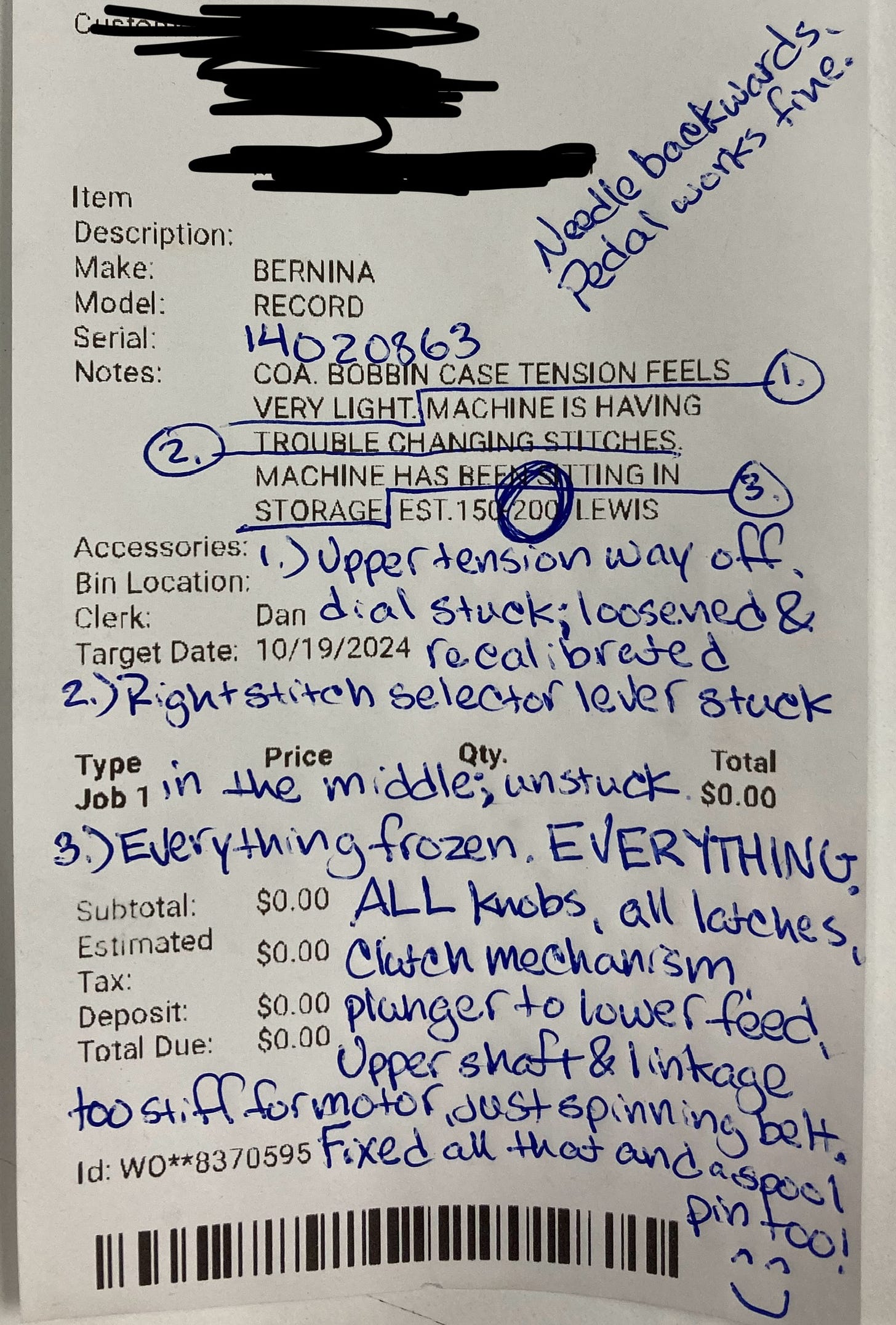

As you can see, this repair ticket is much, much busier than the previous one:

In his notes, our technician makes it clear that everything is frozen.

What does he mean by this? He means, quite literally, that every important part of this machine and every mechanism that controls a given function, was not moving.

The knob that controls stitch width was not moving, meaning that the internal mechanism that controls stitch width was frozen and not able to move the needle from left to right.

The knob that controls the 830’s six-step button hole was frozen, which is also related to an internal mechanism that controls needle position being frozen.

The knob that determines whether or not the feed dogs are raised or dropped below the needle plate— this knob was frozen, meaning the feed dog mechanism was frozen and not able to drop down below the needle plate for free motion/ stippling.

The machine’s upper shaft was stiff and not turning over, making it difficult for the motor to turn the machine over.

The machine’s stitch selection mechanism was stuck, meaning the user was unable to change the stitch pattern.

The handwheel was frozen to the upper shaft, meaning you couldn’t de-clutch the handwheel when winding the bobbin.

The tension dial was stuck, so the technicians had to take it apart, reassemble it, and recalibrate tension to proper settings.

Our technician was able to get this machine humming again by removing all the outer protective covers in order to expose the internal guts of the machine. From there, he lubricated all the parts in need, then spent time moving those parts back and forth by hand, over and over again until they regained full range of movement. The 830 Record is a neat machine because the top cover easily pops off to expose the upper shaft and stitch selection mechanism. Not only does this design allow sewist to appreciate the beautiful Swiss engineering, it also makes the machine very technician friendly.

But what causes such widespread problems in the first place?

It’s simple: an old mechanical machine that has been sitting idle for too long is susceptible to freezing up like this. Take a machine that relies solely on mechanical parts and leave it sitting in the closet for 6 months— there is a good chance that parts will freeze simply from lack of use.

One way to avoid this problem is to take the machine out of the closet about once a month and run it for 5-10 minutes. Even if you don’t actually thread up the machine and sew, turning it on and running it periodically will help prevent the parts from freezing. If you go so far as to oil the machine yourself, even better.

To get a better idea of how all the individual parts of a sewing machine connect to one another, and how one mechanism being frozen can affect another, take a quick glance at the article below:

What can we learn from these two services?

Similar to the 930 Records, the 830 Record still proves to be an exceptional machine. Again, notice that neither of these machines came into the shop for stitch quality issues, nor were there any notes from the technician reporting issues regarding timing, needle-hook clearance, feed dog height, tension, broken gears, etc.

With that said, my biggest takeaway from this exercise is that 50+ year old machines need to be used on a regular basis, or else we risk problems seen in the service of the second 830 Record we examined today. Theoretically, this results in more expensive upkeep. If the owner of an 830 Record only sews one time every a year, and doesn’t run the machine periodically to prevent parts from freezing, the machine may need to be serviced every time she goes to use it. With that in mind, I think it’s fair to say that the 830 Record is not the right machine for a low frequency sewist— and that’s okay! Fortunately there are options for sewists of all types.

Technology has improved in a way where most modern sewing machines are not prone to the widespread frozen parts, so it’s no harm to the machine to take a break from sewing and not use it for six months. For example, most modern sewing machines rely on stepper motors instead of mechanical parts for certain functions like needle positioning and feed dog positioning. Stepper motors are super reliable and do not require oiling. If you’re interested in learning more about stepper motors and the spectrum of computerized machines, I’ve written about this subject in further detail in the article below:

Thank you for reading,

If there are any sewists out there whose machine of choice is a vintage Bernina, or any vintage machine for that matter, I’d love to hear your about your experience, so feel free to drop a comment in the comment section.

Also, if you feel so inclined, please share The Sewing Machine Newsletter with your fellow sewists. I would be very grateful.

-Cale

Great post - I have an 830 Record in beautiful condition, and had another one that I sold to another sewing enthusiast. The 830 is absolutely my go-to machine when I travel, since it fits neatly into its red case, has a ton of accessories, and is great across a wide variety of sewing needs, from very fine silks and chiffons to sewing through multiple layers of denim and vinyl. I love how easily it threads up and how quiet and smooth it is. Both of the 830s I have had were frozen up from lack of use and needed alot of cleaning, oiling, heating, and mechanical manipulation before they got their groove back - but overall, very reliable machines with beautiful stitch quality, great ease of use, tons of available accessories, and decent portability. As you said, they need to be run often enough that the lubrication doesn't get a chance to stiffen,.

Modern machines have a problem with the computer. Once you start using the computer, if you leave them sitting around unused for long periods of time, those components have a tendency to fail. Manufacturers order spare boards before they launch the machine and they guess at how many they may require for a reasonable period of time, say, 10 years. Within a much shorter period of time, the components used on those boards will no longer be available, so in 10 years' time the manufacturer cannot order any more boards to suit that machine. So the modern machine won't seize up in the same way that the old one will, but it's still a paperweight when the board fails and spares are nowhere to be found. With a cheaper machine, the manufacturer may not order as many boards as they would for a more expensive machine. With cheap machines, it's cheaper to throw them away than repair them.