A phrase that keeps popping up in my mind is “sewing machine ontology.”

Ontology is defined as a set of concepts and categories in a subject area or domain that shows their properties and the relations between them. Therefore, we can think of sewing machine ontology as a set of concepts and categories in the domain of sewing machines that shows properties of sewing machines and the relations between them.

Personally, my understanding of sewing machines deepened tenfold when I was able to wrap my head around bedrock sewing machine concepts, rather than simply memorizing specific information. Instead of encountering a problem and trying to think of another time when I encountered that same specific problem, I began to see a problem and trace my steps back toward the overarching sewing machine concept that the problem is tied to.

With that said, this edition of The Sewing Machine Newsletter is dedicated to the concept of the unobstructed thread path. Obstructions to either the upper thread path or lower thread path will absolutely sink your stitch quality, whether it be skipped stitches, thread looping, or thread breakage. It’s an important concept to understand because thread path obstructions can manifest in a relatively wide variety of variations.

Review: How a Stitch is Made

A stitch is essentially a knot that gets tied between two sources of thread— the bobbin thread and the needle thread. The knot is formed below the needle plate, when the needle reaches its bottommost position and begins its trajectory upward. As it begins to move upward, the thread forms a loop at the eye of the needle (on the backside of the needle).

Now, this entire time the machine’s sewing hook has been rotating around the bobbin case and bobbin. The position of the hook point is timed with the position of the needle, so that the hook passes behind the needle (just above the needle eye) when the needle has risen approximately 2-2.5 millimeters above bottom dead center (the needle’s bottommost position).

This precise timing allows the hook point to pass through (or catch) the thread loop as it is formed. After catching the upper thread loop, the hook continues its rotation around the bobbin case, taking the [needle] thread along for the ride. During “the ride”, the needle thread and bobbin thread form a loose knot with each other near the top of the bobbin case.

At this point, the stitch is essentially done being made— all it needs now is to be cinched up into the fabric by the take-up lever, then get properly positioned in the middle of the fabric by way of the upper thread tension and bobbin case tension. It’s an ingenious process that requires precision, without much room for error. In turn, it can all be derailed if either thread path is obstructed.

Whether it be the upper thread source (needle thread) or bobbin thread source, the thread must flow freely from the thread source as your sewing machine sews and makes stitches. There are many different points along the thread path where obstructions can occur and prevent the thread from flowing freely. We’ve actually published quite a few articles on the specifics of these obstructions already, so I will link you to those relevant articles when appropriate. Hopefully, by putting all these examples of thread path obstructions here in one place, we can hammer the concept home.

Spool Cap

Your spool cap ought to be slightly larger than thread spool itself. If the spool cap is smaller than the thread spool, then the thread is susceptible to getting snagged on the rough plastic of the spool. If it’s much larger than the thread spool, then the thread can still get snagged.

A snag serves as an obstruction to the upper thread flowing freely. It can prevent the thread loop from being formed at the eye of the needle, which results in skipped stitches.

Needle Eye Too Small or Thread Too Thick

The thread has to flow freely throughout the stitch-making process. One point where this is tested is at the needle eye.

Thread shredding often occurs because the needle eye is too small for the thread to pass through it freely. There are two potential reasons for this.

The needle eye could be too small (e.g. using a size 65/9 needle with normal 40/50 weight thread).

The thread could be too thick (e.g. using 12 weight thread with a universal 80/12 needle)

Either way, an inharmonious combination of needle eye size and thread weight serves as a thread path obstruction. The needle and thread must be compatible with each other.

Compacted Lint in the Tension Discs

If compacted lint and/or shredded thread becomes wedged between a sewing machine’s upper tension discs, then the tension discs will not be able to close properly. If the tension discs don’t close onto the thread properly, you upper thread will have zero tension.

Where are your upper tension discs?

The thread must pass through closed tension discs in order for a successful stitch to get made. Otherwise, you will get small loops on the underside of your fabric.

The Pull Test

The Pull Test is a troubleshooting test invented by my dad, and it might be the most helpful information I could give a sewist in regard to troubleshooting their machine.

Performing the pull test will tell you whether or not your upper thread is under a zero tension condition. When you pull the thread with the presser foot raised, the thread should pull freely. When you pull the thread with the presser foot lowered, you should feel tension. If you pull the thread with the presser foot lowered and you feel no tension, then your tension discs are not closing on the thread all the way for some reason and you have a problem that needs to be solved.

Another useful aspect of the pull test is that it can indicate other thread path obstruction beyond the tension discs. As I said before, when you pull the thread with the presser foot raised, the thread should pull freely. But what if it’s not pulling freely? What if you feel a snag somewhere?

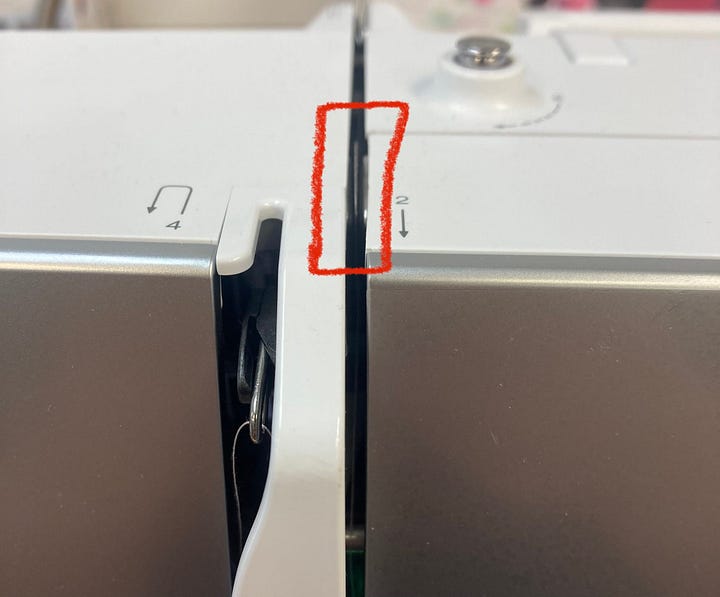

Such situations have arisen numerous times when I’ve troubleshooted sewing machines. It means there is an upper thread path obstruction somewhere that needs to be cleared. It could be the spool cap is too big, too small, or is damaged with a nick that keeps catching the thread. It could be that there is a nick in the plastic shell of the machine that the thread is getting caught on. It could be compacted lint or shredded thread stuck somewhere other than between the tension discs. Either way, the pull test is one of the first things you should do when experiencing stitch quality issues like thread looping or skipped stitches.

Lint/Thread Between the Bobbin Case Tension Discs

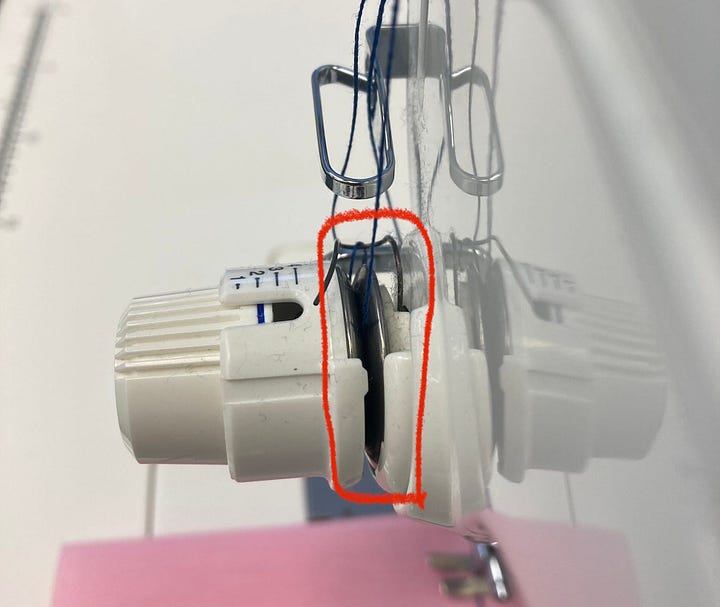

Just like the upper thread path needs to be clear of obstruction, so does the bobbin thread. And, just like compacted lint can obstruct the upper tension discs from closing properly, it can cause the same issue with the bobbin case tension discs (circled in red below).

If compacted lint and thread gets stuck between those discs, the discs will not close properly. If the discs don’t close properly, then the bobbin thread will have zero tension and get sucked up to the top of the fabric, manifesting as small loops (a.k.a. eyelashes). If you ever get these small loops on the topside of your fabric, clear out any obstruction between these discs by using canned air or something thin like a pin or needle.

Needle Strikes on the Needle Plate & Bobbin Case

Needle strikes on the needle plate, bobbin case, and presser foot can serve as thread path obstructions.

Similar to the spool cap, all of these parts are designed to be extremely smooth because the thread slides over across their surfaces during the stitch-making process. Sharp burrs born from needle strikes (as seen in the photos above) can create all sorts of problems, such as thread breakage or unwanted thread loops.

Poorly Wound Bobbin

As strange as it sounds, a poorly wound bobbin is an obstruction the bobbin thread itself.

You want the thread to flow freely from the bobbin. There is a portion of the bobbin thread that is “next up” in the sense that it is the next portion of the bobbin thread that will be used to make a stitch. When you wind a good bobbin where the thread is tight and even, the portion of the bobbin thread that is “next up” should flow freely from the bobbin as it partakes in the stitch-making process. However, if you wind a loose sloppy bobbin (as seen in the photo above), the thread that is “next up” may be buried underneath other loose threads due to the bobbin being wound sloppy and uneven. Therefore, the thread that is “next up” has to pass through the thread it is buried under, which essentially acts as an obstruction in the bobbin thread path.

Thank you for reading!

If you found this article helpful, please feel to subscribe, leave a comment, and share with you sewing friends.

-Cale

Thank you for a great artikel very informative

Someday a book should be written. (Maybe just collect your columns and sell as ebook we can print ourselves. No money in publishing. )